Electrode for electrolysis, electrolytic cell, and method for manufacturing electrode for electrolysis

A manufacturing method and electrode technology, applied in the direction of electrodes, electrolytic components, electrolytic process, etc., can solve the problems of high overvoltage, time-consuming, etc., and achieve the effect of reducing overvoltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

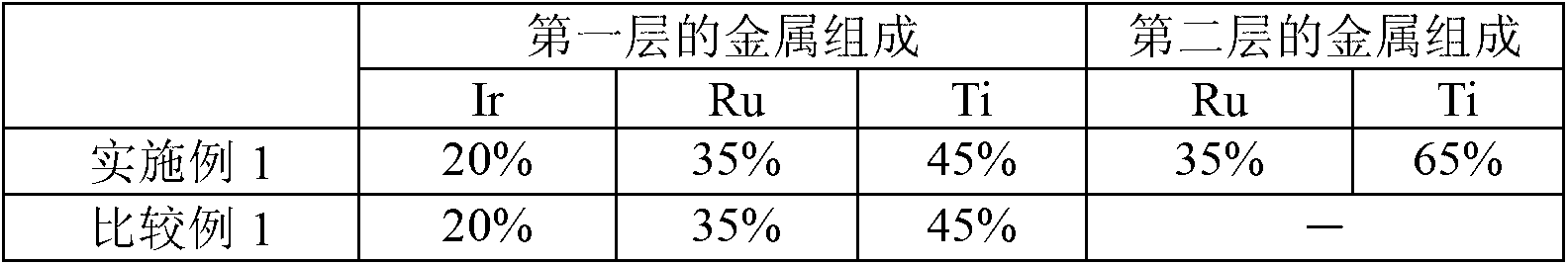

Embodiment 1

[0116] As the conductive substrate, a stretched titanium substrate having a large pore size LW of 6 mm, a small pore size SW of 3 mm, and a plate thickness of 1.0 mm was used. The stretched substrate was fired at 540° C. for 4 hours in the air to form an oxide film on the surface. Thereafter, acid treatment was performed at 85° C. for 4 hours in 25% by mass of sulfuric acid to form fine unevenness on the surface of the conductive substrate, thereby performing pretreatment.

[0117] Next, in such a way that the molar ratio of ruthenium, iridium, and titanium is 35:20:45, an aqueous ruthenium chloride solution (manufactured by Tanaka Precious Metals Co., Ltd., ruthenium concentration: 100 g / L) is cooled to below 5°C with dry ice, while stirring Next, titanium tetrachloride (manufactured by Kishida Chemical Co., Ltd.) was added little by little, and then an aqueous solution of iridium chloride (manufactured by Tanaka Precious Metals Co., Ltd., iridium concentration was 100 g / L) w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com