Shape memory alloy friction composite vibration isolator

A technology of memory alloy and memory alloy spring, which is applied in bridge parts, infrastructure engineering, building components, etc., can solve the problem of poor self-resetting and self-adaptive ability of vibration isolators, single vibration isolation direction, poor fatigue resistance and corrosion resistance and other problems, to achieve the effect of vibration control and self-resetting, reducing the concentration of force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

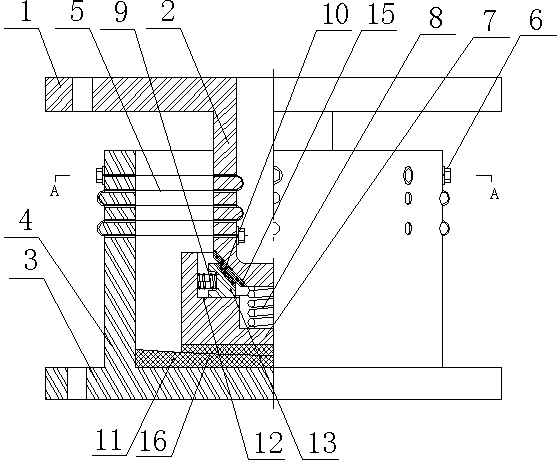

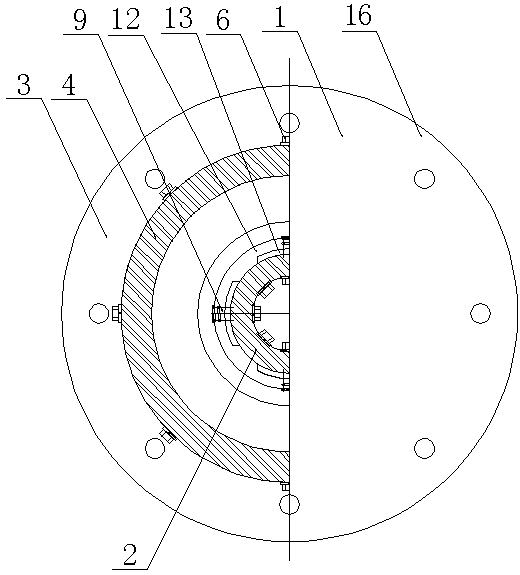

[0029] like figure 1 , figure 2 and image 3 As shown, a shape memory alloy friction composite vibration isolator includes an inner cylinder 2 connected to the upper flange 1 and an outer cylinder 4 connected to the lower flange 3, the inner cylinder 2 and the outer cylinder 4 are coaxial, and the inner cylinder 2 The cylinder 2 and the outer cylinder 4 are radially connected by eight groups of austenitic shape memory alloy strands 5 arranged symmetrically on the circumference, and each group of the austenitic shape memory alloy strands 5 is arranged in five layers. The end of the austenitic shape memory alloy strand 5 is fixed by the strand fixing snap ring 6; a slidable inner cylinder base 7 is arranged under the inner cylinder 2, and an axial austenite is arranged inside the slidable inner cylinder base 7 Shape memory alloy springs 8 and several groups of radial austenitic shape memory alloy springs 9, the radial austenitic shape memory alloy springs 9 can be set to four...

specific Embodiment 2

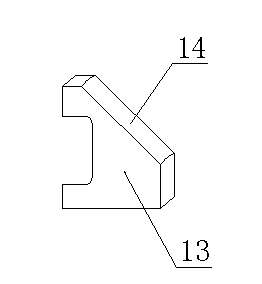

[0036] like Figure 4 As shown, the difference from the first embodiment is that: the upper side of the slidable inner cylinder base 7 is provided with an inner hole 17 of the mounting seat for installing the radial austenitic shape memory alloy spring 9, and the radial austenitic The front end of the shape memory alloy spring 9 is provided with a slider 13 protruding from the inner hole 17 of the mounting seat.

specific Embodiment 3

[0037] The difference from Embodiment 1 or 2 is that: the austenitic shape memory alloy strands 5 are symmetrically arranged in six groups on the circumference of the inner cylinder 2 and the outer cylinder 4, and each group of the austenitic shape memory alloy strands 5 Set to five layers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com