Method for measuring cavity mode split of vertical cavity surface emitting laser under room temperature condition

A vertical cavity surface emission and laser technology, which is applied in the direction of testing optical properties, can solve the problems of high equipment and cumbersome test steps, and achieve the effect of simple measurement equipment, avoiding errors, and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

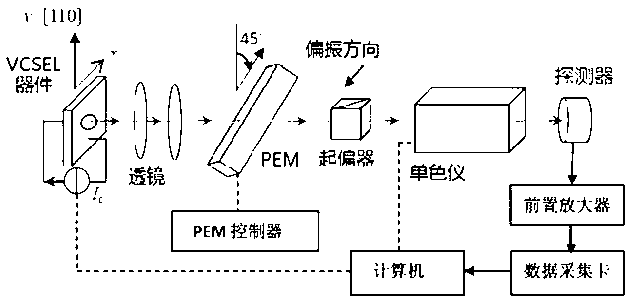

[0034] The invention provides a method for measuring cavity mode splitting of a vertical cavity surface emitting laser at room temperature, comprising the following steps:

[0035] S01: Provide a vertical cavity surface emitting laser, and sequentially arrange two focusing lenses, a photoelastic modulator, a polarizer, a monochromator and a detector on the optical path of the vertical cavity surface emitting laser;

[0036] S02: providing a pulsed current source to inject forward current into the vertical cavity surface emitting laser;

[0037] S03: adjusting the size of the light entrance slit of the monochromator;

[0038] S04: A controller providing a photoelastic modulator controls the photoelastic modulator to set a wavelength value and a phase delay value;

[0039] S05: providing a computer to control the monochromator to perform wavelength scanning;

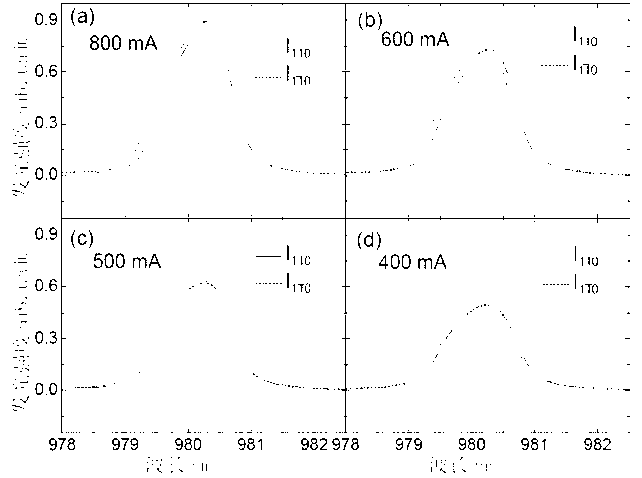

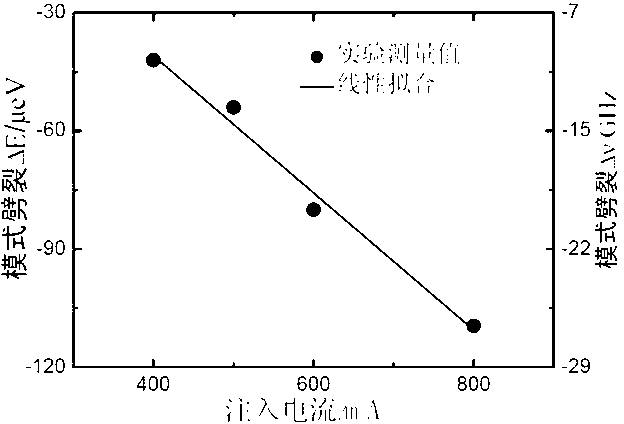

[0040] S06: Provide a data acquisition card for the light intensity value I obtained by the detector under a group of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com