Optical fiber with polarization function

An optical fiber and functional technology, applied in the laser field, can solve the problems of low production efficiency, high grinding accuracy and high coating requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

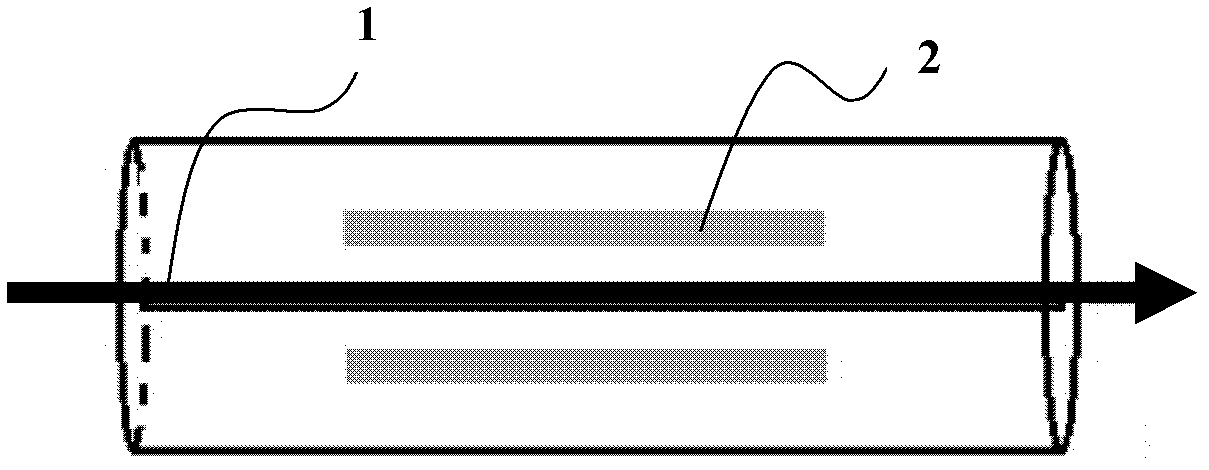

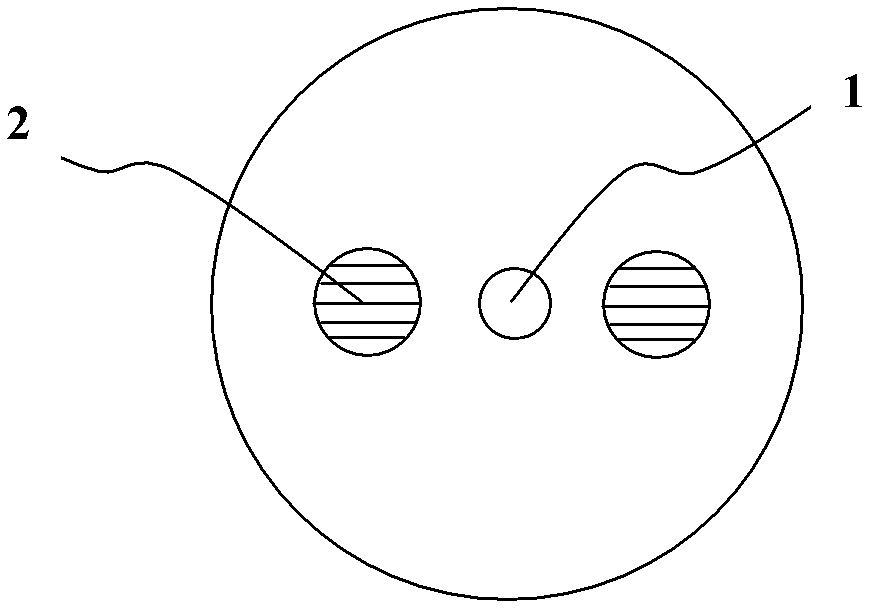

[0023] The working principle of the present invention is: under the action of the focused femtosecond pulsed laser, the quartz material will undergo multiphoton absorption at the laser focus and the action area of the quartz material to generate plasma. When the plasma reaches a certain density, the material will be damaged, thereby changing The optical properties of quartz materials, and outside the laser focus, the laser intensity does not reach the multiphoton absorption threshold, and the material will not be damaged, so precise positioning processing can be realized within the material. Femtosecond pulse lithography with different parameters will produce two kinds of modification in quartz materials, that is, the change of refractive index or the induction of periodic nanostructures. The polarized light-guiding performance of the nano-grating produced by the parametric laser is also different. In the cladding near the core of the ordinary silica fiber, the nano-grating t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com