Ignition coil having coupling device

A technology of ignition coil and connecting device, applied in the direction of engine ignition, spark ignition controller, spark plug, etc., can solve the problems of limited selection, inability to ensure ignition coil, etc., to ensure prestress, cost economy, continuous and reliable, and prevent surrounding media. and environmental impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

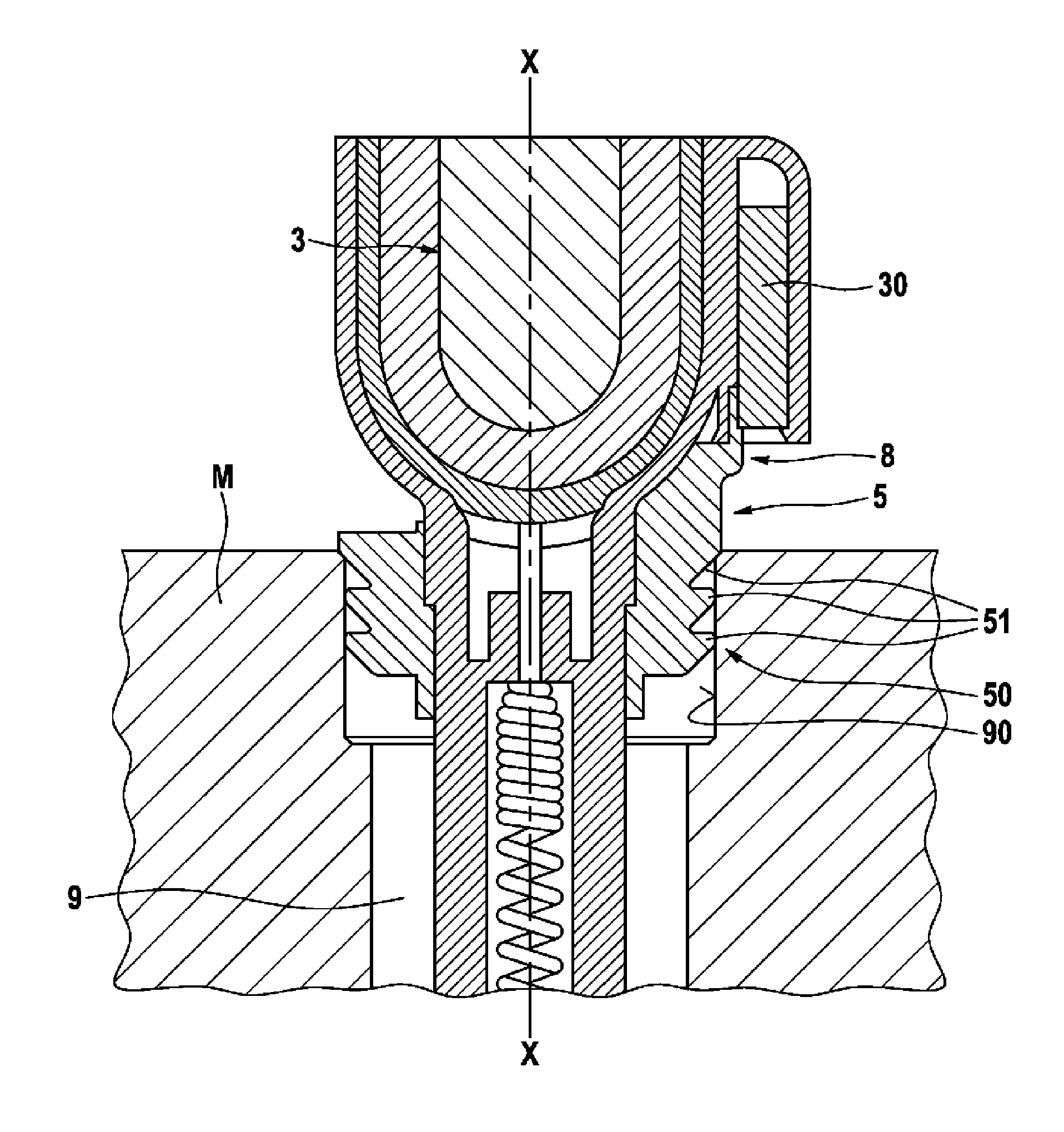

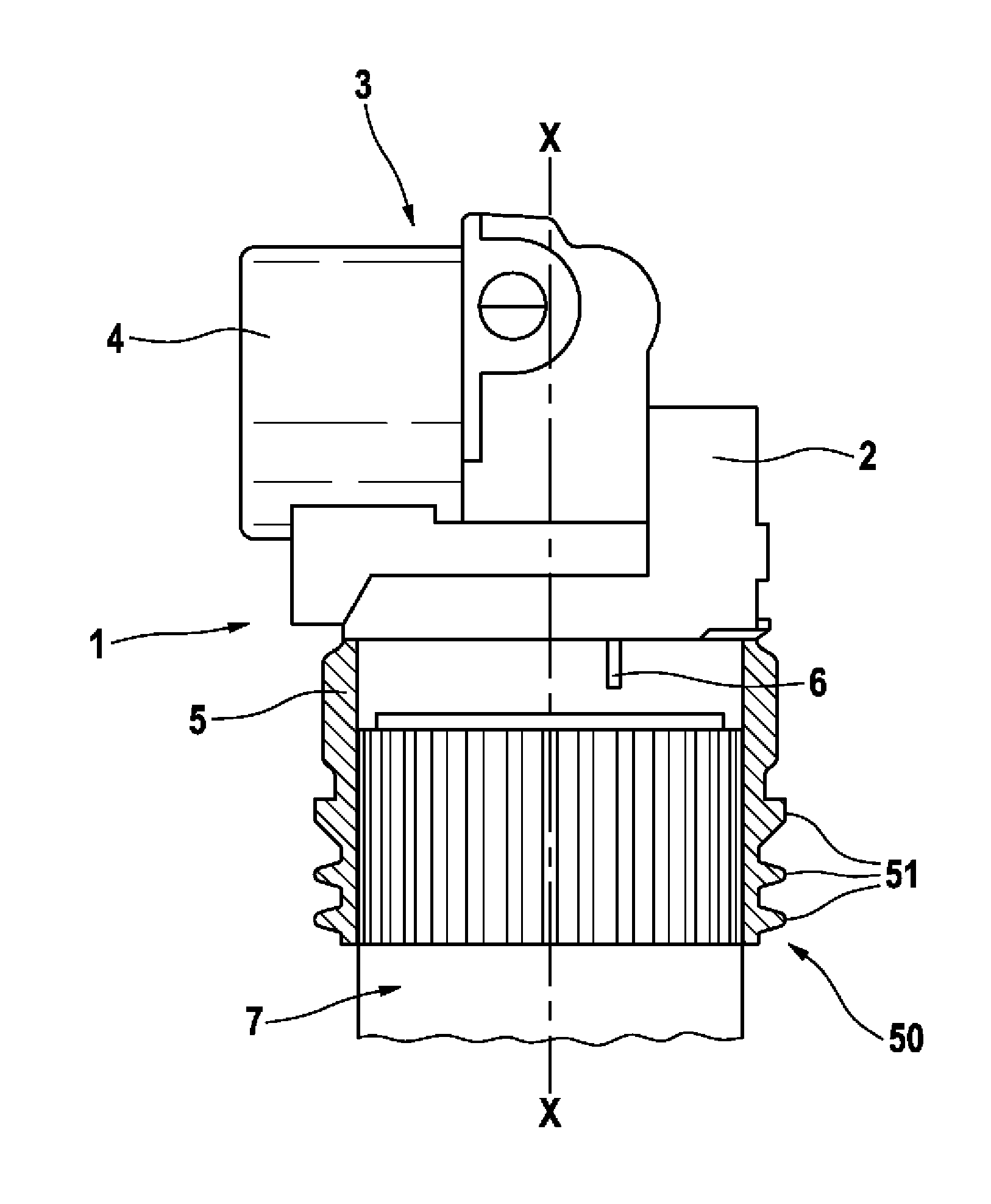

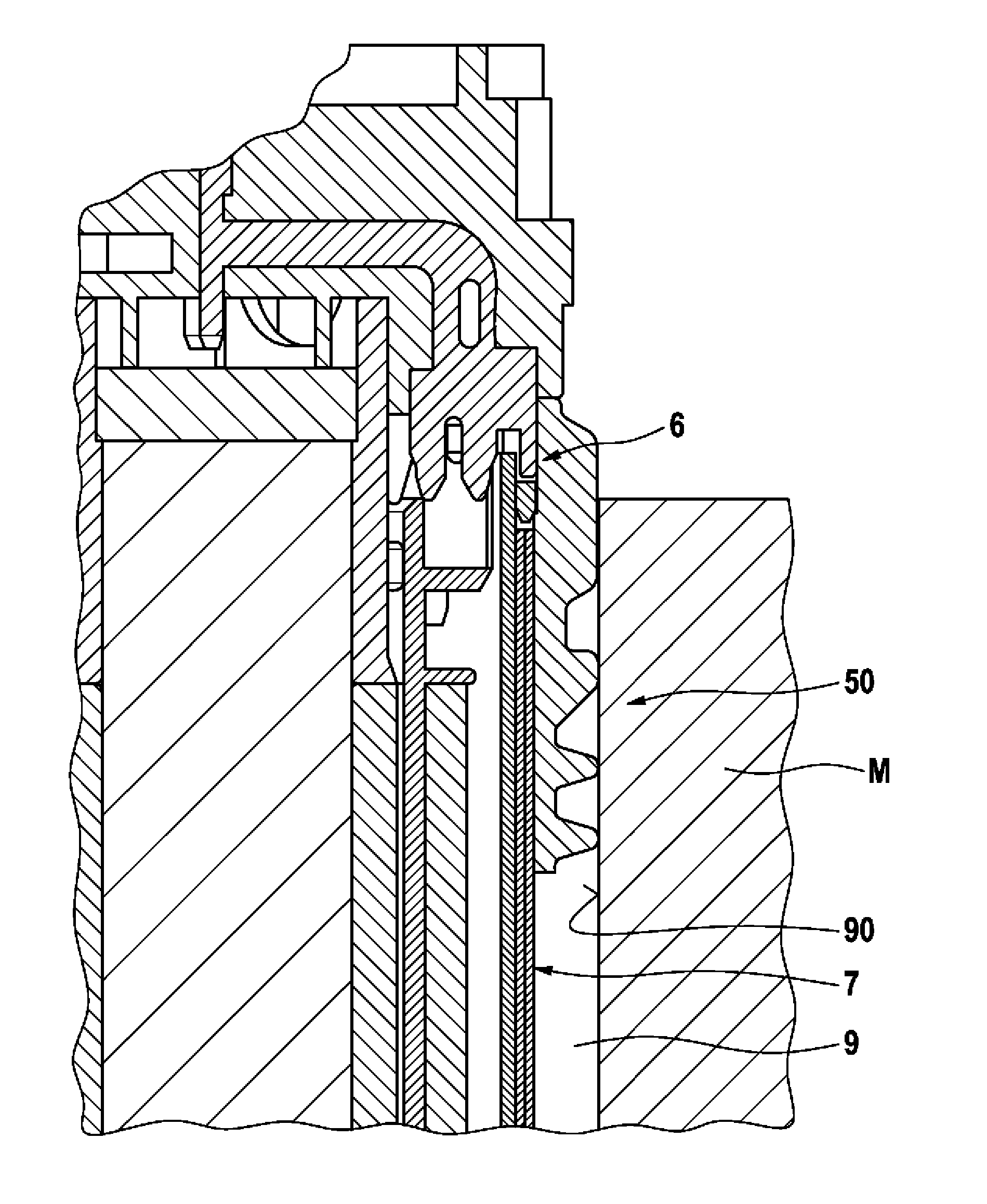

[0025] Refer below Figures 1 to 3 The ignition coil 1 and the production method based thereon are described.

[0026] exist figure 1 A section of an ignition coil 1 according to the invention is shown in , in the upper region of which a so-called ignition coil head is arranged in a housing 2 . It is used on the one hand for the electrical connection to the periphery of the ignition coil (control cable) and on the other hand for the internal electrical connection of the coil component 3 for generating the ignition spark (coil component not shown in detail). In this case, the ignition coil head includes a ground connection to the first contact region 6 , which leads to the outside. The upper edge of the connecting device 5 , which completely surrounds the housing 2 of the ignition coil 1 , is also arranged approximately on the upper edge of the first contact region 6 . The seal 50 with the sealing lip 51 connects downwards if the surface of the connecting device 5 is substan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com