Separating unit of skin, pulp and leaves of maize straw

A technology for corn stalks and separation devices, which is used in crop processors, cutters, agricultural machinery and implements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

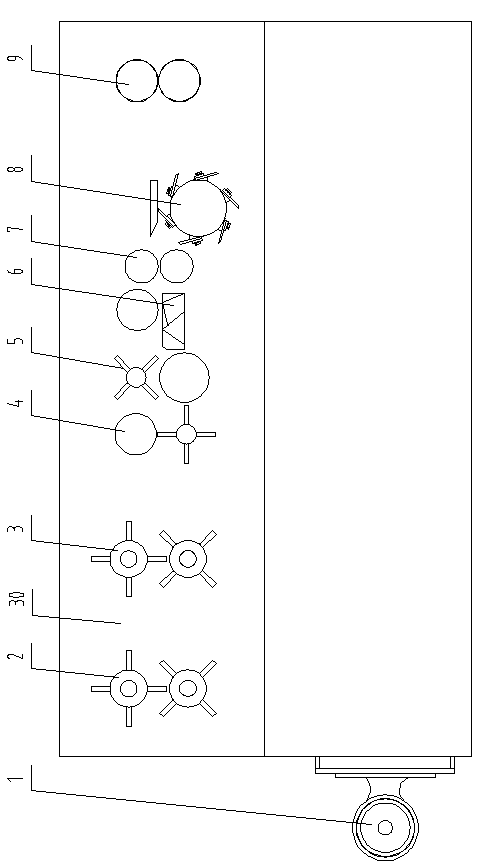

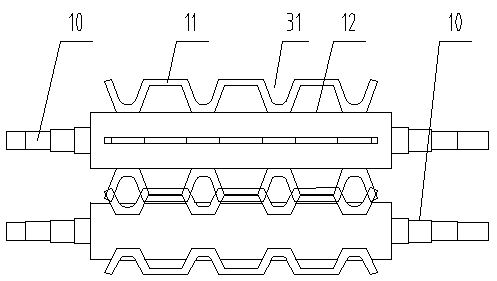

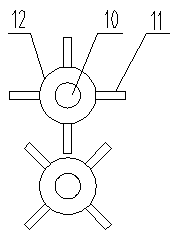

[0035] like Figure 1 to Figure 10 As shown, the corn stalk husk and pulp leaf separation device of the present invention includes a frame 30 and a power mechanism 1 arranged on the frame. Leaf removal mechanism, clamping and conveying roller assembly 4, cutting roller assembly 5, unfolding roller assembly 6, flattening roller assembly 7, peeling roller assembly 8 and outer skin output roller assembly 9, the leaf removal mechanism Including the front defoliation roller assembly 2 and the rear defoliation roller assembly 3, the front defoliation roller assembly 2 and the rear defoliation roller assembly 3 both include two defoliation shafts 10 arranged in parallel up and down, each defoliation shaft 10 The leaf removal rollers 12 are arranged in the same axial direction, and four leaf removal plates 11 are evenly arranged on the leaf removal rollers 12 in the radial direction. The leaf-removing grooves 31 on the leaf plate 11 are in a one-to-one correspondence; the leaf-removi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com