Machining technology of cam reinforcement lever mechanism

A force-increasing lever and lever mechanism technology, which is applied in the field of mechanical processing, can solve the problems that the surface finish of the arc surface cannot be guaranteed, the surface finish cannot reach the grinding process, and the processing accuracy of the heat treatment hardness layer is not accurate, etc., to solve large Insufficient batch production, improved arc surface finish, and the effect of guaranteeing the consistency of leverage ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] A processing technology of a cam booster lever mechanism, comprising the following steps:

[0034] Step 1 Rough machining

[0035] Locate the large arc and the lever arm, first rough machine the ball socket,

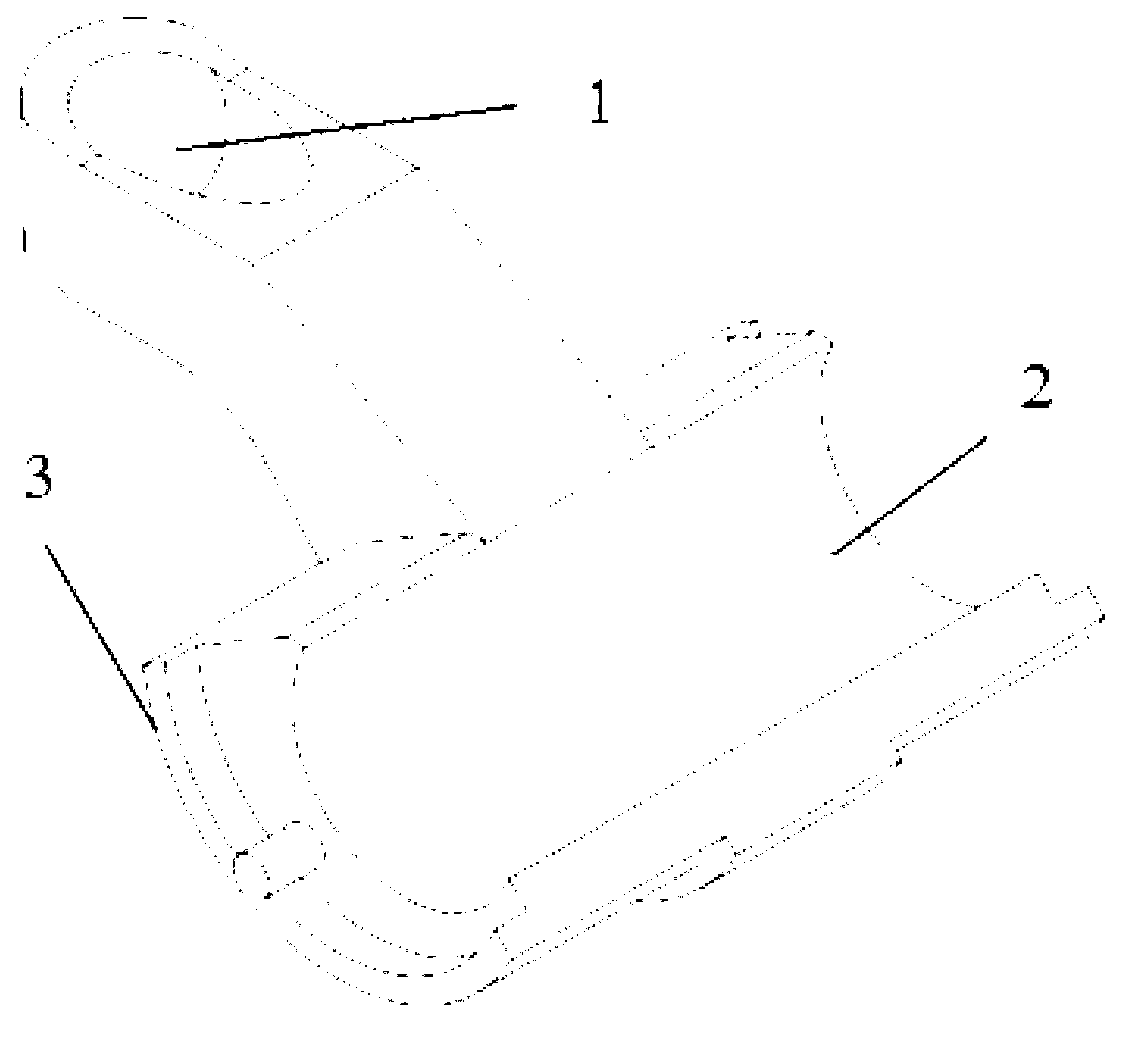

[0036] Positioning on the outer arc surface (see figure 2 ), first lock the rough-machined ball socket, then lock the lever arm, position the lever mechanism, fix the lever mechanism on the machine tool through the clamp body, rough the inner hole cylinder of the lever,

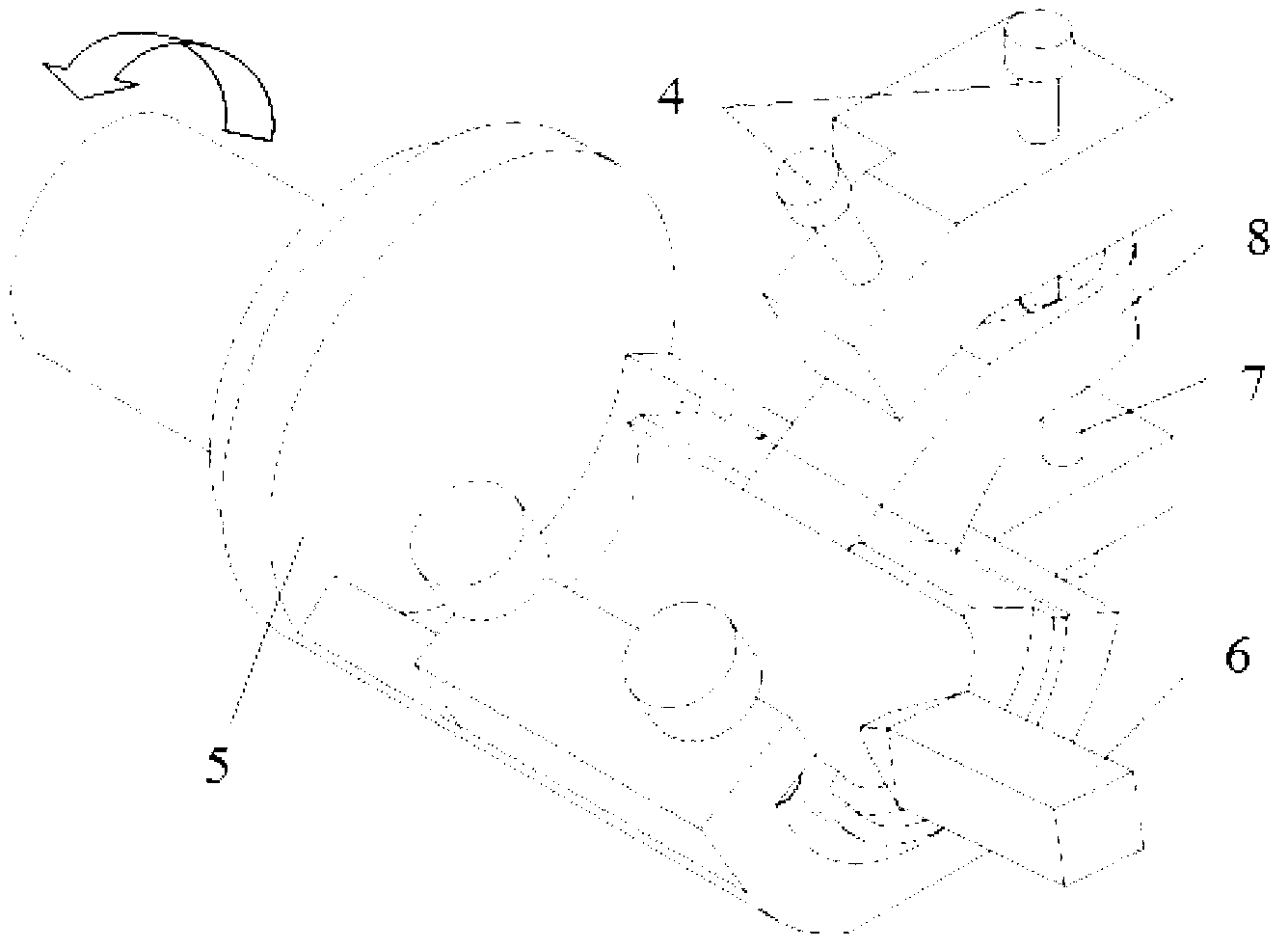

[0037] Ball and socket and circular cylindrical positioning (see image 3 ), accurately locate the lever mechanism, and then fix the lever mechanism through the pressing pin, position the inner arc surface and the lever arm, fix the lever mechanism on the machine tool through the clamp body, and rough the outer arc surface;

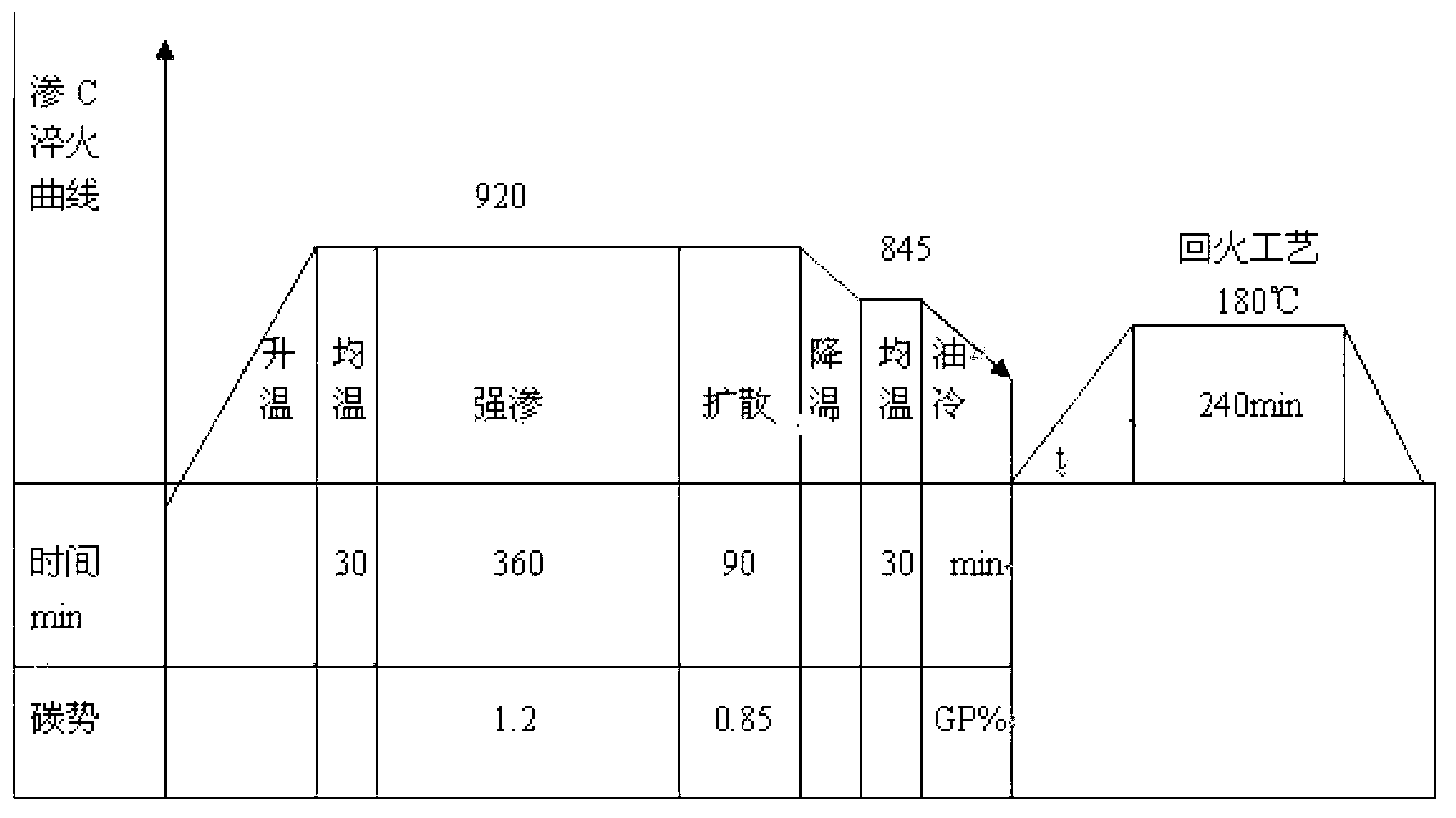

[0038] Step two heat treatment

[0039] The blank of the lever mechanism is forged from low-carbon steel. According to the function, it is necessary to increase the sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com