Dual-core two-degree-of-freedom medium-speed tin soldering robot servo controller

A servo controller and degree of freedom technology, applied in the direction of program control manipulators, manipulators, manufacturing tools, etc., can solve the problems of out-of-control soldering robots, poor anti-interference ability, complex control circuits, etc., achieving a high degree of automation and high work efficiency , control the precise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

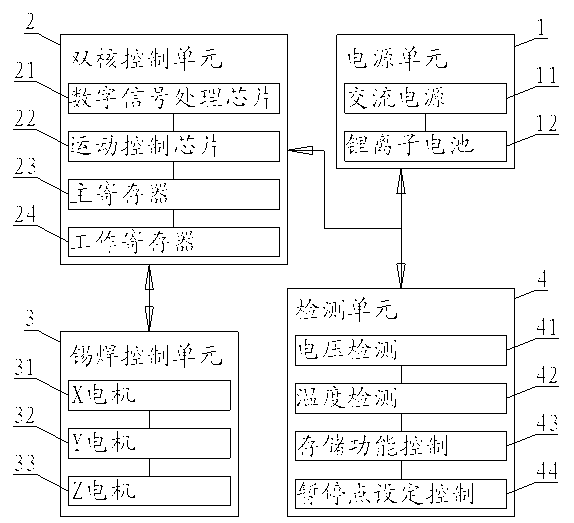

[0015] see figure 1 , a dual-core two-degree-of-freedom medium-speed soldering robot servo controller, including: a power supply unit 1, a dual-core control unit 2 and a soldering control unit 3, the power supply unit 1 includes an AC power supply 11 and a battery, and the dual-core control unit 2 includes a connected digital signal processing chip 21 and a motion control chip 22. The soldering control unit 3 includes a motion control motor and a tin output control motor. The motion control motor is used to control the soldering head on a two-dimensional plane. The X motor 31 and the Y motor 32 moving up, the tin output control motor is a Z motor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com