A kind of preparation method of yag:sm3+,bi3+ fluorescent glass

A technology of fluorescent glass and precursor, applied in the field of preparation of YAG:Sm3+, Bi3+ fluorescent glass, can solve the problems of lack of red light, shortened service life, high color temperature, and achieve the effect of improving light color quality and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

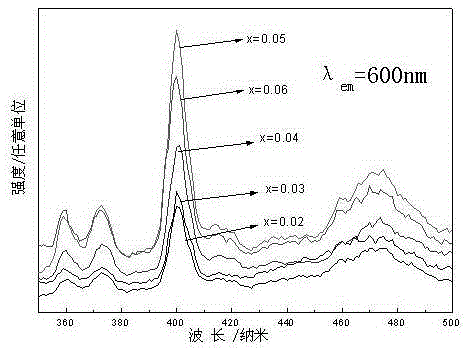

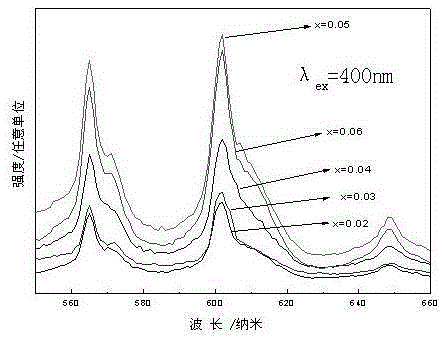

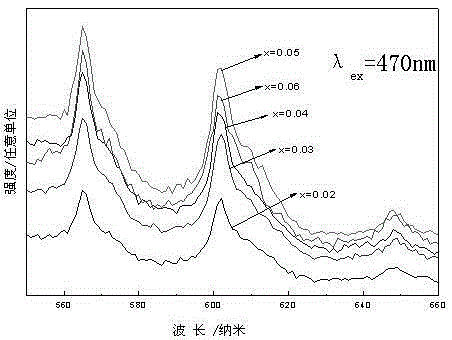

Image

Examples

Embodiment Construction

[0035] A YAG:Sm 3+ , Bi 3+ The preparation method of fluorescent glass comprises the following steps:

[0036] (1) Preparation of precursor:

[0037] Prepare yttrium nitrate, samarium nitrate, bismuth nitrate, and aluminum nitrate solutions with a concentration of 0.2mol / L, according to the stoichiometric ratio Y:Sm:Bi:Al=2.95-y:0.05:y:10, that is, 29.5-10 μmL of yttrium nitrate, Samarium nitrate 0.5mL, bismuth nitrate 10μmL, aluminum nitrate 100mL, y=0, 0.02, 0.04, 0.06, 0.08, add the metal ion solution into the mixed precipitant at a constant temperature of 25°C at a constant flow rate of 3mL / min with a separatory funnel, Stir continuously, adjust the pH to 6.5 with ammonia water during the dropwise addition, continue to stir for 2 hours after the dropwise addition, stop stirring, age for 12 hours, pour off the supernatant, and after the precipitation is centrifuged, wash the precipitation precursor twice with deionized water 1. Wash with ethanol twice to remove water and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com