Preparation method for heat insulation wall paint

A technology of thermal insulation and production method, which is applied in the direction of reflection/signal paint, coating, etc., and can solve the problems of large safety hazards, complex construction of external thermal insulation technology for external walls, and poor environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

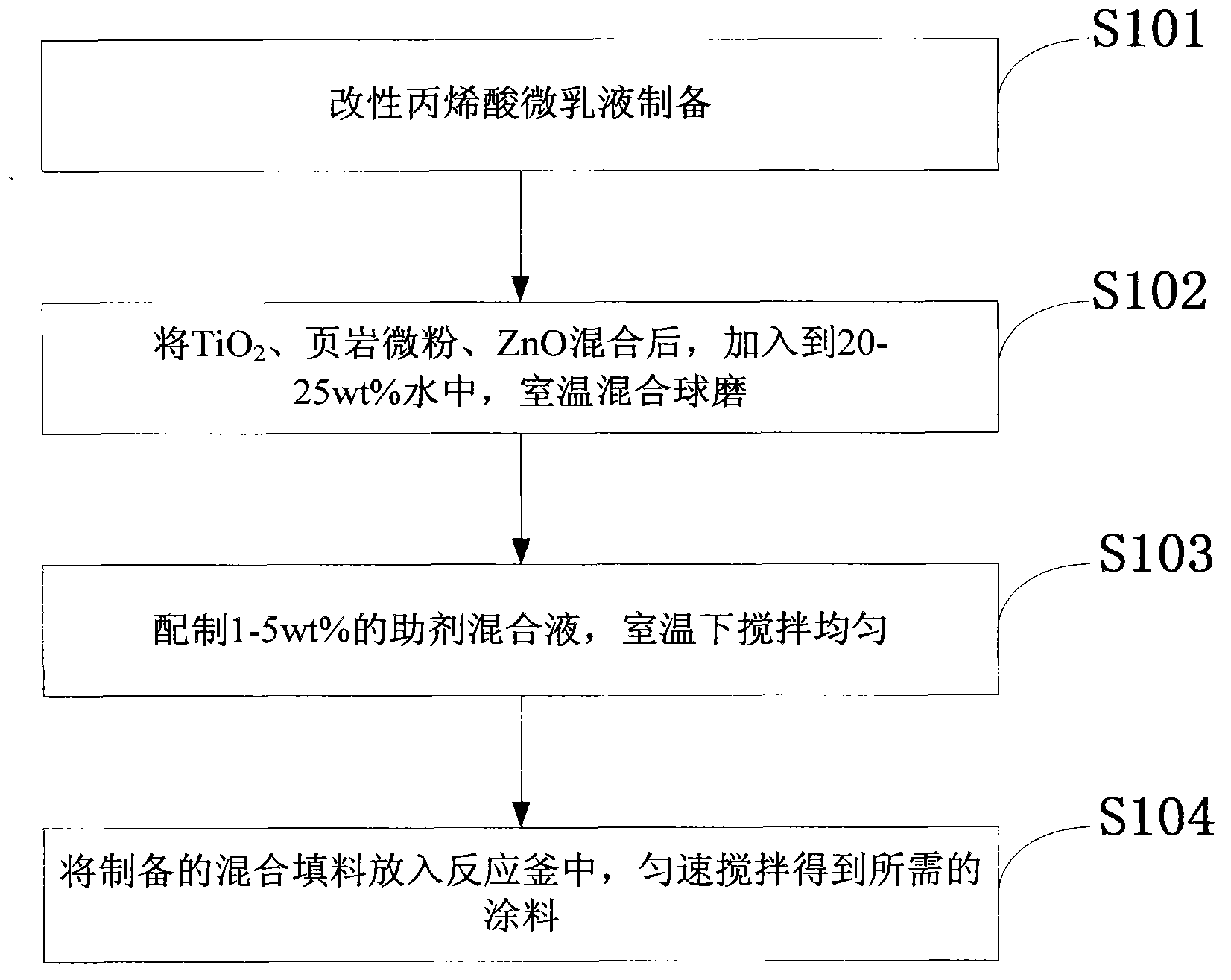

Method used

Image

Examples

specific Embodiment

[0063] Implementation site: Hunan Jiafule Energy Saving Technology Co., Ltd.

[0064] Mix acrylate, styrene, and acrylic acid in a weight ratio of 25:25:1.5, and add to the weight ratio of water, emulsifier OP-10, and surfactant sodium dodecylbenzenesulfonate in a ratio of 150:0.69:0.69. In the prepared emulsion, stir evenly at 60-70°C, then add 0.1% initiator potassium persulfate relative to the weight of styrene, and react until the milky white viscous product appears in the mixed solution, and the reaction time is usually 2 ~ 3 hours (the specific time depends on the amount of reactants), and finally adjust the pH value of the product to 7 ~ 8 with a weak base (NaOH) to prepare a modified acrylic microemulsion;

[0065] 5wt% TiO 2 , 2wt% shale fine powder and 5wt% ZnO are mixed, then added to 20-25wt% water, mixed and ball milled at room temperature for 12 hours;

[0066] Prepare 1-5wt% additive mixture and stir evenly at room temperature;

[0067] Put the prepared mixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com