Paper protection method for sealing, protecting and reinforcing through high voltage electrostatic spinning film coating

A high-voltage electrospinning and paper technology, which is applied in the post-processing of waste paper, can solve the problems of no paper material application reports, inability to promote large-scale use, and accelerate paper aging, so as to achieve easy-to-obtain reinforcement materials and adjustable pore size Control and equipment are simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

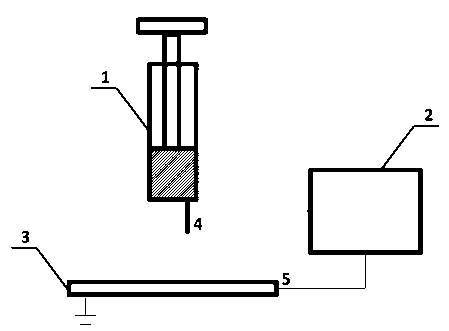

Image

Examples

Embodiment 1

[0028] Take the newspaper from the 1970s for spinning and sealing, add 12g PVDF to 100ml DMF and mix it evenly as the spinning solution. The flow rate is 0.7 ml / h, the voltage is 15kV, and the spinning film thickness is 300. . Observe the onlooker morphology of the newspaper after spinning reinforcement, such as figure 2 Shown. It can be seen that the polymer fibers are evenly distributed, and the pore radius on the surface of the mesh fiber membrane is about 1 about.

Embodiment 2

[0030] Take Anhui Red Star rice paper for spinning and sealing, add 20g PVP into 100ml ethanol and mix it evenly as the spinning solution. The flow rate is 0.5 ml / h, the voltage is 20kV, and the spinning film thickness is 50. . The tensile strength of the paper before treatment is 0.824 kN / m, and the tensile strength of the paper after treatment is 0.953 kN / m.

Embodiment 3

[0032] Take the newspaper from the 1970s for spinning and sealing, add 15g PVDF to 100ml DMF and mix it as the spinning solution, the flow rate is 1.0 ml / h, the voltage is 25kV, and the spinning film thickness is 100 . The water contact angle of the paper before the measurement was 42°, and the contact angle increased to 148° after the treatment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com