Method for manufacturing badminton racket

A badminton racket and a manufacturing method technology, applied in the field of badminton racket manufacturing, can solve problems such as difficulty in upgrading, undiscovered and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

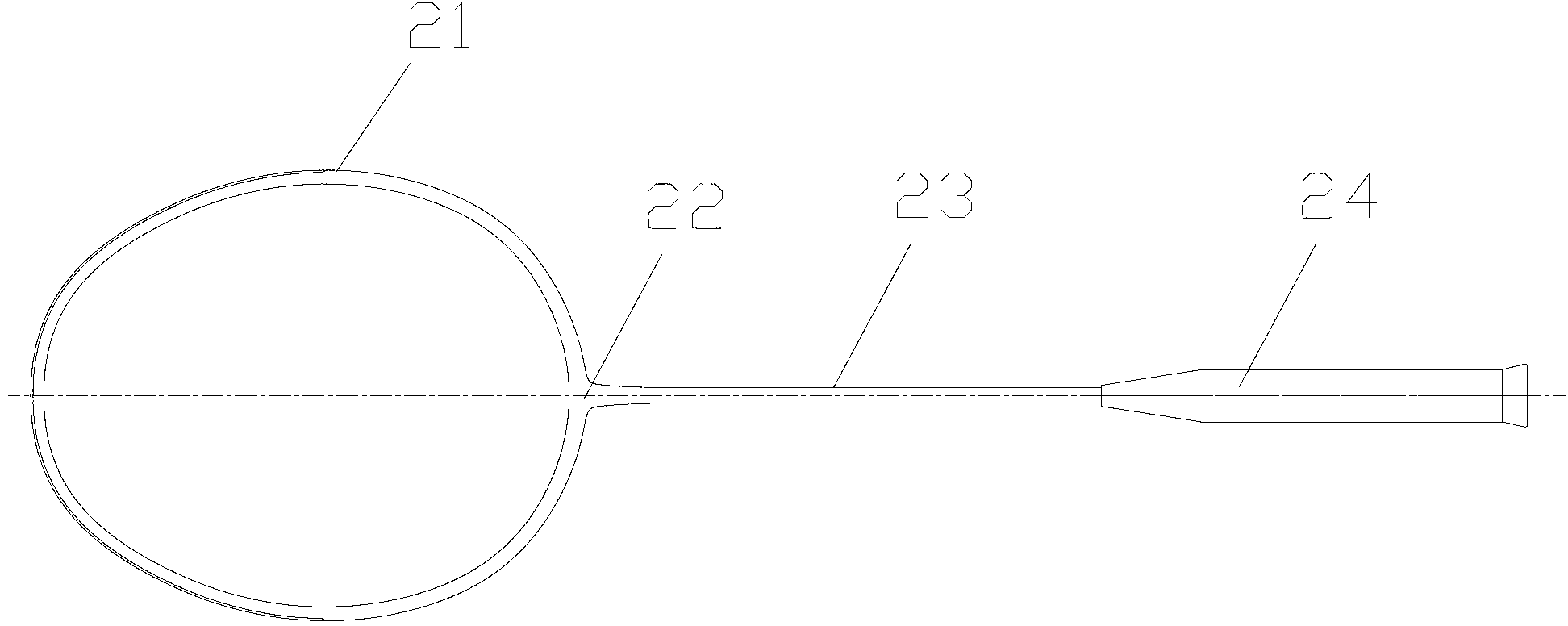

[0030] The basic structure of the racket is as follows: figure 1 As shown, it is composed of a racket frame 21, a T-shaped connector 22, a middle pipe 23, and a handle 24.

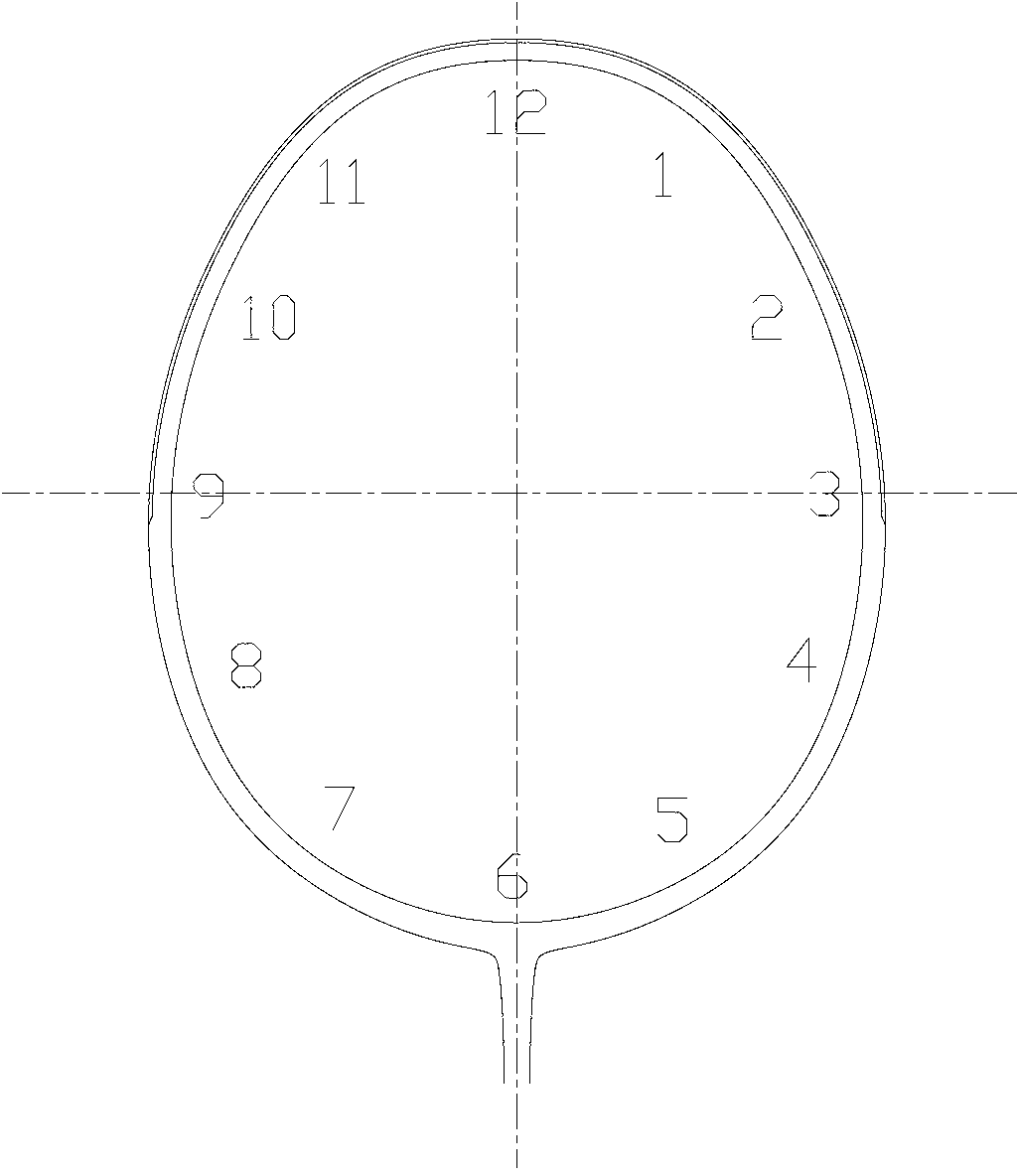

[0031] For ease of understanding, figure 2 The schematic diagram of the racket frame in this embodiment includes a common clock dial, where the twelve o’clock position (12) is located at the top of the racket frame 21 away from the racket handle 24, and the six o’clock position (6) is located at the position where the T-shaped connector 22 is located .

[0032] The manufacturing method of the badminton racket of this embodiment comprises the following steps:

[0033] The first step is to make different foam materials into foam preforms respectively;

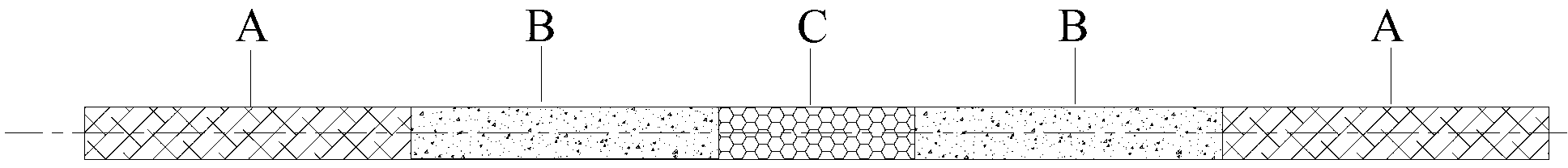

[0034] The foaming material used can be epoxy resin, EVA, polyurethane, polyester and other resins, or rubber such as styrene-butadiene rubber and nitrile rubber, or fiber reinforced materials.

[0035] The second step is to cut each foam prefabricated b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic modulus | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com