Liquid distribution and redistribution device for multistage rotating rectification bed

A technology of liquid distributor and liquid distribution, which is applied in the direction of fractionation and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

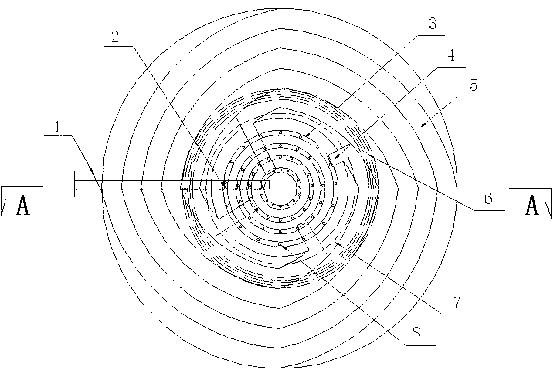

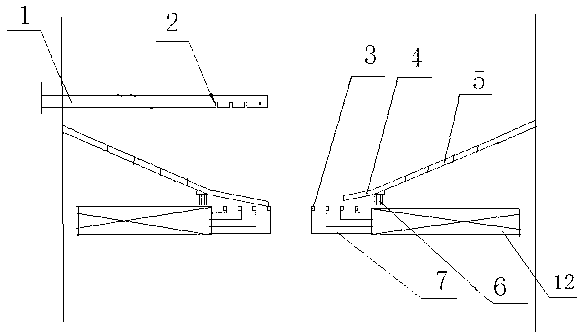

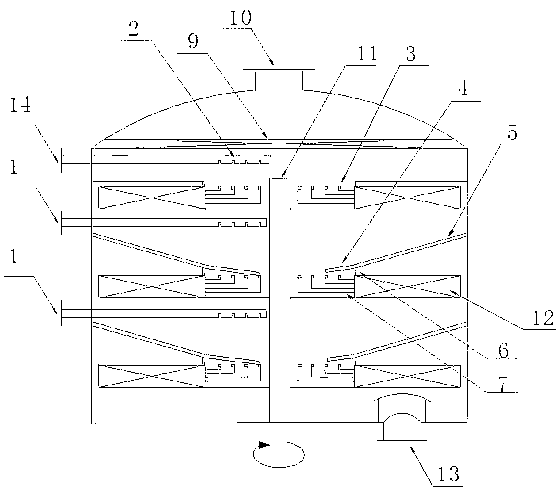

[0023] There are 4 liquid distribution grooves 2 on the front end of the inlet pipe 1, 4 spiral grooves 5 on the cone -shaped liquid and distributer 4, and the U -shaped flat -rotating liquid distributor 7 structure includes a flat disk, a flat plate ringThere are U -shaped split grooves 3 on the inner wall of the shape, the bottom of the U -shaped split groove is equipped with a cloth liquid hole 8, the U -shaped flat plate rotating liquid distributor 7 is 4, and it is concentric.Large, from bottom to top arrangement settings.

[0024] The position of the 4 liquid distribution groove 2 is corresponding to the position of the 4 U -shaped flat plate rotating liquid distributor 7.The outer side of the liquid and distributer 4 is connected with the cylindrical of the cylinder of the rotating filler.There is a maze -type seal 6 in the lower side of the cone -shaped liquid and distributer 4.

[0025] In this way, there are 4 long cloth grooves 2 drooping in the horizontal liquid pipe 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com