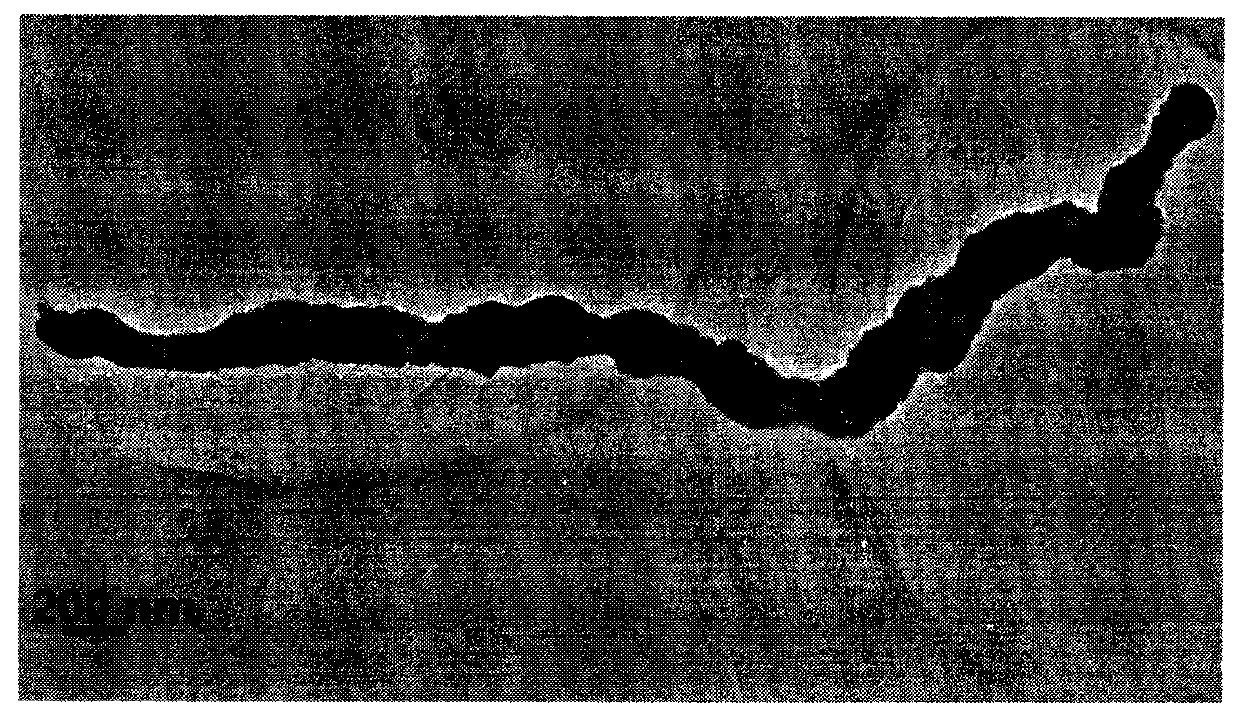

Method for preparing mass wormlike palladium nanotubes

A worm-like, palladium nanotechnology, applied in the field of preparation of large quantities of worm-like palladium nanotubes, to achieve the effect of high catalytic activity and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in conjunction with specific embodiments.

[0015] 1.1. Drugs

[0016] Palladium Chloride (PdCl 2 ), dimethylglyoxime (dmg), ethylene glycol, ascorbic acid and NaBH4 were purchased from Aladdin Ltd. All reagents were of analytical grade and used without further purification. All aqueous solutions were prepared with double distilled water.

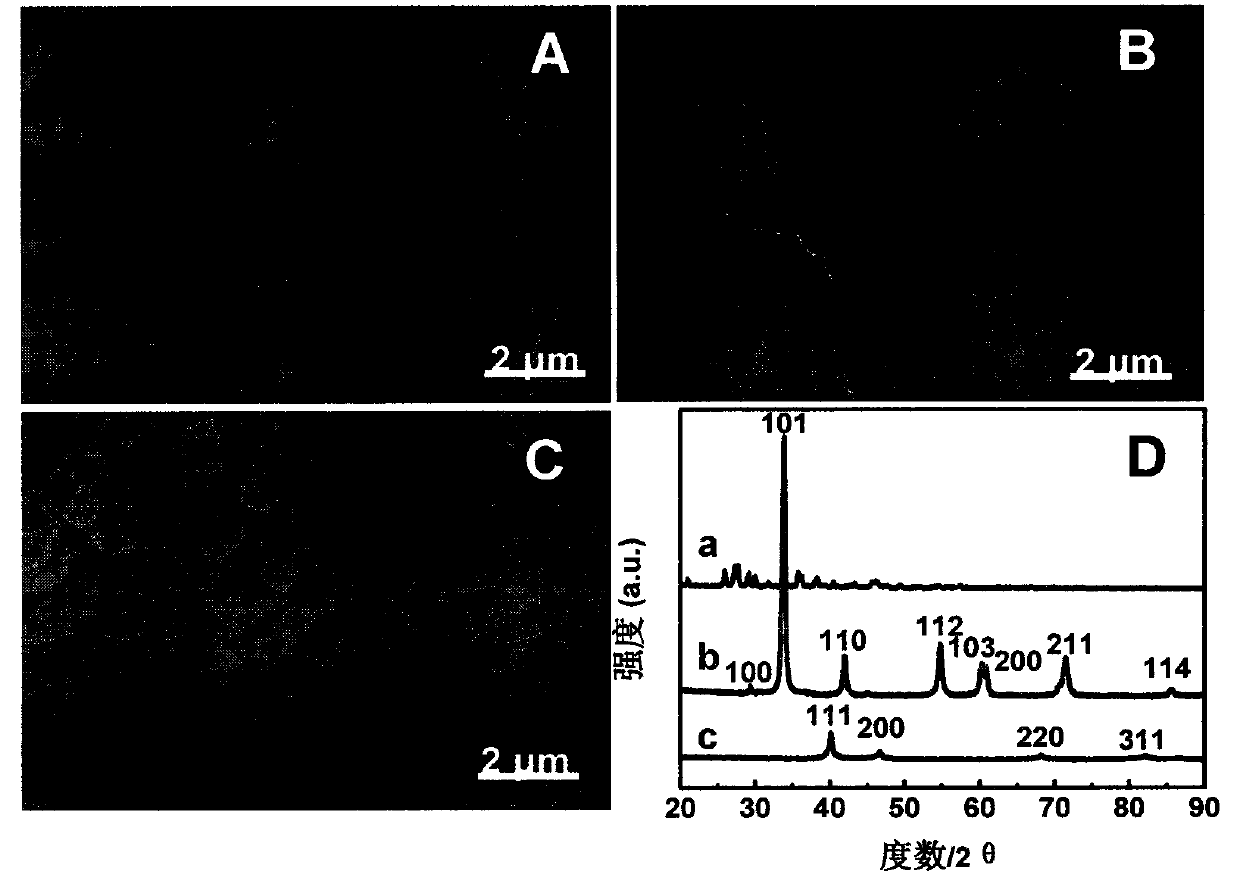

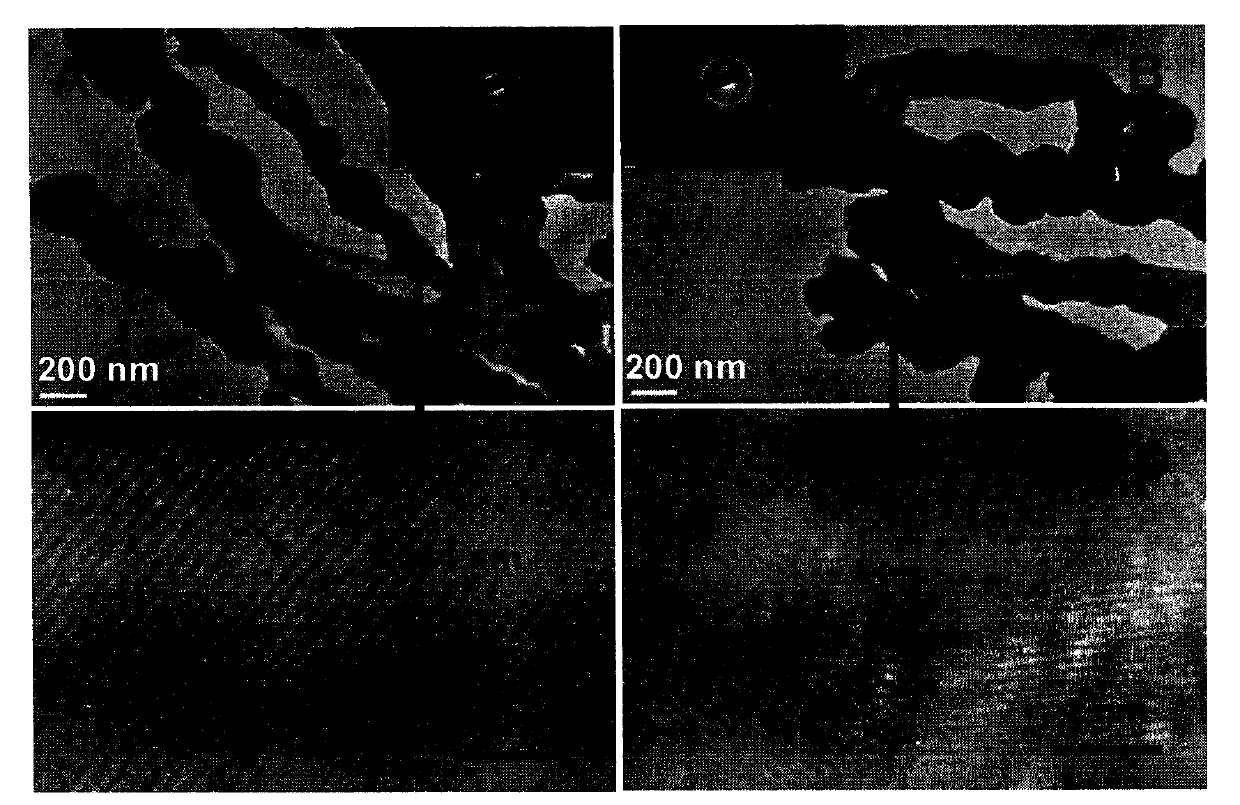

[0017] 1.2. Synthesis of PdO WNTs

[0018] Put 10mL PdCl 2 Solution (100mM) was added dropwise to 25mL dimethylglyoxime solution (37mM) while stirring (PdCl 2 and dimethylglyoxime molar ratio is about 1:1-2). The resulting precipitate was thoroughly washed with water by centrifugation, dried at 60°C, calcined in a muffle furnace at 450°C for 2 hours, and cooled naturally to room temperature for later use.

[0019] 1.3. Synthesis of PdWNTs

[0020] 0.02g PdO WNTs with 10mL NaBH 4 The solutions (25mM) were mixed and stirred for 2h. The finally obtained black precipitate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com