Deactivated catalyst regeneration and density grading system and process thereof

A technology for deactivating catalysts and density classification, which is applied in catalyst regeneration/reactivation, physical/chemical process catalysts, chemical instruments and methods, etc., and can solve the problem of inability to remove heavy metal impurities at the same time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

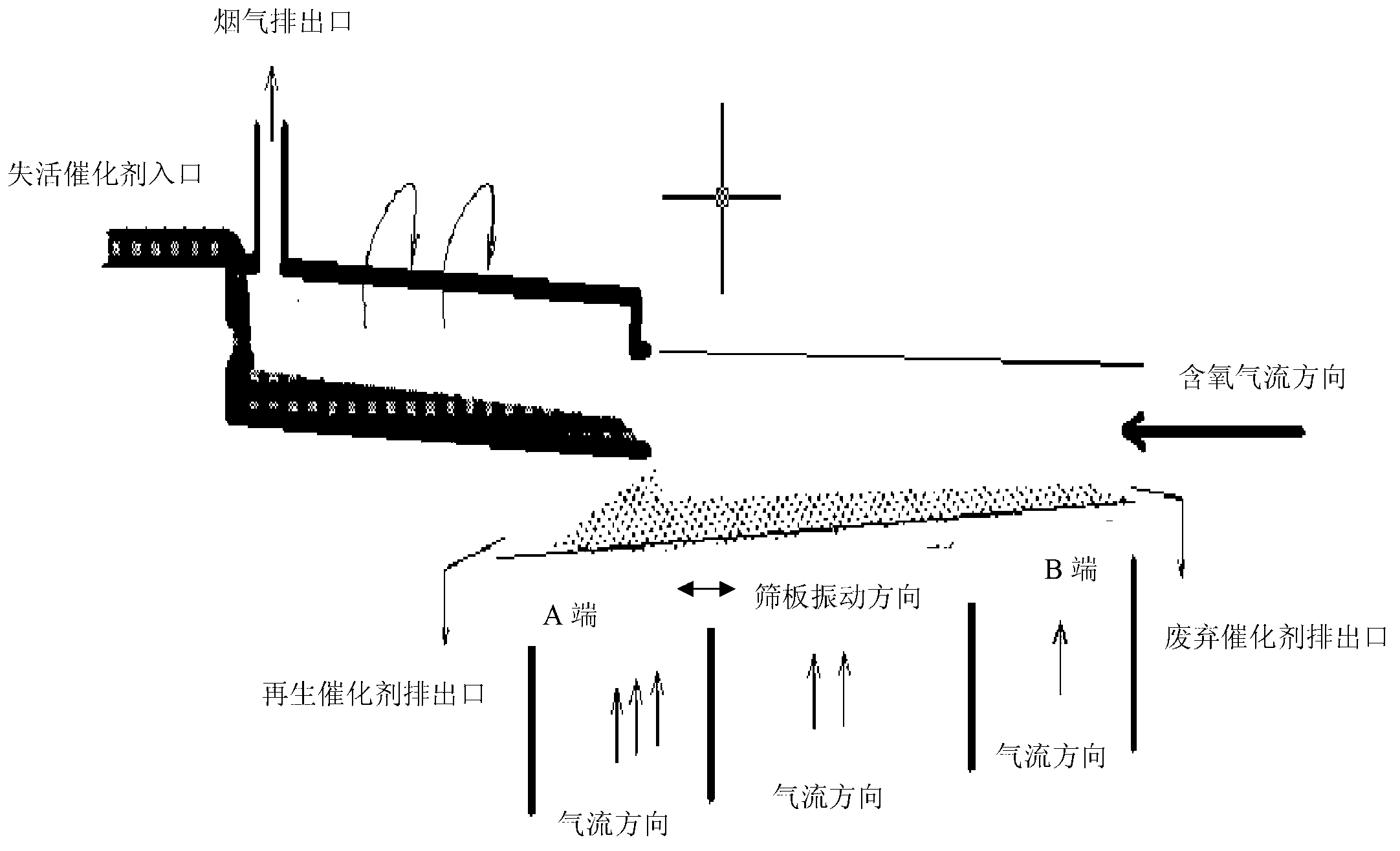

[0060] according to figure 1 The process shown is to regenerate and classify the deactivated catalyst after deoiling.

[0061] After the above-mentioned deoiled deactivated catalyst particles are screened with a sieve, they are sent to the rotary kiln for desulfurization and carbon removal regeneration through a hopper. With the rotation of the rotary kiln, the deactivated catalyst is spread on the surface On the inner surface, the thickness of the catalyst is maintained between 0.5-1.0 cm when the rotary kiln rotates, and the process air (oxygen-containing flow) is reversely passed into the rotary kiln, and the process air / catalyst volume in which the desulfurization and carbon removal reactions occur in the rotary kiln The ratio (air / agent ratio) was 4000 / hour, and the oxygen content in the process air was 21% by volume.

[0062] Control the temperature rise of the rotary kiln within 10°C / min to carry out the slow regenerative coking process. The final coking temperature (m...

Embodiment 2

[0069] The procedure of Example 1 was repeated under the same conditions as in Example 1 except for adjusting the following operating conditions of the vibrating sieve.

[0070] Change the inclination angle of the sieve plate from 5° to 3°; change the opening ratio of the sieve plate from 40% to 35%; change the vibration frequency from 80 times / min to 90 times / min; change the amplitude from 2 mm to 3 mm.

[0071] Likewise, the above-mentioned low-density catalyst particles collected or discharged from the lower end (A end) of the sieve plate are used as regenerated catalyst to be recycled, which is marked as regenerated catalyst C.

[0072] The properties of the above-mentioned regenerated catalyst C to be recycled are shown in Table 3, the process conditions for evaluating the catalytic activity of its hydrofining reaction are shown in Table 4, and the performance data of the crude oil directly liquefied from coal produced by using it are shown in Table 5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com