System and method for air classification of iron core powder particle size

A wind classification, iron ore technology, applied in chemical instruments and methods, solid separation, separation of solids from solids with air flow, etc., can solve the problems of inability to deal with accurate classification, reduce the chance of entering the kiln, improve Production efficiency, solve the effect of easy looping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

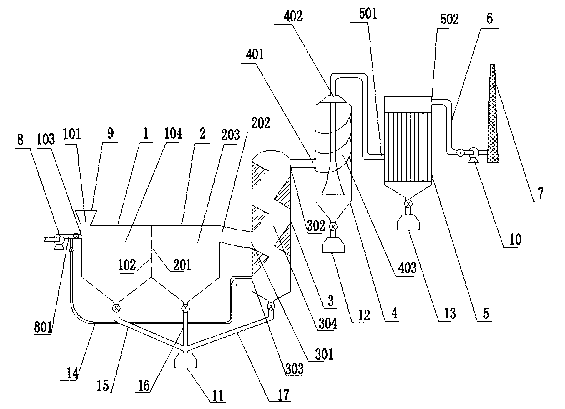

[0027] Such as figure 1 As shown, a wind power classification system for iron ore powder particle size includes a blower 8, a primary horizontal wind separator 1, a secondary horizontal wind separator 2, a vertical wind separator 3, a cyclone wind separator 4, a bag collector 5, The first silo 11, the second silo 12, the third silo 13 and the air outlet 7; the first-level air separator 1 includes a feed port 101 and the discharge port 102; the second-level air separator 2 includes an inlet Feed port 201, discharge port 202, vertical air separator 3 includes feed port 301, discharge port 302; cyclone wind separator 4 includes feed port 401, discharge port 402; cloth bag collector 5 includes feed port 501 and air outlet 502;

[0028] The feed inlet 101 of the primary horizontal air separator 1 is connected to the hopper 9, and the discharge port 102 is connected to the feed inlet 201 of the secondary horizontal air separator 2. One side of the feed inlet 101 of the primary hori...

Embodiment 2

[0037] The iron ore powder particle size wind classification system of this embodiment is the same as that of Embodiment 1.

[0038] The method of using the above-mentioned grading system in this embodiment to carry out 0-5mm particle size iron ore powder particle size wind classification is to use the iron ore powder with a particle size of 0-5mm and a water content of less than 6% from the hopper and the first-level horizontal wind separator 1 The feed port 101 of the feeder is evenly fed into the primary horizontal air separator 1, and air is used as the air separation medium. Under the action of the blower 8, the iron ore powder passes through the primary horizontal air separator 1 and the secondary horizontal air separator in sequence. 2. The vertical air separator 3, the cyclone air separator 4 and the bag collector 5 carry out particle size classification; during the classification process, the wind pressure of the air outlet 801 of the blower 8 is controlled to 18Kpa, a...

Embodiment 3

[0041] The iron ore powder particle size wind classification system of this embodiment is the same as that of Embodiment 1.

[0042] The method of using the above-mentioned grading system in this embodiment to classify iron ore powder with a particle size of 0-5mm and a water content of less than 6% by wind power classification is to use the hopper and the first-level horizontal air separator The feed port 101 of 1 is evenly fed into the first-level horizontal air separator 1, and the rotary kiln flue gas is used as the air-selection medium. Under the action of the blower 8, the iron ore powder passes through the first-level horizontal air separator 1 and the second-level air separator in turn. The horizontal wind separator 2, the vertical wind separator 3, the cyclone wind separator 4 and the bag collector 5 carry out particle size classification; during the classification process, the air pressure of the air outlet 801 of the blower 8 is controlled to be 20Kpa, and the solid-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com