Automatic fermented grain material discharge device

A technology of fermented grains and cellar pools, which is applied in the field of solid-state fermentation wine brewing equipment, can solve the problems of large amount of manual assistance, easy to damage the cellar wall, and low cellar output rate, so as to reduce labor intensity, protect the cellar wall, The effect of high net rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

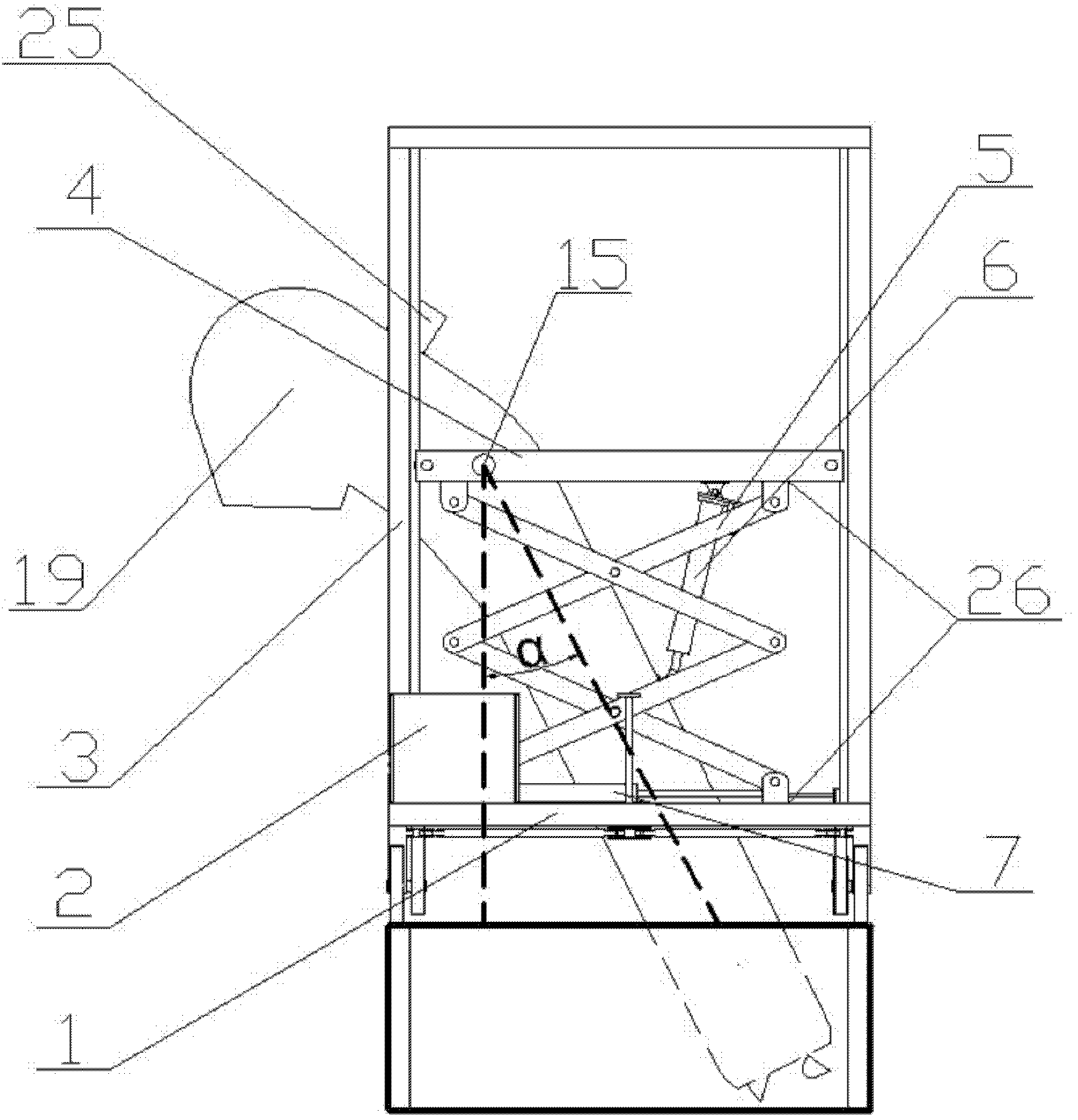

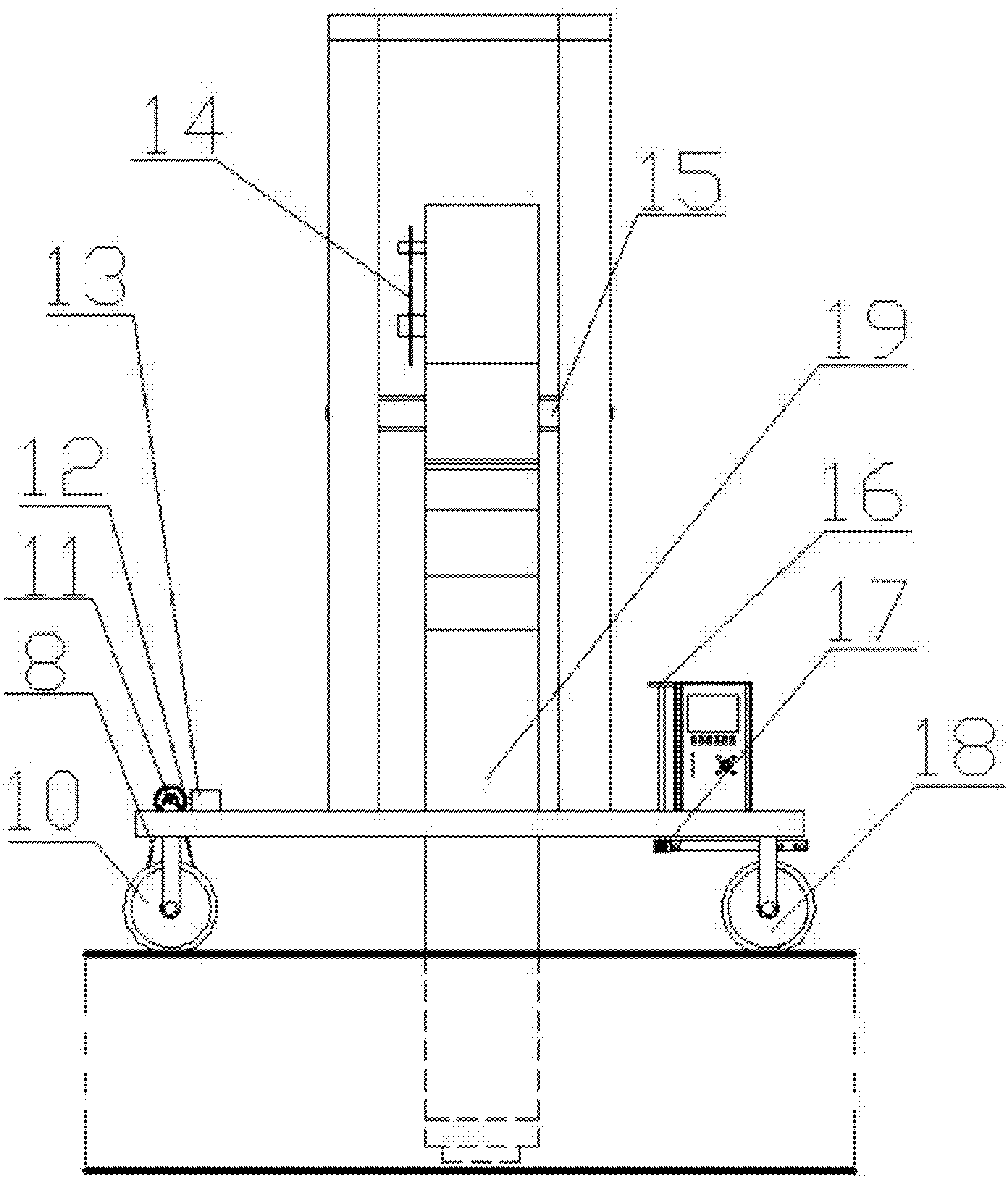

[0020] figure 1 It shows the main schematic diagram of the structure of the wine cellar unloading device for fermented grains proposed by the present invention; figure 2 A schematic side view of the structure of the wine cellar unloading device for fermented grains proposed by the present invention is shown. see figure 1 with figure 2 , the wine cellar unloading device includes:

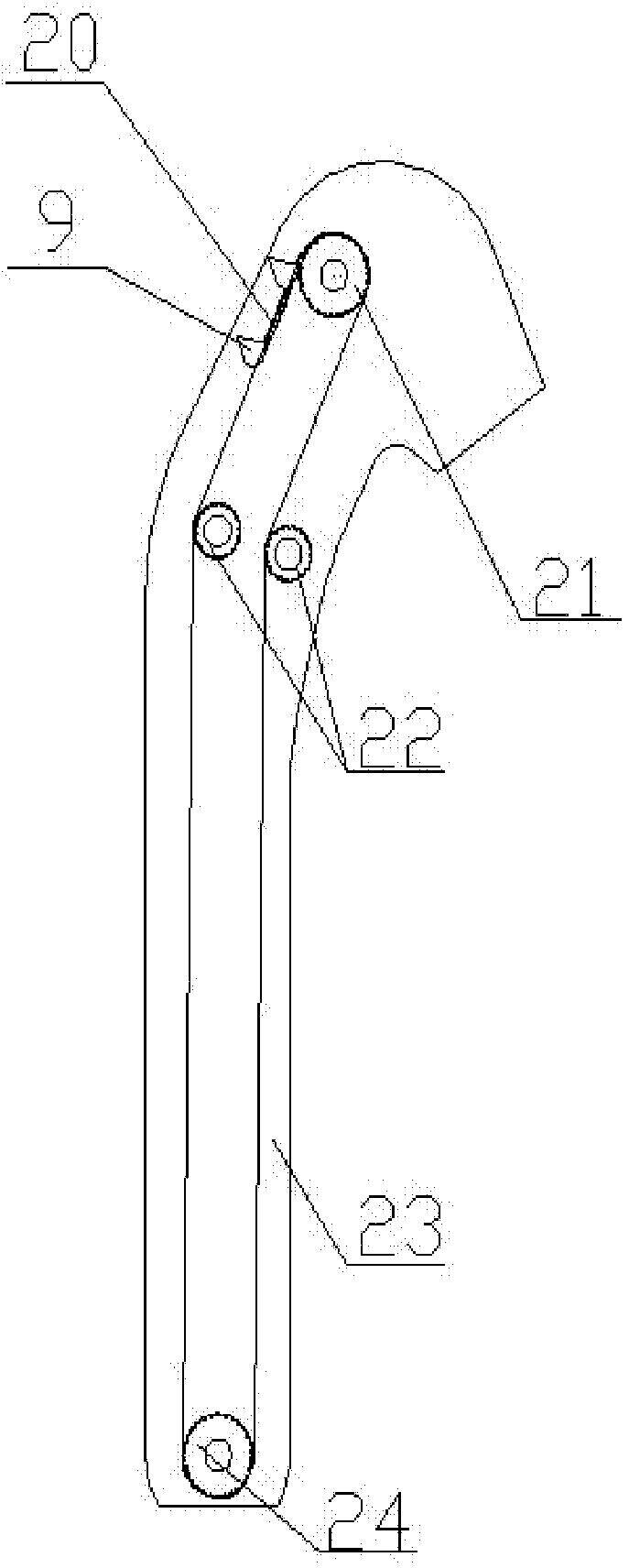

[0021] Bucket-type lifting main body, which specially adopts a corner structure that is helpful for loading and unloading wine grains, and is suspended on the upper end of the scissor lifting mechanism through its own main rotating shaft, and its waist is passed through the swing linear electric cylinder and the load-bearing in the scissor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com