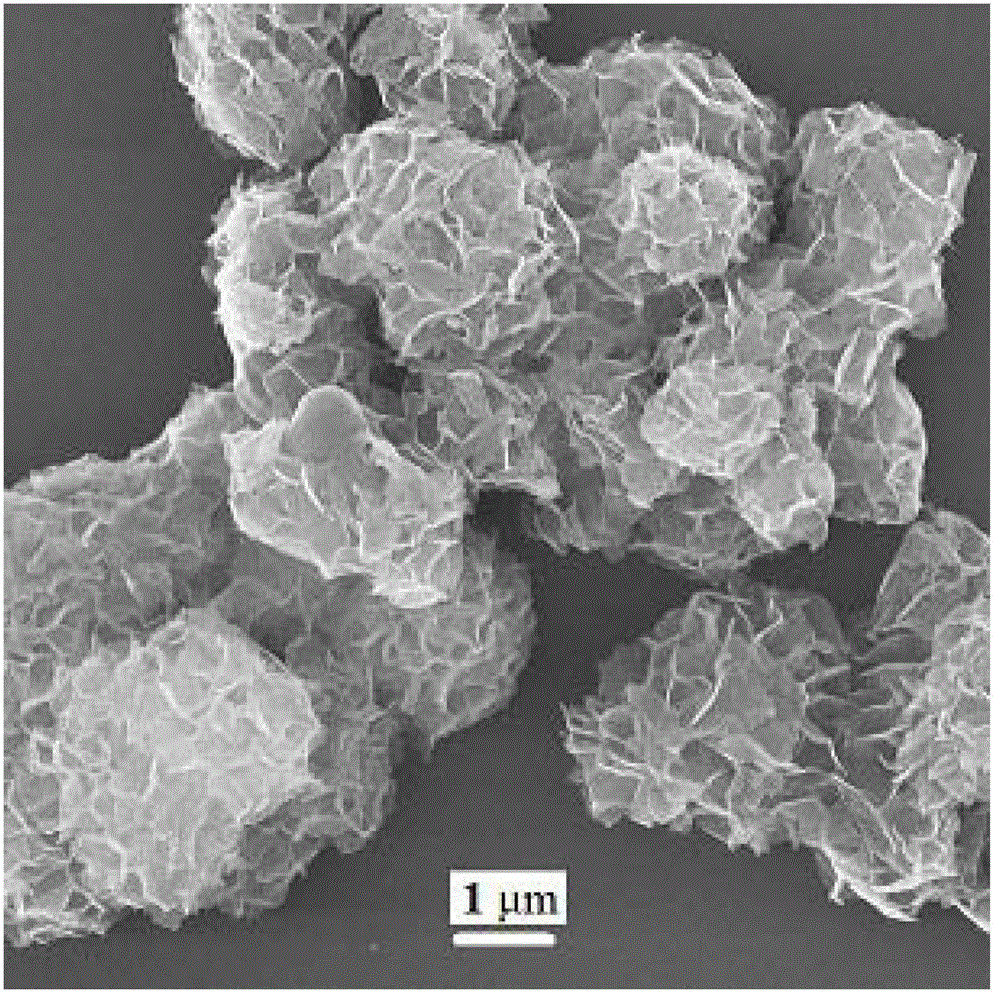

Three-dimensional flower-like layered double hydroxide and preparation method thereof

A layered compound and hydroxide technology, applied in the direction of aluminum oxide/aluminum hydroxide, zinc oxide/zinc hydroxide, nickel oxide/nickel hydroxide, etc., can solve the inconvenience of industrial production, high production cost, environmental hazards, etc. problem, achieve the effect of low cost and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Step A: Weigh 10g of aluminum sulfate and add it to 190g of deionized water to prepare an aluminum sulfate solution, weigh 36g of urea, add it to the aluminum sulfate solution and mix well. Under vigorous stirring, adjust the pH value of the aluminum solution to 3.85 with a mass fraction of 2.5% ammonia solution, and then place the aluminum solution in a water bath at 98°C for a heating reaction for 30 minutes, so that the aluminum ions in the aluminum solution rapidly form an amorphous form. Aluminum hydroxide is precipitated, and the precipitate is centrifuged and washed to prepare an aluminum hydroxide slurry with a mass fraction of 5%.

[0026] Step B: Weigh 1.2g MgSO 4 Add it into 20 g of deionized water to prepare a solution, then add it into 7.8 g of the above-mentioned aluminum hydroxide slurry, and mix well.

[0027] Step C: Weigh 6g of urea and 0.08g of NaOH and add it to 80g of deionized water to prepare an alkali solution. Add the alkali solution directly t...

Embodiment 2

[0029] Step A is the same as in Example 1.

[0030] Step B: take by weighing 3.84g Mg(NO 3 ) 2 ·6H 2 O was added to 20 g of deionized water to prepare a solution, then added to 7.8 g of aluminum hydroxide slurry, and mixed evenly.

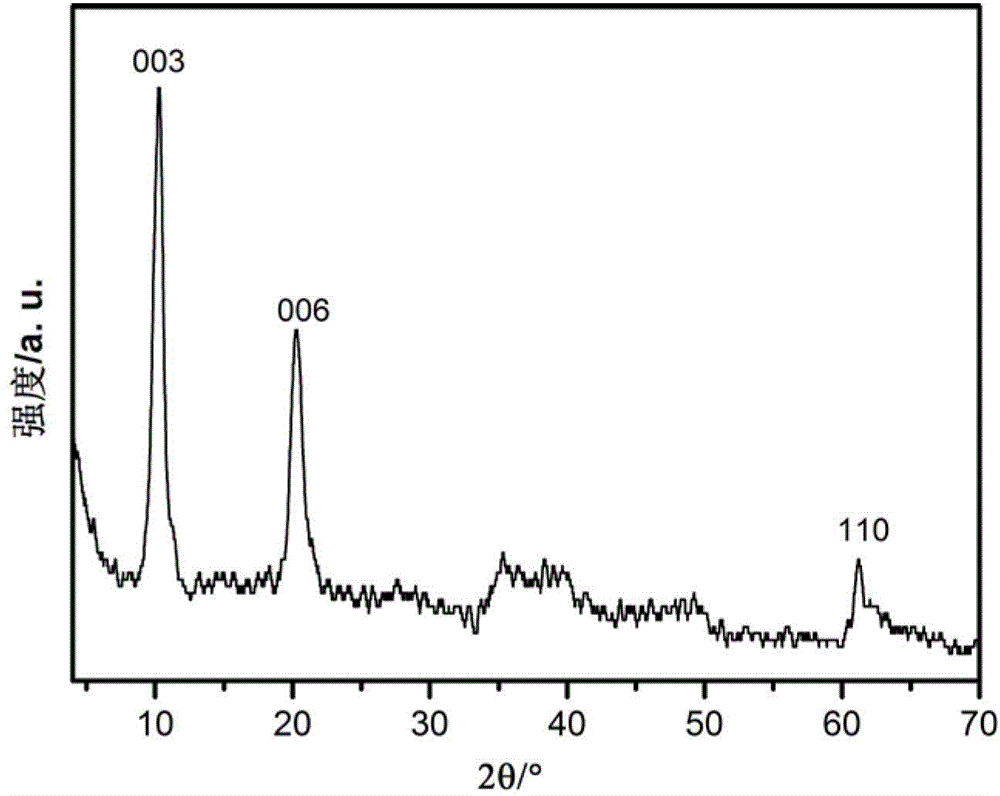

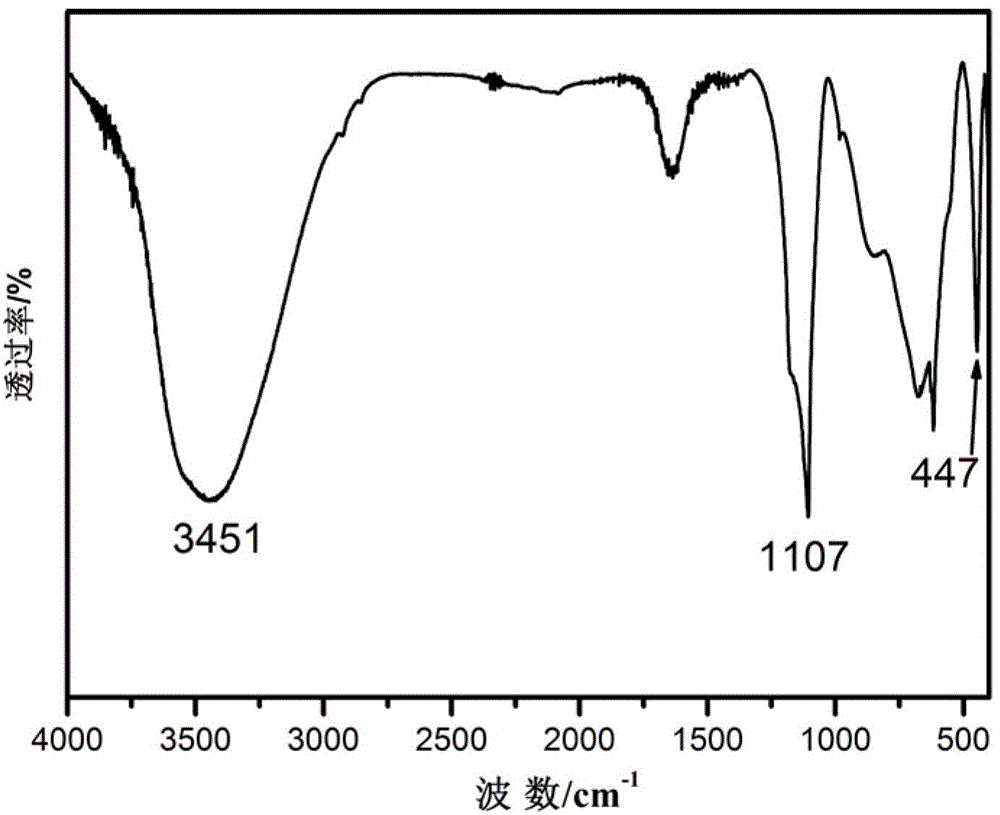

[0031] Step C: Weigh 6g urea and 0.53g Na 2 CO 3 Add it into 80g of deionized water to prepare an alkaline solution, and directly add the alkaline solution to the slurry prepared in step B at 95°C under stirring, then continue the reaction at 98°C for 9 hours, and cool the slurry to room temperature after the reaction. The precipitate was washed by centrifugation until the pH value was less than 8, and the sample was dried in an oven at 100°C for 12 hours to obtain a three-dimensional flower-like LDH product. Elemental analysis shows that the chemical composition formula of the product is: Mg 0.75 Al 0.25 (OH) 2 (CO 3 ) 0.125 0.65H 2 O, BET analysis shows that its specific surface area is 183m 2 / g.

Embodiment 3

[0033] Step A is the same as in Example 1.

[0034] Step B: take by weighing 5.12g Mg(NO 3 ) 2 ·6H 2 O was added to 20 g of deionized water to prepare a solution, then added to 7.8 g of aluminum hydroxide slurry, and mixed evenly.

[0035] Step C: Weigh 7.2g urea and 0.53g Na 2 CO 3 Add it into 80g of deionized water to prepare an alkali solution, and directly add the alkali solution to the slurry prepared in step B at 95°C under stirring, then continue the reaction at 98°C for 12 hours, and cool the slurry to room temperature after the reaction. The precipitate was washed by centrifugation until the pH value was less than 8, and the sample was dried in an oven at 100°C for 12 hours to obtain a three-dimensional flower-like LDH product. Elemental analysis shows that the chemical composition formula of the product is: Mg 0.8 Al 0.2 (OH) 2 (CO 3 ) 0.1 0.71H 2 O, BET analysis shows that its specific surface area is 175m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com