Oil well sand flushing temporary plugging agent prepared from waste diapers and its preparation method and application

A technology of diapers and temporary plugging agent, which is applied in the field of oil well sand flushing temporary plugging agent and its preparation, which can solve the problems of sand flushing temporary plugging not mentioned in the product, achieve excellent temporary plugging performance, simple construction process, and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] 1. To recycle waste diapers, peel off the outer fabric of waste diapers, take out the filler (high water-absorbing polyacrylic resin), dry them, pass through a 20-mesh sieve, and put them on a 20-mesh sieve for later use.

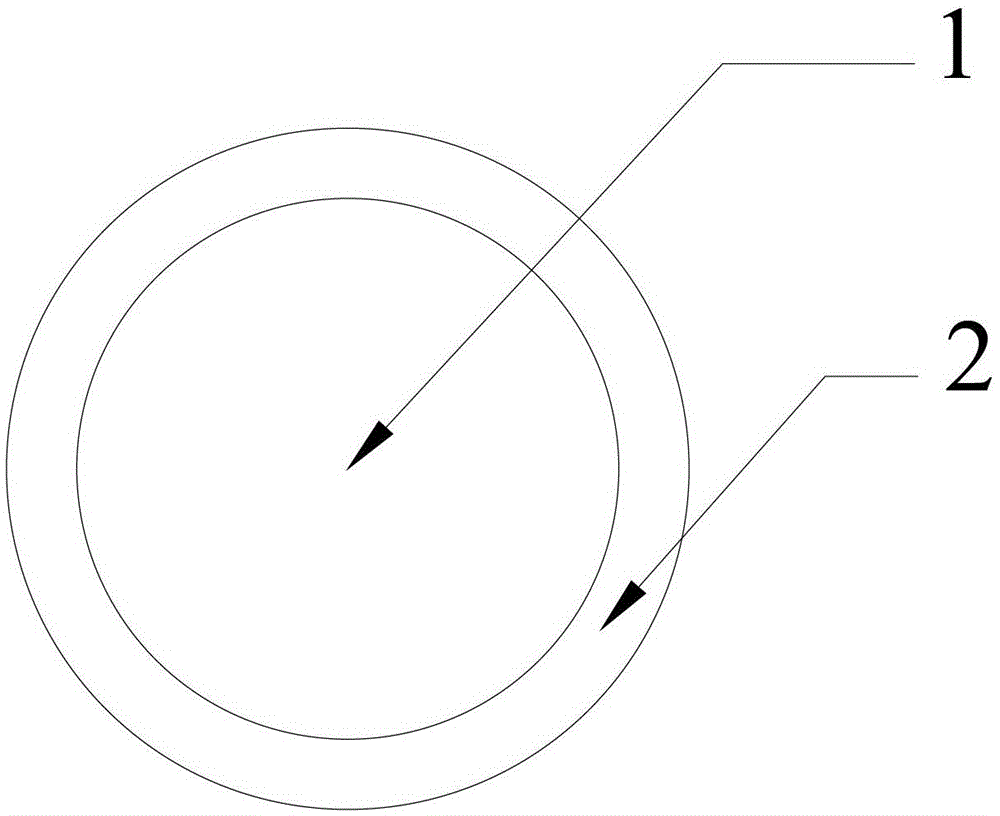

[0048] 2. Dissolve No. 58 industrial paraffin in odorless kerosene (No. 3 jet fuel) to prepare a solution with a mass concentration of 40%, spray evenly on the dried filling to form an industrial paraffin layer, and dry to form dispersed particles, such as figure 1 As shown, the thickness of the coated industrial paraffin layer is 0.1-1mm; the weight ratio of industrial paraffin to the dried filling is 1:8;

[0049] 3. According to the weight ratio of 1.5%, HPAM with a degree of hydrolysis of 18% and a molecular weight of 20 million can be obtained as a finished product.

[0050] 4. In a well in Huanxi Oilfield, due to formation leakage, repeated sand washing failed to achieve the expected effect, so this sand washing technology was used.

[0051] 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com