Stokehole roller way lubricating grease and preparation method thereof

A kind of technology of roller table in front of furnace and grease, applied in the field of grease, can solve the problems of weak adhesion and unfavorable ecological environment protection, and achieve the effect of protecting metal surface, improving poor lubrication and improving extreme pressure performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

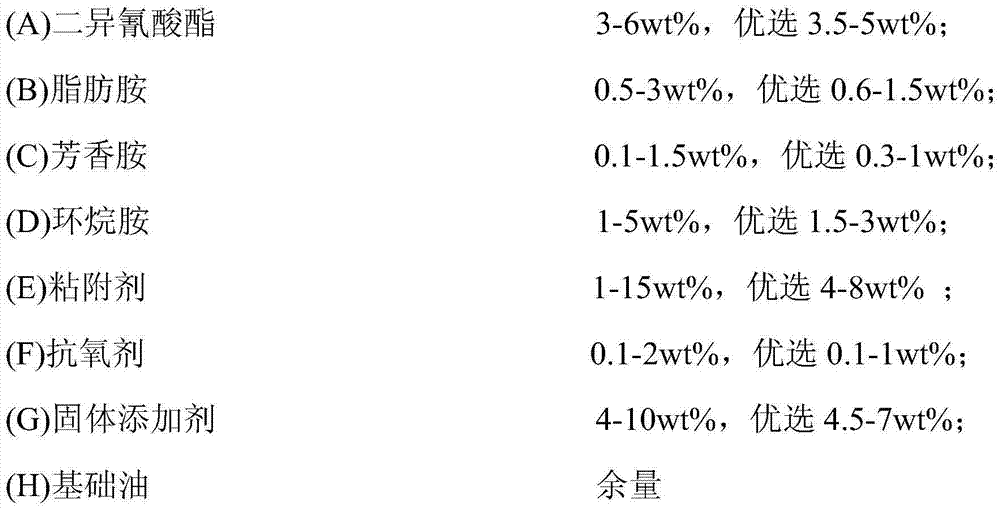

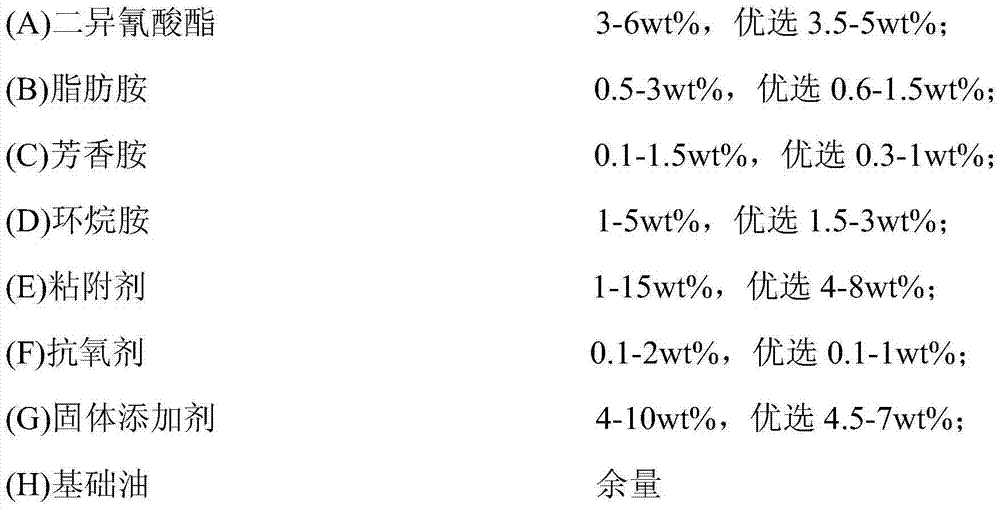

Method used

Image

Examples

preparation example Construction

[0031] The present invention further relates to the preparation method of described furnace front roller table grease, and it comprises the following steps:

[0032] (1) Mix base oil and diisocyanate, which account for 40-50% of the total base oil, according to the formula ratio, and heat to 60-80°C to dissolve;

[0033] (2) Mix the remaining base oil, which accounts for 50-60% of the total base oil, with fatty amine, heat to 60-80°C to dissolve, then add aromatic amine and naphthenic amine, and stir to dissolve;

[0034] (3) Mix the solution obtained in (1) with the solution obtained in (2), turn on the fan, stir at a constant temperature, then raise the temperature to 120°C, and then continue to heat up to 130-160°C, keep warm; preferably stir at a constant temperature for 10- 30min; preferably keep warm for 20min-2h;

[0035] (4) When cooling down to 100-120°C, add antioxidant, adhesive and solid additives, stir evenly, and leave the kettle.

Embodiment 1

[0038] Add 300kg of trimellitate Emkarate1938 (Croda Company, Inc, the same below) and 29.2kg of diphenylmethane-4,4-diisocyanate (Aike Reagent) to the grease making kettle, heat to 75°C to dissolve At the same time, in another reaction kettle with 300kg of trimellitate Emkarate1938, add 6.6kg of octadecylamine (Nanjing Jinlong Chemical Group Co., Ltd., the same below), heat to 75°C to dissolve, and then add 14.8kg of cyclohexylamine Amine (Shandong Huayang Group, the same below) and 3.56kg aniline (Shandong Haihua Co., Ltd., the same below), the mixed solution in the reaction kettle is quickly put into the fat-making kettle, the fan is turned on, and the temperature is raised to 120°C, then continue to heat up to 150°C, keep warm for 20 minutes, cool down to 110°C, add 1.8kg of p-octyl diphenylamine Vanlube81 (R.T.Vanderbilt Company, Inc, the same below), 36kg of high-viscosity complex ester Priolube3986 (Croda Company, Inc, hereinafter the same), 36kg colloidal graphite 00# ...

Embodiment 2

[0042] Add 300kg of paraffinic base oil 500SN (Zhonghai Nanlian Petrochemical Co., Ltd., the same below) and 32.3kg of toluene diisocyanate (Shanghai Reagent No. 300kg500SN, add 9kg of dodecylamine (Nanjing Hengxin Chemical Co., Ltd.), heat to 80°C to dissolve, then add 21kg of cyclohexylamine and 6.8Kg of aniline, add the mixed solution in the reaction kettle to the fat making kettle, open Fan, keep stirring at 80°C for 15 minutes, then raise the temperature to 120°C, and finally raise the temperature to 160°C, and keep it warm for 1h. Cool down to 110°C, add 1.8kg of p-octyl diphenylamine Vanlube81, 60kg of high-viscosity complex ester Priolube3986, 48kg of colloidal graphite 00#, and homogeneously grind to obtain a finished product.

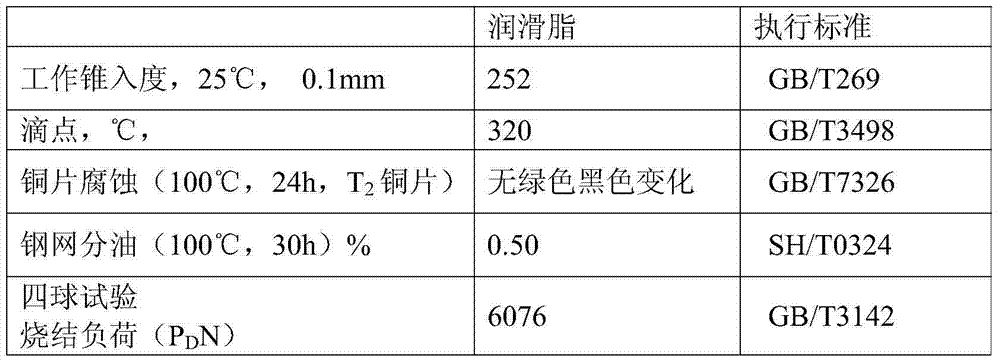

[0043] The detection data of embodiment 2

[0044]

[0045]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com