Amphiprotic acrylic resin leather tanning agent

A technology of acrylic resin and leather, which is applied in the field of synthesis of leather chemicals, can solve problems such as discoloration, and achieve the effects of reduced dosage, excellent water solubility, and excellent application performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

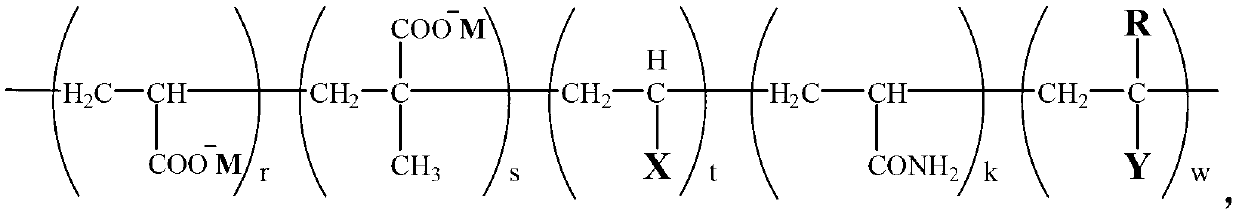

Image

Examples

Embodiment 1

[0021] A kind of preparation method of amphoteric acrylic resin leather tanning agent comprises the following steps:

[0022] 1) Dissolve 12.0 grams of acrylic acid and 12.0 grams of methacrylic acid in 59.4 grams of deionized water, stir at 10-20 ° C, add 40.8 grams of 30% sodium hydroxide aqueous solution dropwise in 30 minutes, and then add it in 10 React at ~20°C for 15 minutes to obtain monomer aqueous solution A;

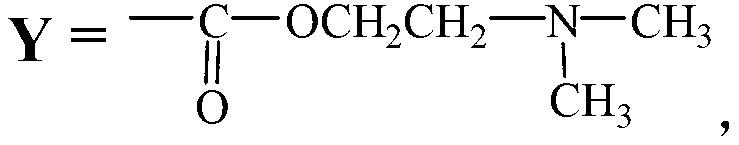

[0023] 6.0 grams of dimethylaminoethyl acrylate, 18.0 grams of acrylamide, and 3.0 grams of ethylene glycol were dissolved in 50.0 grams of deionized water to obtain monomer aqueous solution B;

[0024] Make the initiator aqueous solution C of mass concentration 5% with 2.4 grams of ammonium persulfate;

[0025] 2) Add 12.0 grams of allyl polyether APEG-500 and 25.0 grams of deionized water into the reactor equipped with a stirrer and a reflux condenser, stir and raise the temperature to 75-80°C, and add dropwise within 2.5-3.0 hours Step 1) The prepared mon...

Embodiment 2

[0027] A kind of preparation method of amphoteric acrylic resin leather tanning agent comprises the following steps:

[0028] 1) Dissolve 15.0 grams of acrylic acid and 15.0 grams of methacrylic acid in 44.6 grams of deionized water, stir at 10-20°C, add 71.4 grams of potassium hydroxide aqueous solution with a mass concentration of 30% within 1 hour, and place in the React at 10-20°C for 15 minutes to obtain monomer aqueous solution A;

[0029] 12.0 grams of dimethylaminoethyl methacrylate, 12.0 grams of acrylamide, and 4.0 grams of isopropanol were dissolved in 50.0 grams of deionized water to obtain monomer aqueous solution B;

[0030] Make the initiator aqueous solution C of mass concentration 5% with 3.6 grams of ammonium persulfate;

[0031] 2) Add 6.0 grams of allyl polyether APEG-700 and 15.0 grams of deionized water into the reactor equipped with a stirrer and a reflux condenser, stir and raise the temperature to 75-80°C, and add dropwise within 2.5-3.0 hours Step 1...

Embodiment 3

[0033] A kind of preparation method of amphoteric acrylic resin leather tanning agent comprises the following steps:

[0034] 1) Dissolve 6.0 grams of acrylic acid and 6.0 grams of methacrylic acid in 55.8 grams of deionized water, stir at 10-20 ° C, add 29.1 grams of monoethanolamine aqueous solution with a mass concentration of 30% dropwise within 30 minutes, and after the addition is completed, in 10 React at ~20°C for 15 minutes to obtain monomer aqueous solution A;

[0035] 18.0 grams of dimethylaminoethyl acrylate, 12.0 grams of acrylamide, and 5.0 grams of ethylene glycol were dissolved in 50.0 grams of deionized water to obtain monomer aqueous solution B;

[0036] Make the initiator aqueous solution C of mass concentration 5% with 1.8 gram of ammonium persulfate;

[0037] 2) Add 18.0 grams of allyl polyether APEG-1000 and 40.0 grams of deionized water into the reactor equipped with a stirrer and a reflux condenser, stir and raise the temperature to 75-80°C, and add dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com