Plasma enhanced chemical vapor deposition (PECVD) device

A vapor chamber and reaction chamber technology, applied in gaseous chemical plating, metal material coating process, coating, etc., can solve the problems of bulky devices, inconvenient operation for maintenance personnel, and small gaps between them

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

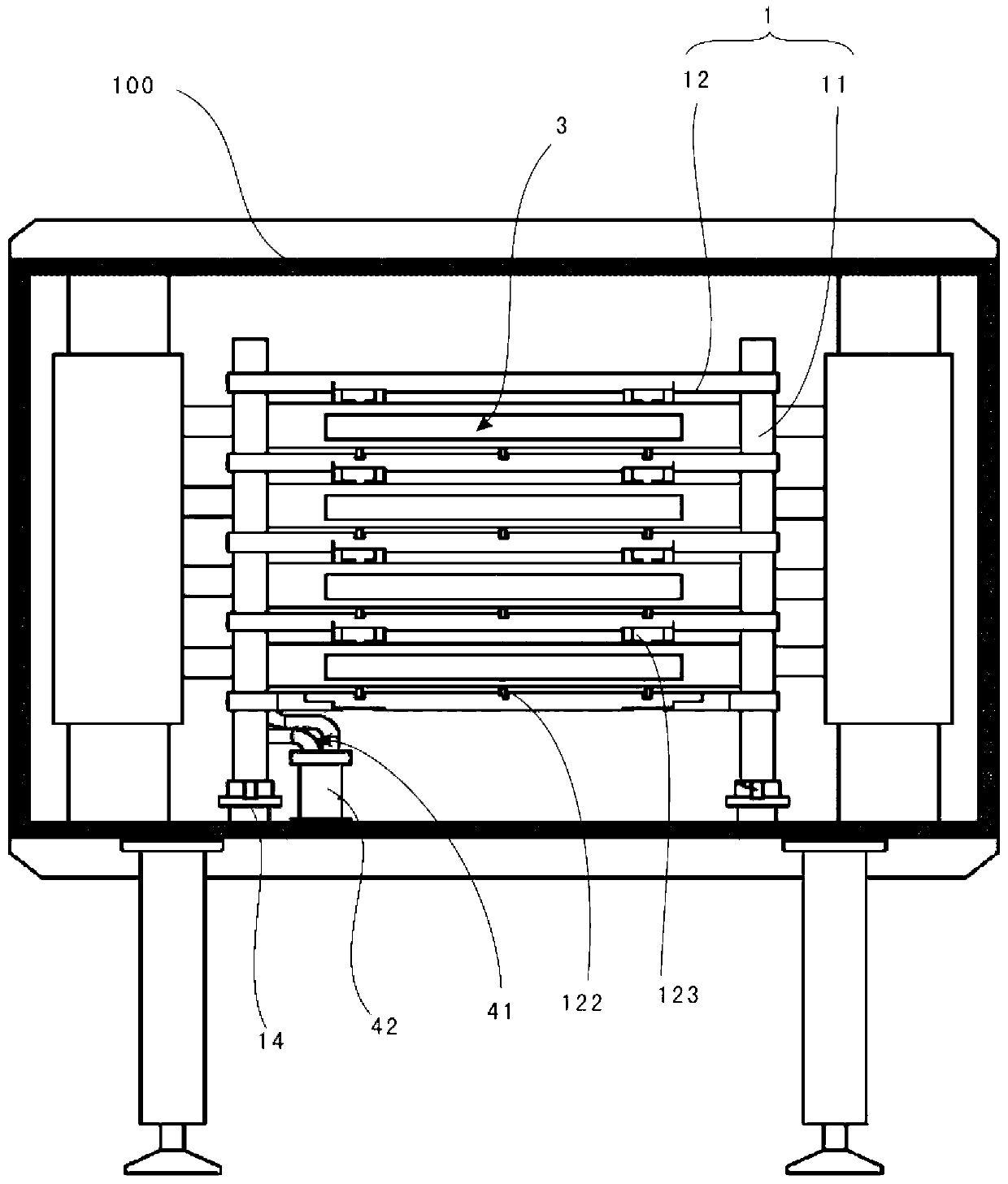

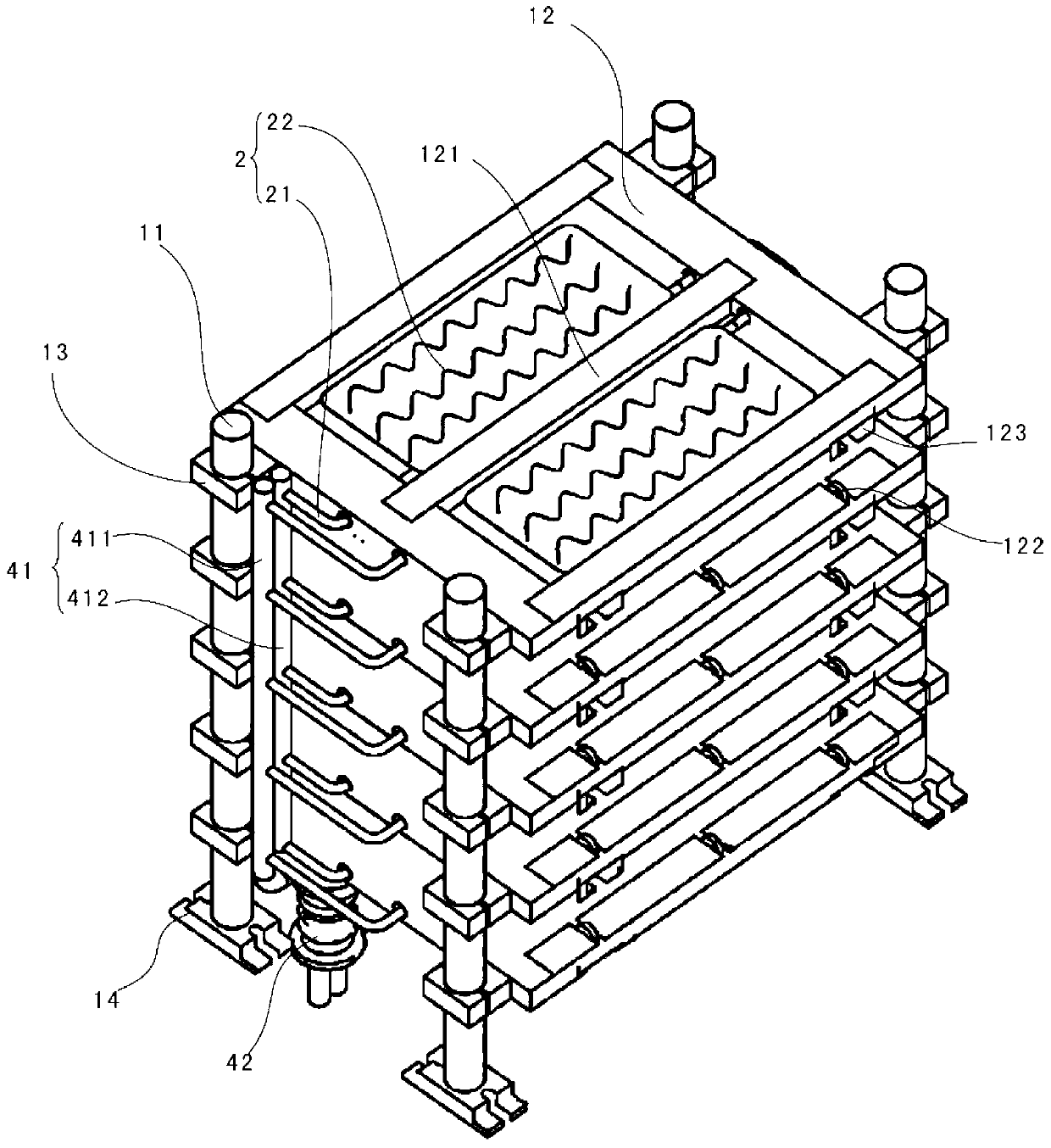

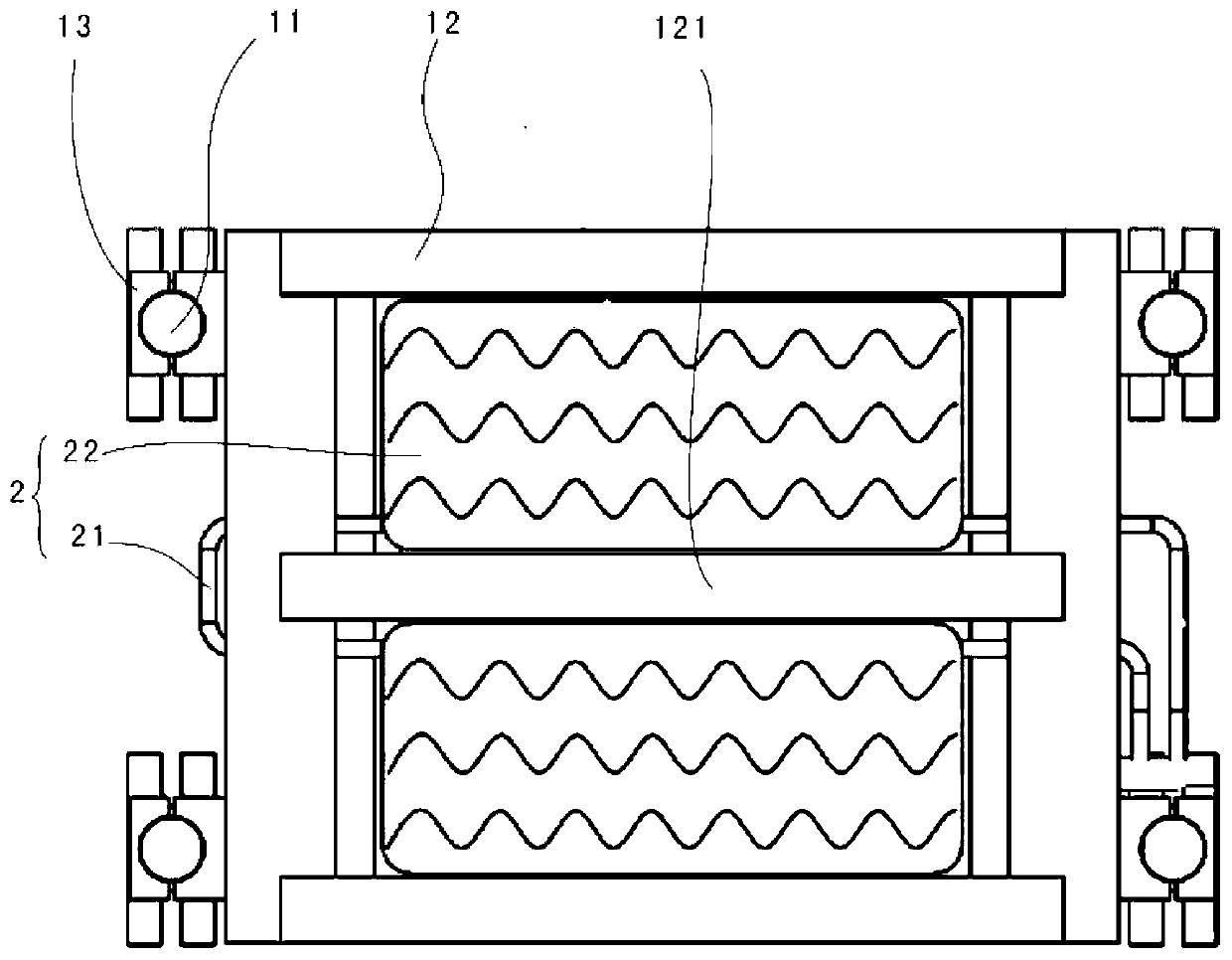

[0024] see figure 1 , a PECVD device provided in a preferred embodiment of the present invention, including a process chamber 100, and a carrier 1 and five cooling vapor chambers 2 (such as figure 2 shown) and four reaction chambers 3.

[0025] In this embodiment, the process chamber 100 is in the shape of a square as a whole, and a stainless steel mirror heat-insulating reflector is installed on its inner surface, which can effectively prevent heat from being emitted to the external environment in the form of radiation, and further save energy.

[0026] Such as figure 1 , figure 2 As shown, the carrier 1 is slidably placed in the process chamber 100 . A pulley 14 is installed on the bottom of the carrier frame 1. In this embodiment, the carrier frame 1 includes four sup...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com