Aluminum shell battery thermal insulation protective film

A technology of aluminum shell battery and protective film, which is applied in the direction of pressure-sensitive film/sheet, film/sheet release liner, film/sheet adhesive, etc. Energy and heat preservation and other issues, to achieve the effect of strong heat insulation and heat preservation, which is beneficial to battery capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

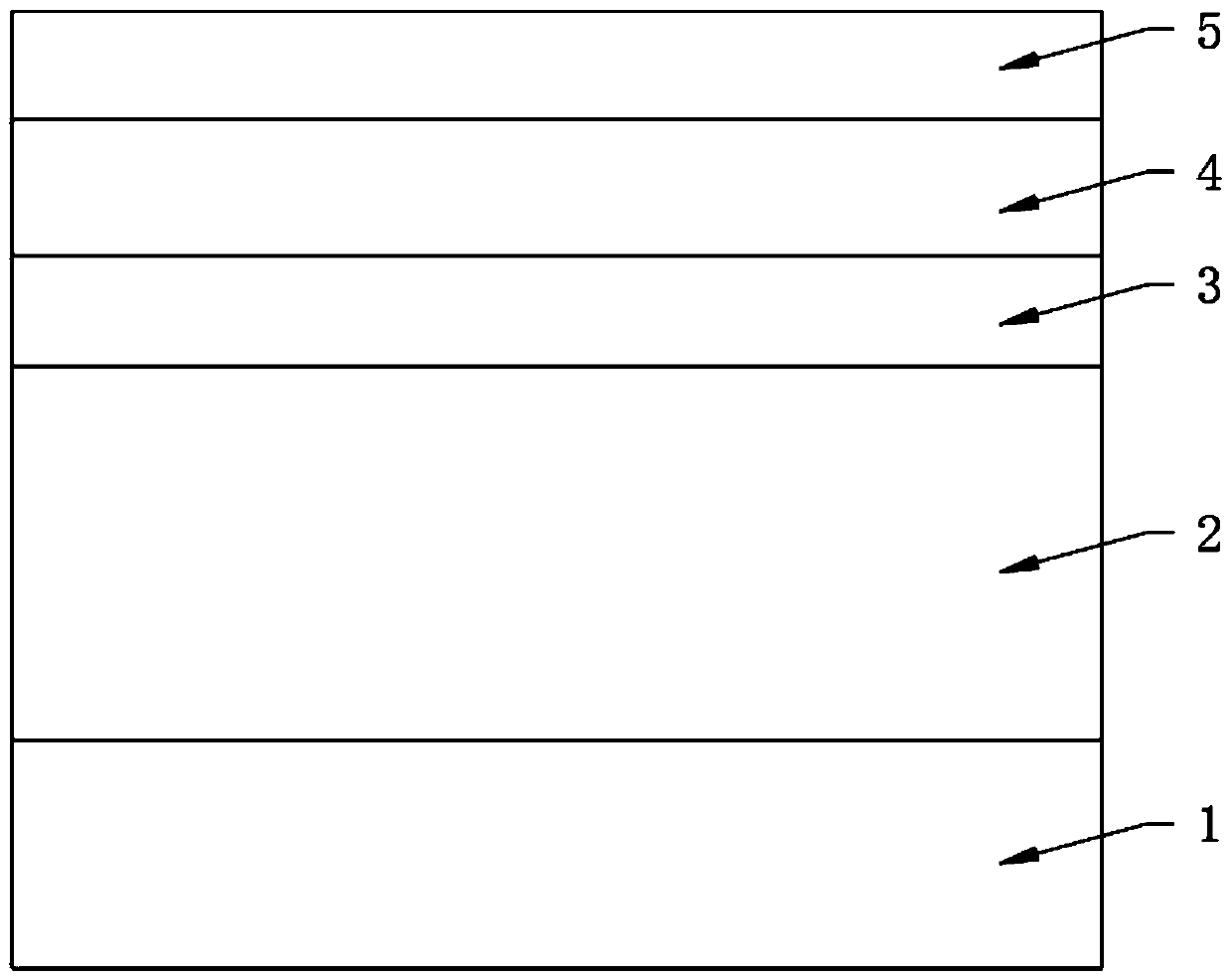

[0022] see figure 1 , the present invention provides the following technical solutions: an aluminum shell battery heat preservation protective film, comprising a closed-cell foam layer 1, an energy storage layer 2, a plastic substrate 3, a pressure-sensitive adhesive layer 4 and a release film 5;

[0023] The closed-cell foam layer 1 is a polyethylene closed-cell foam material;

[0024] The energy storage layer 2 is a cross-linked polymer of hexamethylene diisocyanate and polyethylene glycol;

[0025] The plastic substrate 3 is one of polyethylene, polypropylene, polyvinyl chloride, polyolefin, polyester, and polyimide;

[0026] The pressure-sensitive adhesive layer 4 is one of silicone, polyurethane, polyacrylate, and rubber-type pressure-sensitive adhesives;

[0027] The release film 5 is one of a silicon release film or release paper, a fluorine release film or release paper, and a non-silicon and non-fluorine release film.

[0028] Specifically, the thickness of the clo...

Embodiment 2

[0035] see figure 1 , the present invention provides the following technical solutions: an aluminum shell battery heat preservation protective film, comprising a closed-cell foam layer 1, an energy storage layer 2, a plastic substrate 3, a pressure-sensitive adhesive layer 4 and a release film 5;

[0036] The closed-cell foam layer 1 is a closed-cell foam material of polyethylene or ethylene-propylene copolymer;

[0037] The energy storage layer 2 is a cross-linked polymer of HDI trimer and polyethylene glycol;

[0038] The plastic substrate 3 is polyethylene;

[0039] The pressure-sensitive adhesive layer 4 is one of silicone, polyurethane, polyacrylate, and rubber-type pressure-sensitive adhesives;

[0040] The release film 5 is one of a silicon release film or release paper, a fluorine release film or release paper, and a non-silicon and non-fluorine release film.

[0041] Specifically, the thickness of the closed-cell foam layer 1 is 20 μm.

[0042] Specifically, the t...

Embodiment 3

[0048] see figure 1 , the present invention provides the following technical solutions: an aluminum case battery thermal insulation protective film, comprising a closed-cell foam layer 1, an energy storage layer 2, a plastic substrate 3, a pressure-sensitive adhesive layer 4 and a release film 5;

[0049] The closed-cell foam layer 1 is one of closed-cell foam materials such as polyethylene, polypropylene, ethylene-propylene copolymer, polystyrene, and rubber;

[0050] The energy storage layer 2 is a cross-linked polymer of polyisocyanate and polyethylene glycol;

[0051] The plastic substrate 3 is one of polyethylene, polypropylene, polyvinyl chloride, polyolefin, polyester, and polyimide;

[0052] The pressure-sensitive adhesive layer 4 is one of silicone, polyurethane, polyacrylate, and rubber-type pressure-sensitive adhesives;

[0053] The release film 5 is one of a silicon release film or release paper, a fluorine release film or release paper, and a non-silicon and non...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com