Scattered pile and strong net foundation leveling system for steeled storage tank foundations

A storage tank foundation and foundation technology, which is applied in the field of foundation leveling system with sparse piles and strong nets, can solve the problems of difficult construction, poor earthquake resistance, and large number of pile foundations, and achieve low construction difficulty, increase bearing capacity, and increase the number of pile foundations. little effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-2

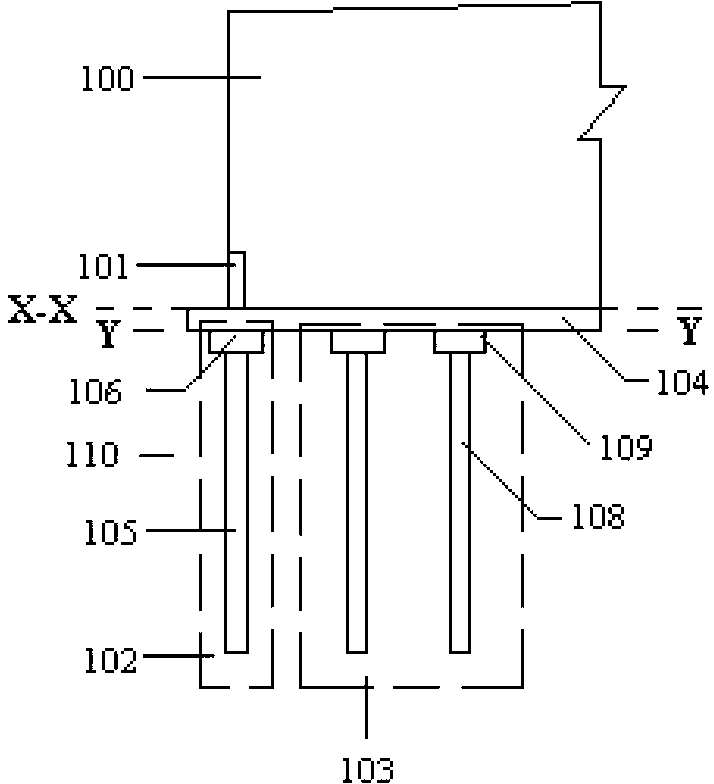

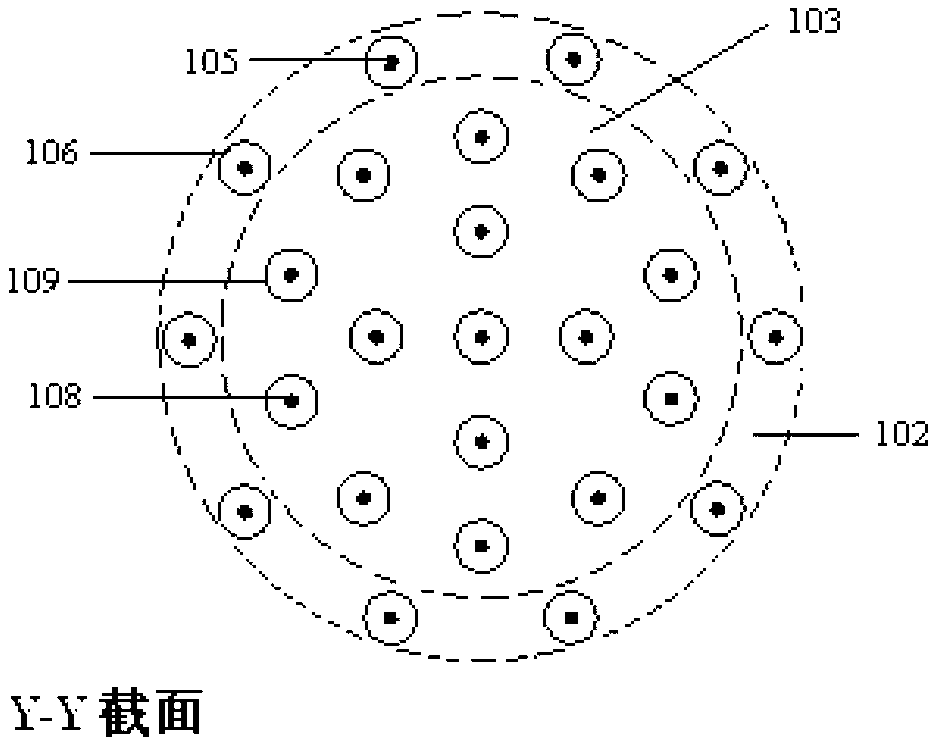

[0047] Embodiment 1-2 This embodiment is completely the same as Embodiment 1-1 except that the following technical data are different from Embodiment 1-1.

[0048] The reinforced pile pile cap 109 is a cylinder, and the diameter of the top surface of the cylinder is 5d 2 , that is, 1200mm×5=6.0m, and the thickness is 1.5m.

Embodiment 1-3

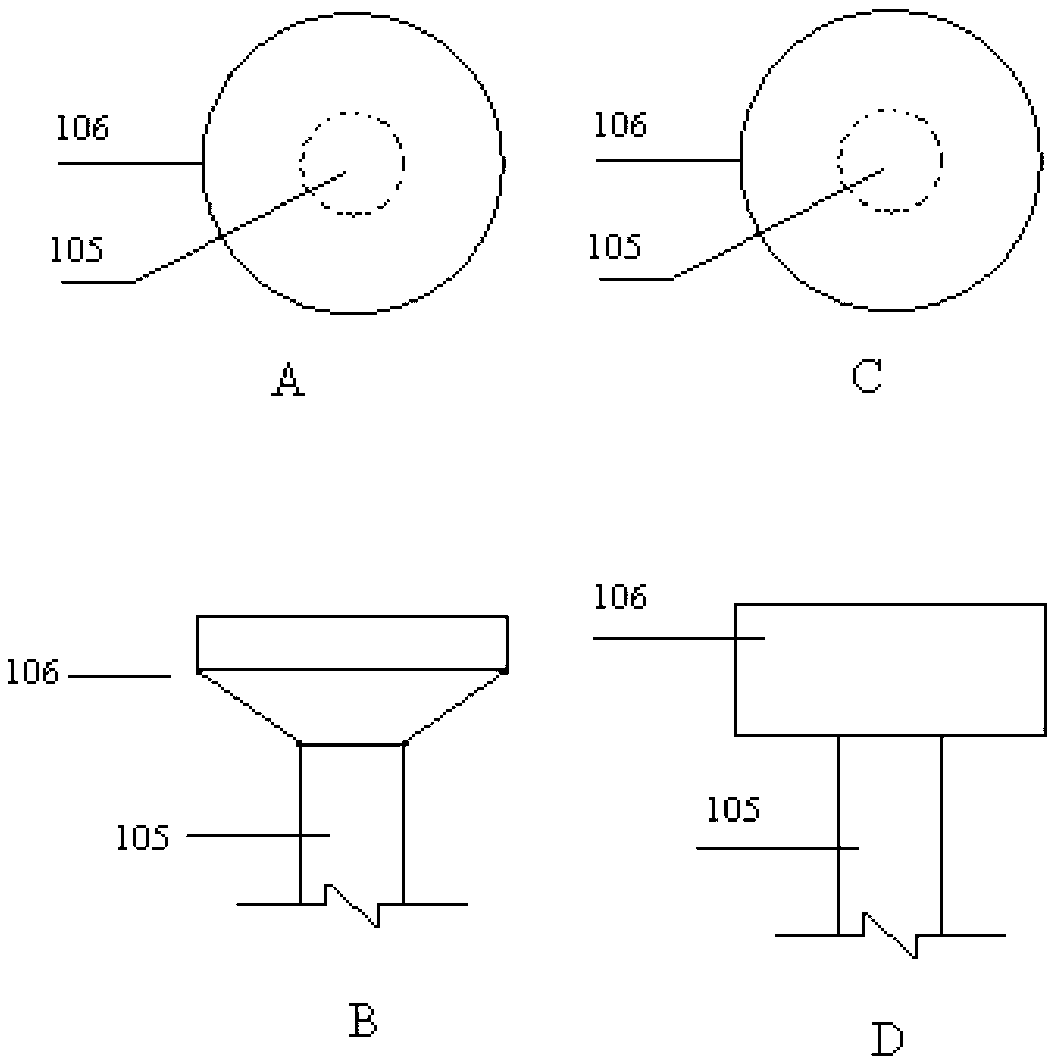

[0049] Embodiment 1-3 This embodiment is completely the same as Embodiment 1-1 except that the following technical data are different from Embodiment 1-1.

[0050] The supporting pile pile cap 106 is a cylinder, and the diameter of the top surface of the cylinder is 5d 1 , that is, 1600mm×5=8.0m, and the thickness is 1.5m.

Embodiment 1-4

[0051] Embodiment 1-4 This embodiment is completely the same as Embodiment 1-1 except that the following technical data are different from Embodiment 1-1.

[0052] The supporting pile pile cap 106 is a cylinder, and the diameter of the top surface of the cylinder is 5d 1 , namely 1600mm×5=8.0m, the thickness is 1.5m;

[0053] The reinforced pile pile cap 109 is a cylinder, and the diameter of the top surface of the cylinder is 5d 2 , that is, 1200mm×5=6.0m, and the thickness is 1.5m.

[0054] Example 2-1 Foundation Leveling System for Differential Settlement Control Prepared for the Construction of a Crude Oil Steel Storage Tank with a Reserve of 100,000 Cubic Meters

[0055] The crude oil steel storage tank is planned to be built on a soft soil foundation, and the surface layer of the soft soil foundation 110 is covered with a hard shell layer with a thickness of 8m and a characteristic value of the foundation bearing capacity of 255kPa;

[0056] The leveling system is ins...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com