Ribbed steel tube concrete column and its design method

A technology of concrete column and design method, which is applied to columns, piers, pillars, etc., can solve the problems of increasing welding workload and processing costs, increasing the complexity of steel pipe processing, increasing the wall thickness of steel pipes, and shortening the processing period. , high rigidity, the effect of reducing wall thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

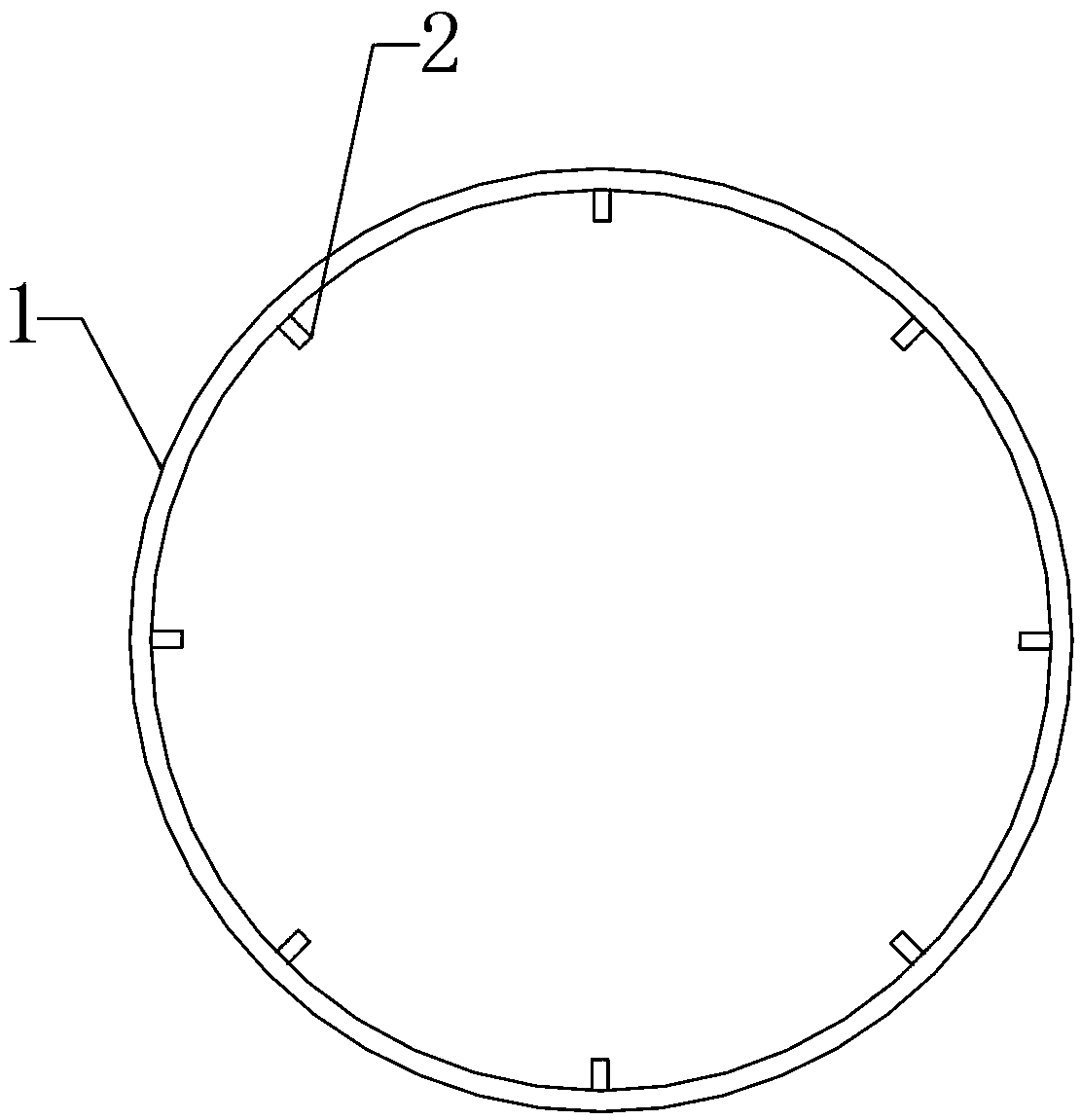

[0046] Such as figure 1 As shown, the ribbed steel pipe is a round steel pipe. During the manufacturing process, the steel plate 1 is continuously rolled on a rolling mill of a steel factory, and a plurality of ribs 2 are rolled on the rolling surface.

[0047] The distribution of ribs on the ribbed steel plate can have the following situations:

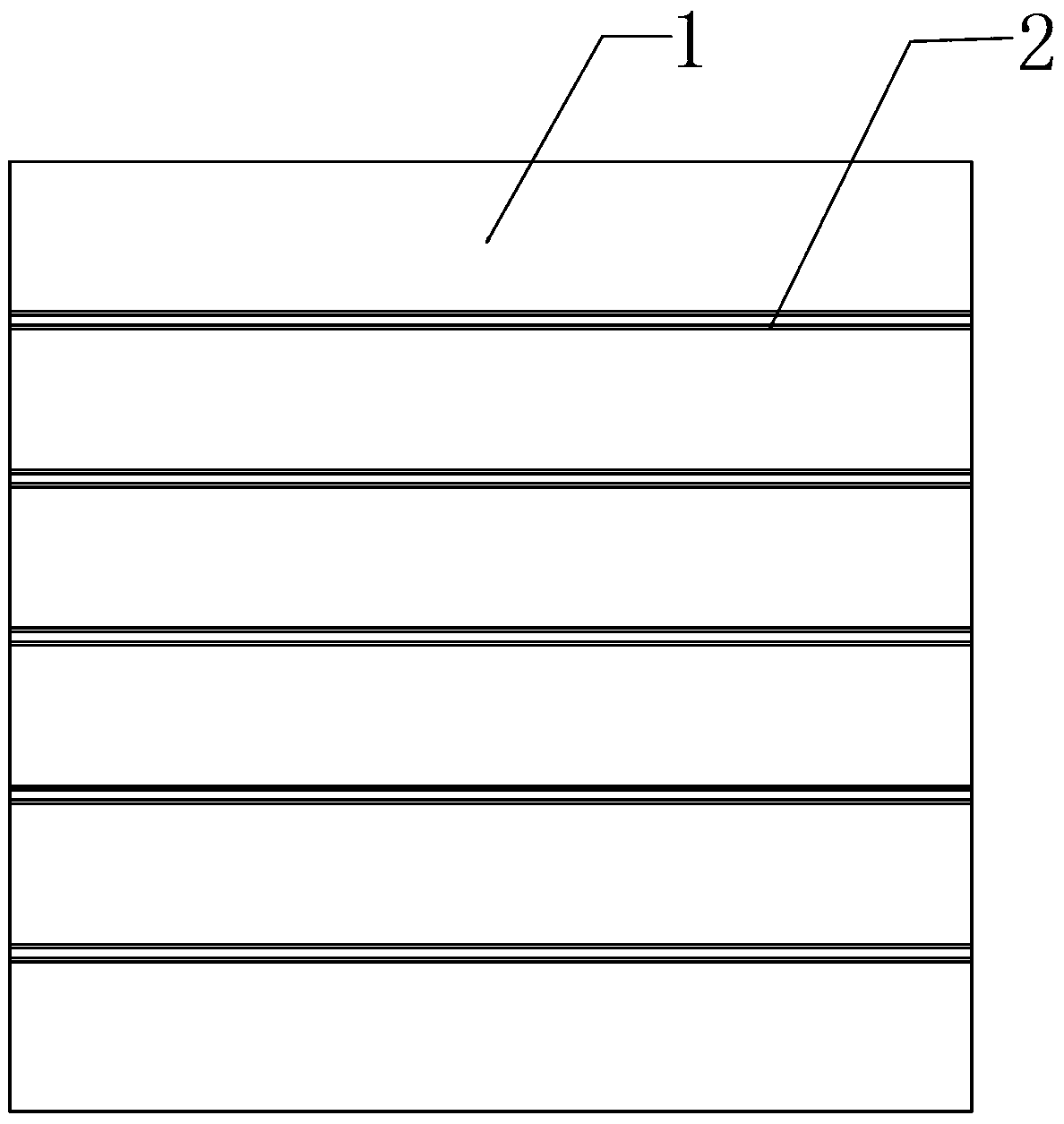

[0048] Such as Figure 3-Figure 5 As shown, the ribs on the ribbed steel plate are distributed on one or both sides of the steel plate.

[0049] Such as image 3 , Figure 6-Figure 7 As shown, the ribs on the ribbed steel plate are continuous or discontinuous; the ribs are horizontally parallel or obliquely parallel.

[0050] The further operation of the rolled ribbed steel plate is: roll the ribbed steel plate into a cylindrical shape, and attach and weld the two welded ends to finally become a ribbed steel pipe.

[0051] The finished ribbed steel pipe will be further explained according to the distribution of the ribs. For s...

Embodiment 2

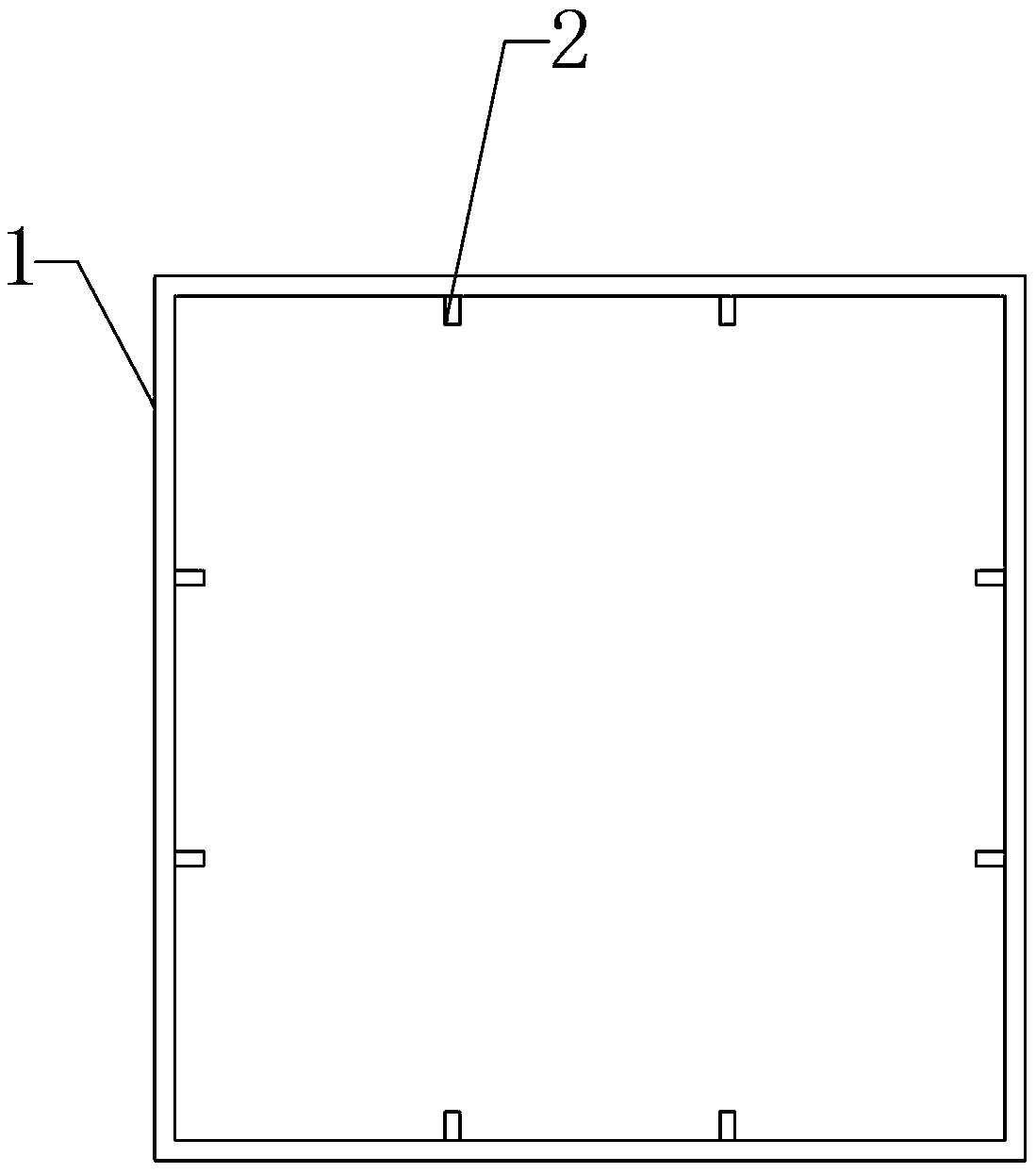

[0054] Such as figure 2 As shown, the ribbed steel pipe is a square steel pipe. During the production process, the steel plate is continuously rolled on the rolling mill of the steel mill, and multiple ribs are rolled on the rolling surface.

[0055] The distribution of ribs on the ribbed steel plate can have the following situations:

[0056] Such as Figure 3-Figure 5 As shown, the ribs on the ribbed steel plate are distributed on one or both sides of the steel plate.

[0057] Such as image 3 , Figure 6-Figure 7 As shown, the ribs on the ribbed steel plate are continuous or discontinuous; the ribs are horizontally parallel or obliquely parallel.

[0058] Since square steel pipes are complicated to be rolled or bent, the further operation of the rolled ribbed steel plate is as follows:

[0059] For welding and forming of four ribbed steel plates:

[0060] The four ribbed steel plates are provided with grooves on their respective welding ends, and the direction of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com