Temperature control system for controlling optical fiber temperature excursion and application method of temperature control system

A temperature control system and optical fiber technology, applied in the direction of temperature control without auxiliary power supply, can solve the problem of affecting the temperature measurement effect, it is difficult to ensure that the distance measurement signal is not distorted, etc., to achieve reliable performance, measurement accuracy and interchangeability Good, small temperature drift effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

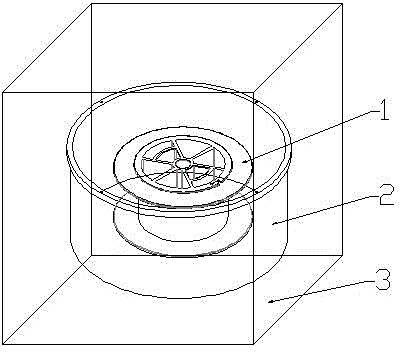

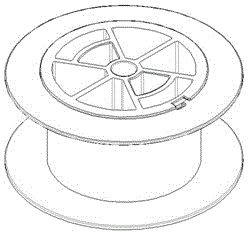

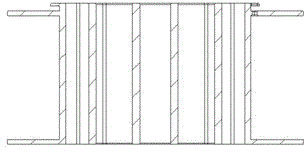

[0018] Such as figure 1 As shown, a temperature control system for controlling optical fiber temperature drift includes an optical fiber winding device 1 , an aluminum alloy cylinder 2 , and a glass fiber reinforced plastic cube box 3 . The optical fiber winder 1 with the optical fiber is placed inside the aluminum alloy cylinder 2, and the interior of the aluminum alloy cylinder 2 is filled with deionized water, and the deionized water submerges the optical fiber winder 1, and the body of the aluminum alloy cylinder 2 Add a sealing ring to seal between 6 and the cylinder cover 5 . The aluminum alloy cylinder 2 is suspended in the FRP cube box 3, and the gap between the aluminum alloy cylinder 2 and the FRP cube box 3 is filled with heat-insulating airgel 4. The outer wall of the whole fiberglass cube box 3 is wrapped with multi-layer heat insulating material.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com