Ultrasonic resonance spectrum detection method for fatigue hardening layer of roll

A fatigue-hardened layer and detection method technology, applied in the direction of length measuring device, metal rolling, metal rolling, etc., can solve the problems of unsuitability for fatigue-hardened layer, large data dispersion, large workload, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The specific implementation of the present invention will be described in detail below in conjunction with the drawings of the embodiments.

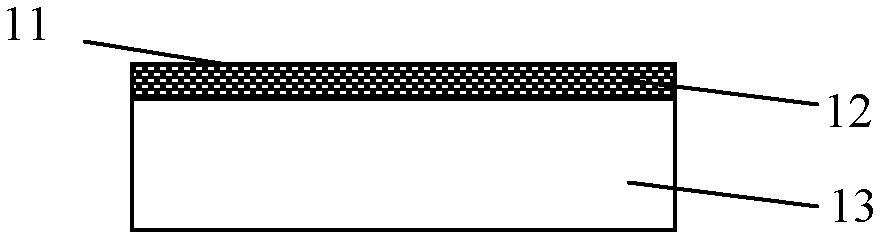

[0046] For different used rolls, such as cold-rolled work rolls, cold-rolled backup rolls, hot-rolled backup rolls, etc., such as figure 1 As shown, below the roll surface 11 is the fatigue hardened layer 12 first, and then the roll working layer 13.

[0047] After the fatigue hardened layer is formed by the used rolls, the structure of the fatigue hardened layer will be different from that of the working layer matrix. The analysis shows that the lath martensite boundary of the material matrix with a depth of less than 1mm on the surface is clearly distinguishable, and it is not affected. Contact fatigue is affected, while the boundary of the sample at 10 microns is blurred, and the structure looks like secondary grains, which is affected by contact fatigue.

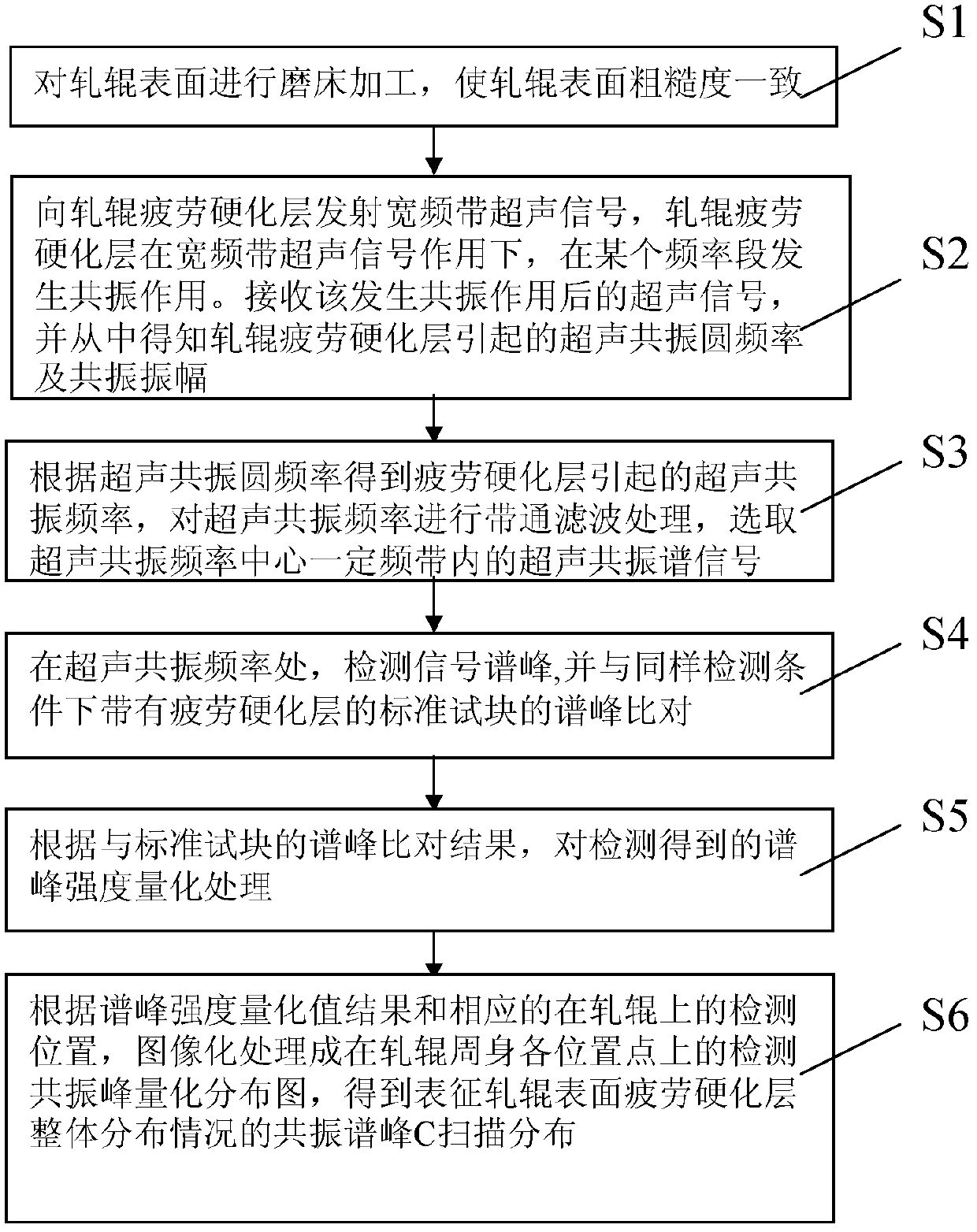

[0048] The present invention is to perform ultrasonic resonance spectrum detec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com