Magnesium alloy stamping process

A magnesium alloy and process technology, applied in the field of magnesium alloy stamping process, can solve the problems of increased thickness distribution difference of stamping parts, affect the dimensional stability of stamping parts, limit the stamping performance of stamping parts, etc., achieve uniform thickness distribution and improve stamping performance , to ensure the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

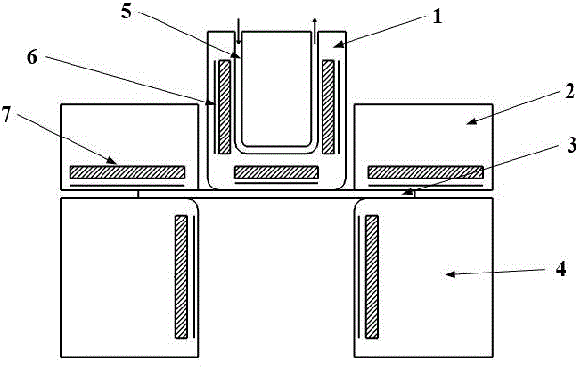

[0022] Such as figure 1 Shown is the structural schematic diagram of the mold that implements magnesium alloy stamping process of the present invention, and this mold comprises punch 1, die 4 and crimping die 2, and the resistance wire 7 that is used for heating is all arranged in die 4 and crimping die 2 1. A thermocouple 6 for precise control of the heating temperature, a resistance wire 7 for heating, a thermocouple 6 for precise control of the heating temperature and a circulating cooling channel 5 for controlling the temperature of the punch at a low temperature are arranged in the punch 1, Magnesium alloy stamping process of the present invention, its stamping steps are as follows:

[0023] 1) Before stamping, the magnesium alloy sheet 3 coated with high temperature resistant oil is placed between the die 4 and the blank holder 2, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com