Anti-oxidation program controlled accurate loading experiment device and method for super-plasticity free bulging through photoelectric measurement

A technology of photoelectric measurement and loading experiment, which is applied in the field of superplastic bulging experiment device, can solve problems such as unsatisfactory and rough results, achieve precise pressure measurement and control, temperature measurement and control, delay grain growth, and reduce additional effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

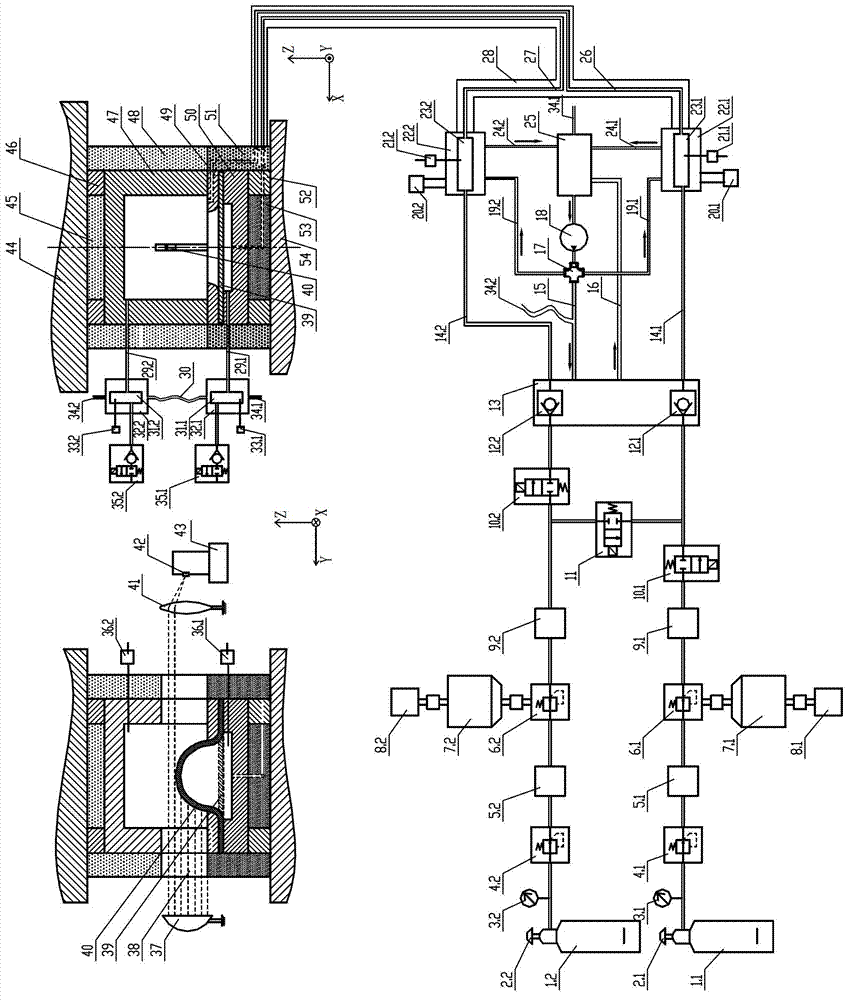

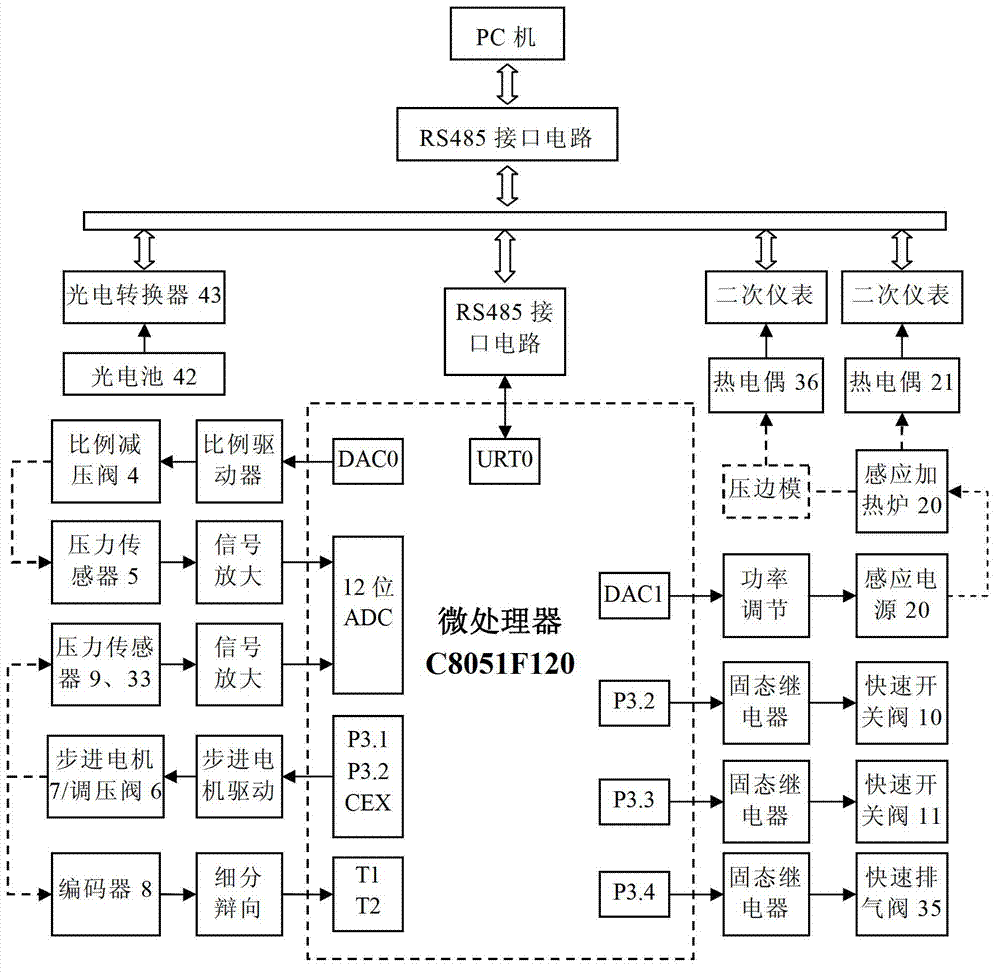

[0032] The specific content and implementation method of the present invention will be further described below in conjunction with the accompanying drawings and embodiments. attached figure 1 It is a structural diagram of the superplastic free bulging experimental device of the present invention, with figure 2 It is a structural diagram of the control system of the present invention.

[0033] A superplastic photoelectric measurement free bulging anti-oxidation program control precise loading experimental device, the experimental device is mainly composed of I and II two anti-oxidation heating / loading systems, a pole height photoelectric measurement system and a cooling system. In the two-way anti-oxidation heating / loading system, the first line is a positive pressure loading system, and the second line is a back pressure loading system, both of which are composed of a purified high-pressure argon gas source, a heating and loading gas line with pressure and temperature measur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com