Inertia friction welding clamping mechanism for front drum of engine

A technology of inertia friction welding and clamping mechanism, which is applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems of high work intensity, achieve the effects of improving quality and production efficiency, reducing vibration, and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

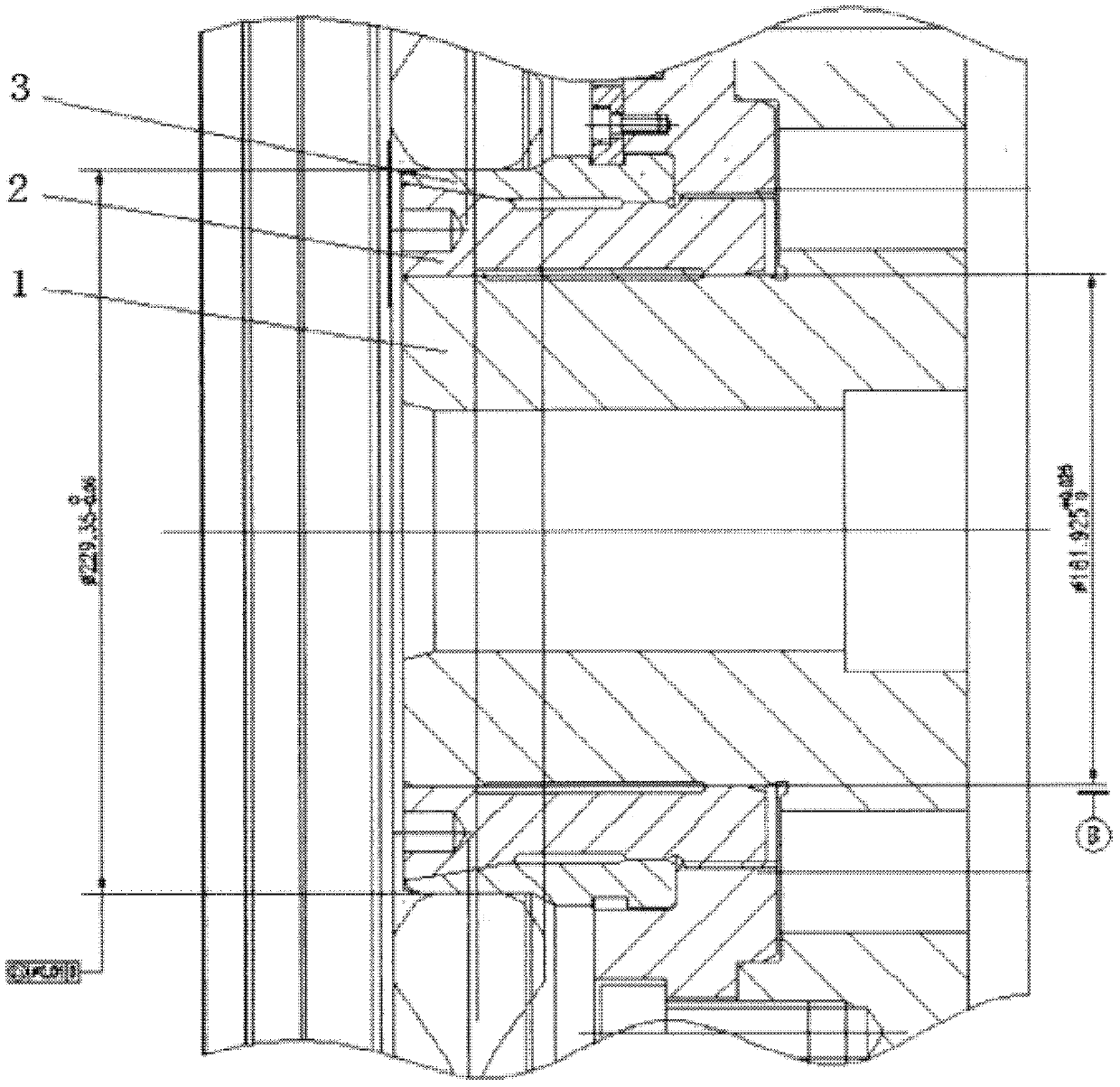

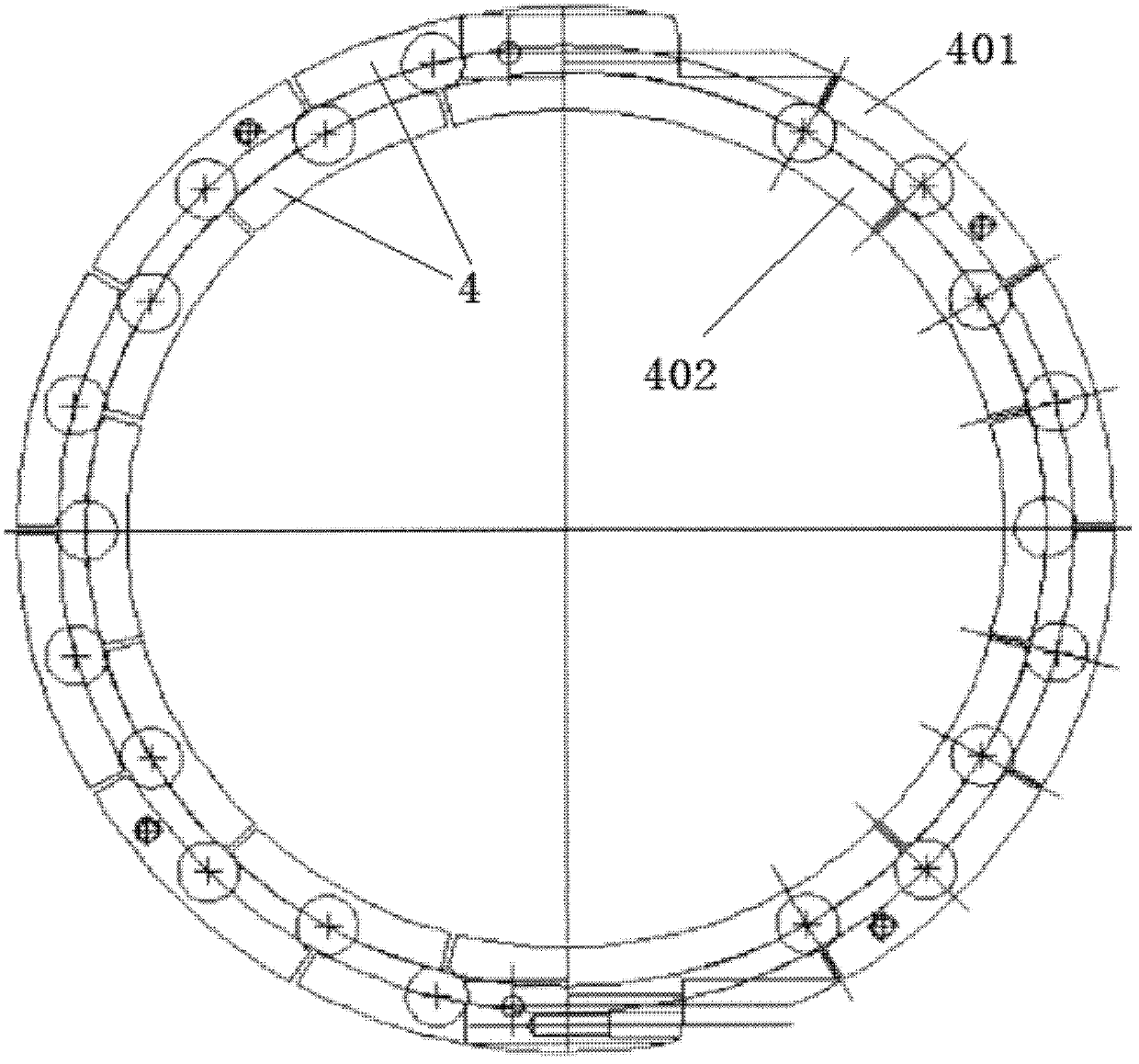

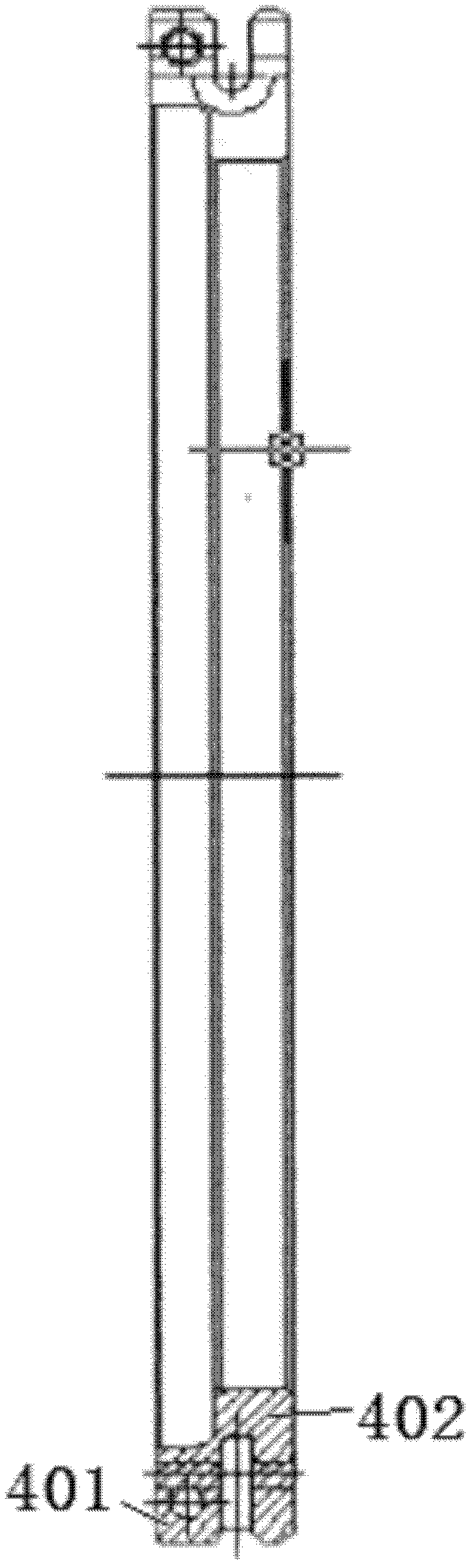

[0036] A clamping mechanism for inertial friction welding of the front drum of an engine, which adopts a clamping structure combining machinery, hydraulic system and low-temperature grease tensioning mechanism; wherein:

[0037] The tailstock fixture clamps the processed parts with a mechanical clamping structure of inner and outer cones; in order to enhance the welding reliability, an elastic half ring is used to fasten the processed parts at the part welding to increase the strength and control the welding deformation of the parts; the main shaft fixture adopts low temperature Grease tensioning mechanism, corresponding sealing application of O-ring and semi-arc-shaped supporting rubber ring sealing structure and correspondingly consistent with the oil circuit interface of the equipment.

[0038] The specific configuration of the tailstock fixture is as follows: an inner taper sleeve 2 and an outer taper sleeve 3; the two are installed in pairs on the outside of the positionin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com