Method for removing odor of refined salt through ferric salt

A technology for refining salt and high-iron salt, applied in the field of salt chemical industry, which can solve the problems of resin replacement, troublesome regeneration, high one-time investment, and difficult operation, etc., and achieve low production cost, simple process operation, and good elimination effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

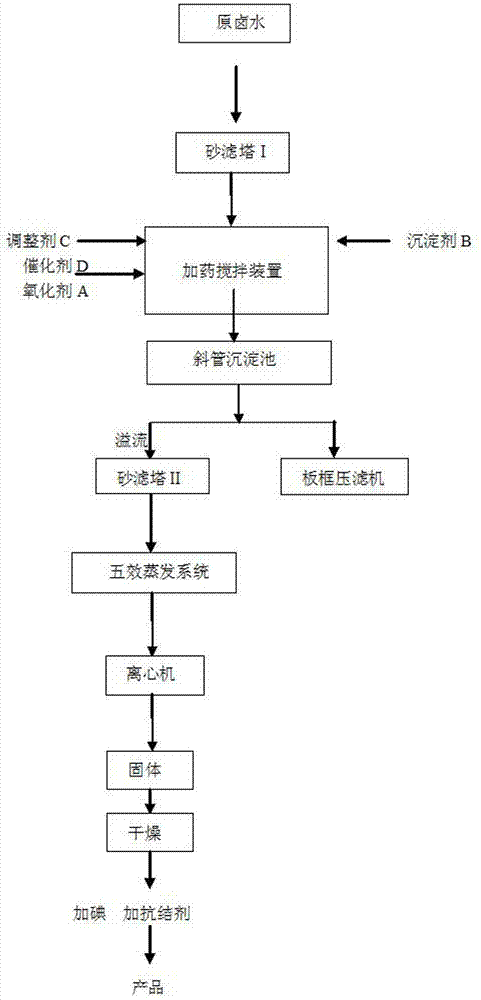

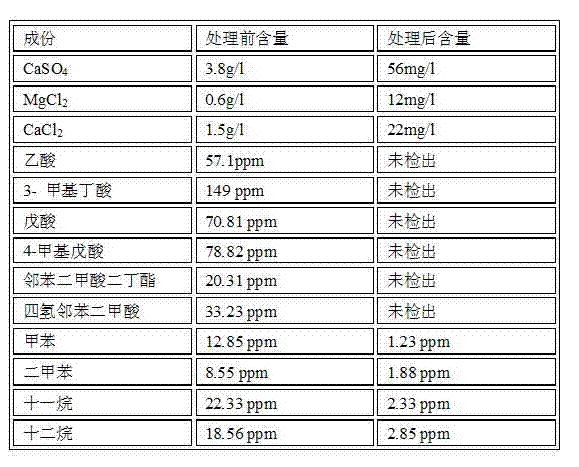

[0029] 1. The raw brine passes through the sand filter tower I to remove insoluble impurities therein to obtain clarified brine, which is then sent to the dosing and stirring device, and at first, 5% by mass sodium hydroxide solution is added thereto to adjust the pH ≈ 7-8;

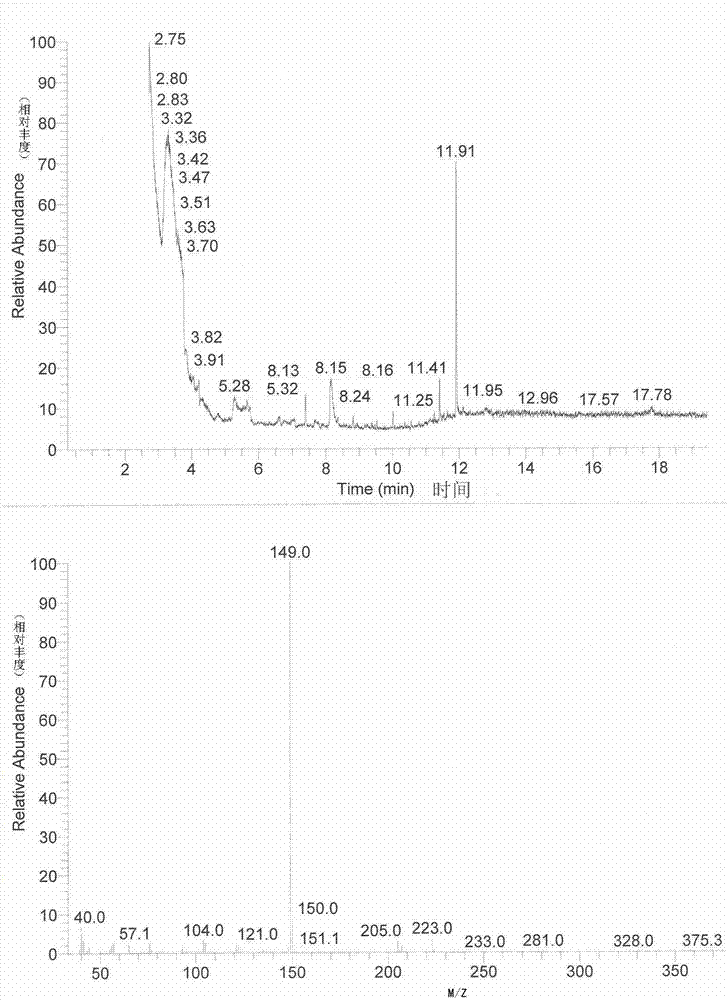

[0030] 2. Using the principle of homogeneous catalytic oxidation, adding the oxidant sodium ferrate (Na 2 FeO 4 ), under the catalysis of the catalyst sodium iodate, the small molecule organic acid that causes the brine odor is completely oxidized and decomposed into carbon dioxide, and then 5% by mass of sodium carbonate coprecipitant is added to it, and after a period of stirring, the resulting MgCO 3 , CaCO 3 and Fe(OH) 3 Co-precipitation is formed, and then sent to the inclined tube sedimentation tank for precipitation, and there is obvious stratification in the inclined tube sedimentation tank.

[0031] 3. The slurry in the lower layer is sent to the plate and frame filter press to filter out the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com