Method for recycling leftover and waste materials of phenolic fireproof insulation board

A technology for fireproof insulation boards and waste materials, applied in the field of foam insulation materials, can solve the problems of high brittleness, application limitation, easy powdering and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0013] A preparation method of expandable phenolic resin, comprising the following steps:

[0014] Add 1 mol of phenol and 1.2-1.8 mol of formaldehyde into a three-necked flask equipped with a stirrer, a thermometer and a reflux condenser, turn on reflux heating, and start stirring; when the reaction liquid is 40°C, use 30% KOH aqueous solution to adjust the pH value to 8-9; heat up and control the reaction at 80°C-90°C for 90 minutes; adjust the pH value to 6.5-8.5 with acid, and then dehydrate under reduced pressure at 70°C until cooled to room temperature to obtain expandable phenolic resin.

[0015] The preparation method of filler among the present invention:

[0016] Grind the corners and waste materials of the collected phenolic resin insulation board into fine powder with a pulverizer.

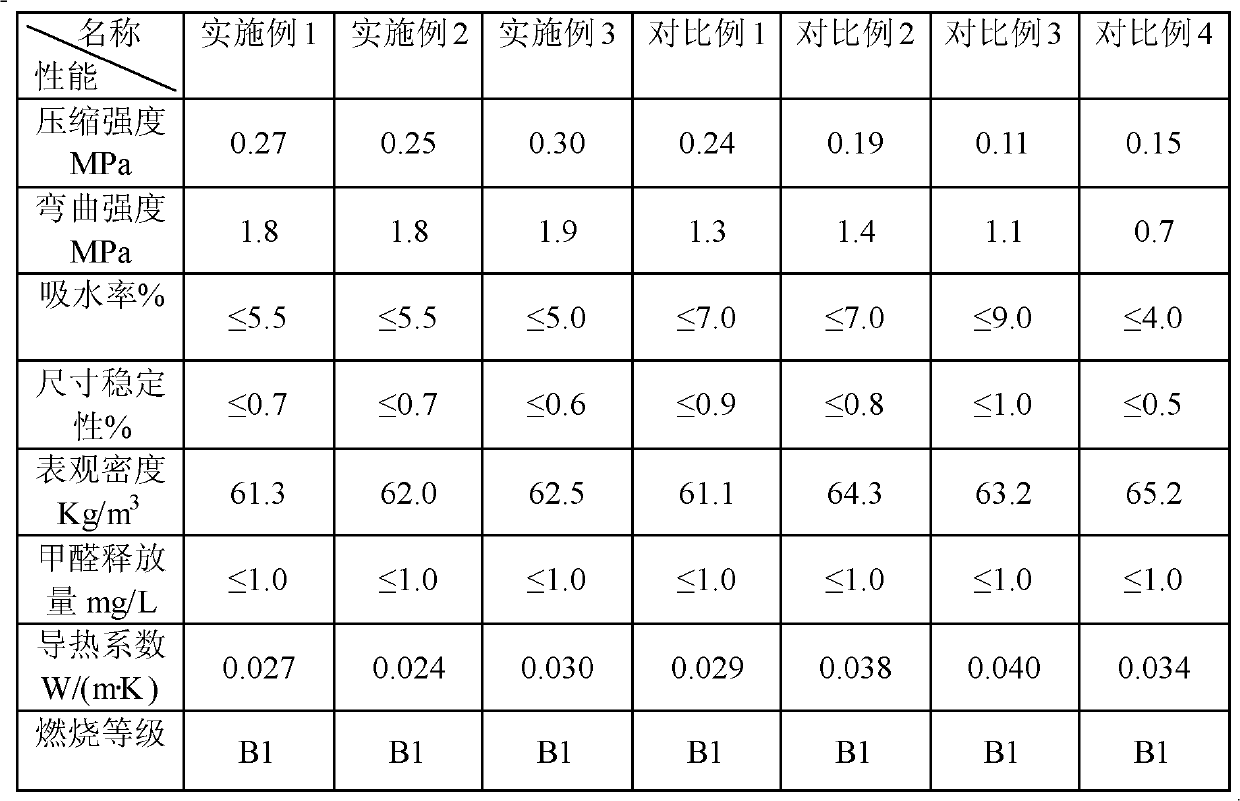

Embodiment 1

[0018] Add 100 parts by weight of resin to the corners of the phenolic resin insulation board, 10 parts by weight of waste materials, 10 parts by weight of polyurethane prepolymer 1#, 4 parts by weight of surfactant H-208, 8 parts by weight of n-pentane, curing agent 18 parts by weight, uniformly stirred in an environment of 20-30° C., and cured at 70° C. to prepare phenolic foam A, whose performance indicators are listed in Table 1.

Embodiment 2

[0020] Add 100 parts by weight of resin to the corners of the phenolic resin insulation board, 15 parts by weight of waste materials, 15 parts by weight of polyurethane prepolymer 1#, 5 parts by weight of surfactant H-208, 10 parts by weight of n-pentane, curing agent 20 parts by weight, uniformly stirred under the environment of 20-30°C, and cured at 70°C to prepare phenolic foam B, whose performance index is shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com