A checker brick hot stove grate board device

A technology of checker bricks and hot blast stoves, applied in furnaces, blast furnaces, heating furnaces, etc., can solve the problems of no substantial improvement and complex rib structure, and achieve the goal of increasing the area, improving the effective utilization factor, and improving the uniformity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

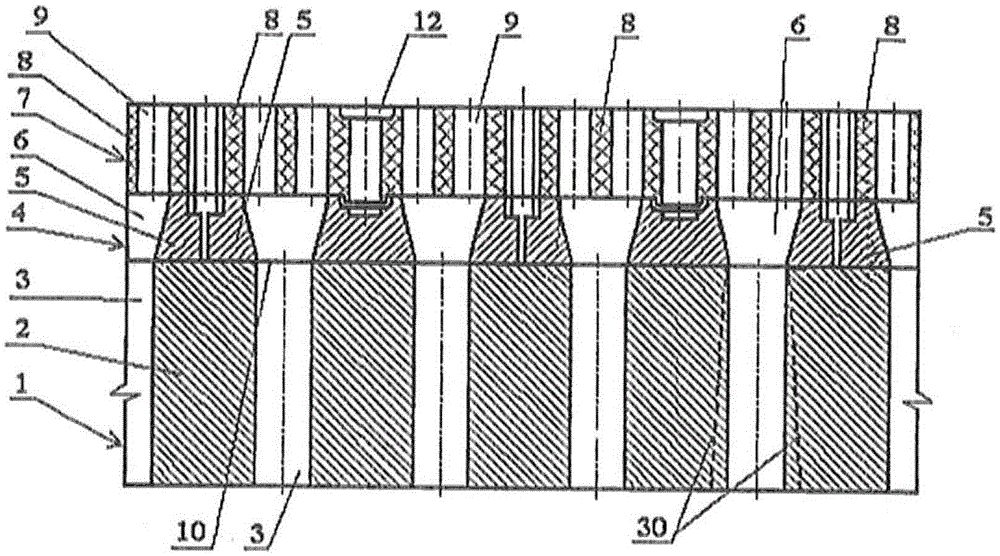

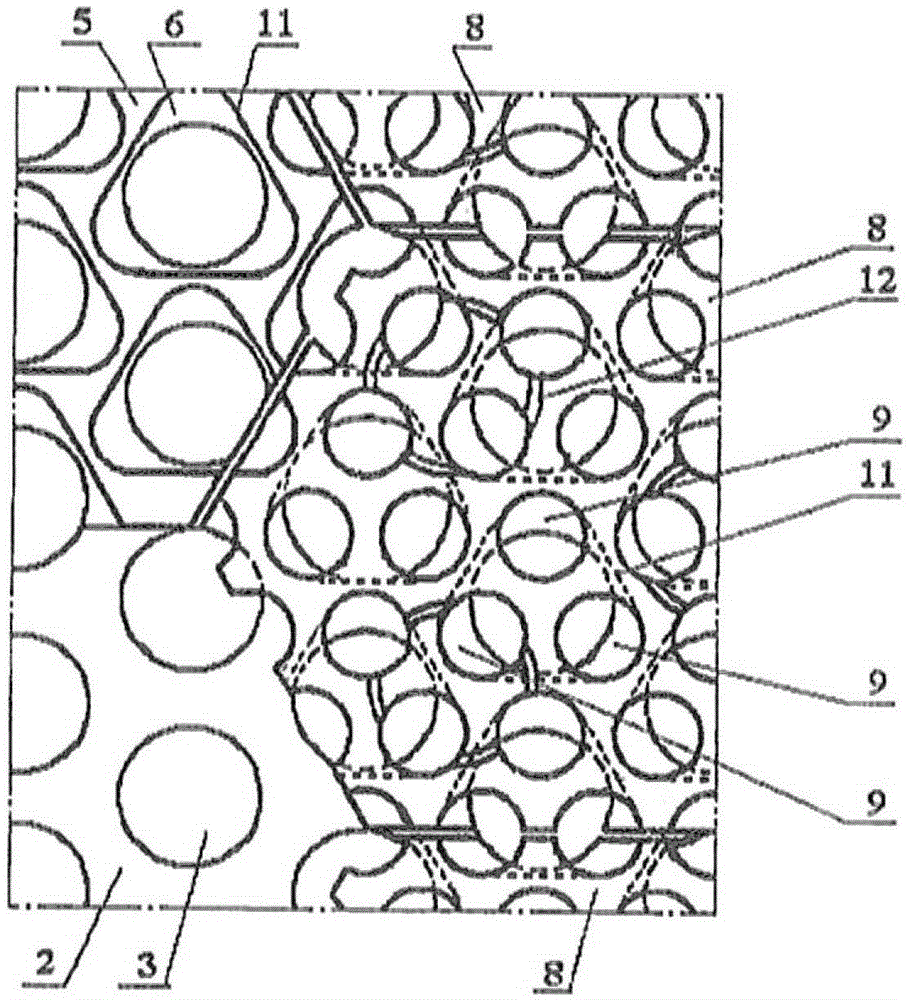

[0024] figure 1 and figure 2 Shown is a first embodiment of a grate assembly including a flat splitter and support grate assembly. The grate device includes a horizontal layer 1 formed by supporting the grate assembly 2, and the support grate assembly 2 has a cylindrical vertical transparent hole 3 (with a vertical partition). A horizontal layer 4 composed of a flat splitter plate 5 is arranged on the supporting grate assembly 2 , and has a transparent hole 6 . A horizontal layer 7 composed of checker brick components 8 is arranged on the flat splitter plate 5 , and the checker bricks have transparent cylindrical holes 9 .

[0025] The through hole 6 of the flat splitter plate 5 is in the form of upward expansion ( figure 1 ), the lower cylindrical window 10 of each eyelet 6 is in contact with the cylindrical transparent eyelet 3 supporting the grate sub-board assembly 2. The transparent hole 3 supporting the grate plate assembly 2 is cylindrical and has a vertical partit...

Embodiment 2

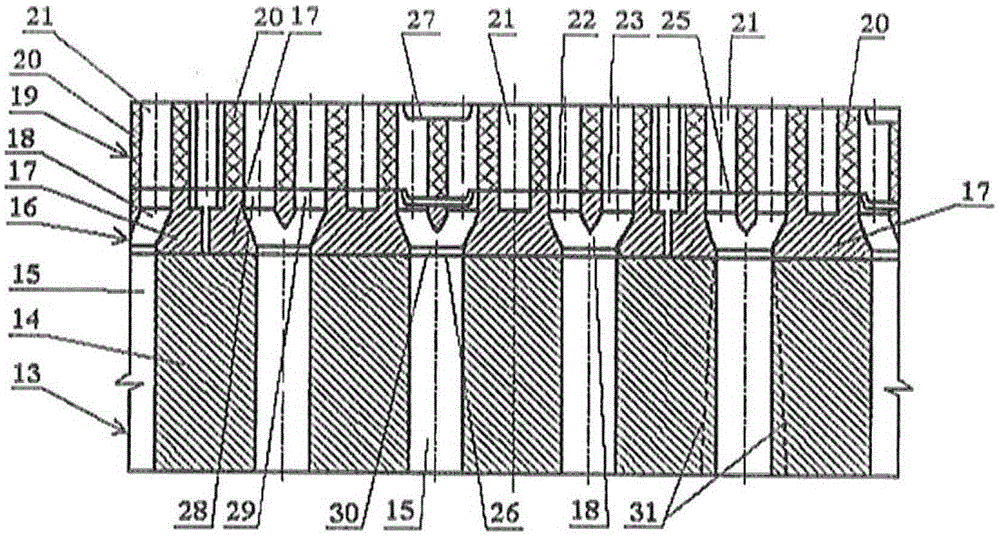

[0028] Figure 3-5 A second embodiment of the invention is shown, the grate assembly comprising a horizontal layer 13 supporting a grate assembly 14 with cylindrical through holes 15 . Supporting structures are not shown on these figures. A horizontal layer 16 formed by a flat splitter plate 17 with through holes 18 is arranged above the supporting grate sub-board assembly 14 . Above the flat splitter plate 17 is first placed a horizontal layer 19 of checker brick assemblies 20 with vertical cylindrical through-holes 21 . Each perforation 18 on the flat splitter plate 17 is made up of three cylindrical, mutually adjacent channels 22, 23, 24 that diverge upward (downward contraction, pouring down), and each of said channels is flattened. There is a window 25 on the upper surface of the splitter plate 17, which is in contact with the through hole 21 of the checker brick assembly 20. Three mutually adjacent channels 22 , 23 , 24 in each through hole 18 of the splitter plate 16...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com