Method for preparing high-speed steel coating by carrying out laser cladding on surface of spheroidal graphite cast iron

A nodular cast iron and laser cladding technology, applied in the field of materials, can solve the problems of comprehensive wear, easy stress, and roll failure, and achieve the effects of prolonging service life, small machining allowance, and accurate control of coating thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Use acetone to remove the oil stain on the surface of the ductile iron, use No. 400 sandpaper to polish the surface of the ductile iron to remove the rust layer, and then use absolute ethanol to clean the surface of the ductile iron;

[0037] Prepare V10 high-speed steel powder, its composition contains C2.4%, Cr5.5%, Mo1.3%, V10.5% by weight percentage, the balance is Fe, particle size≤44μm;

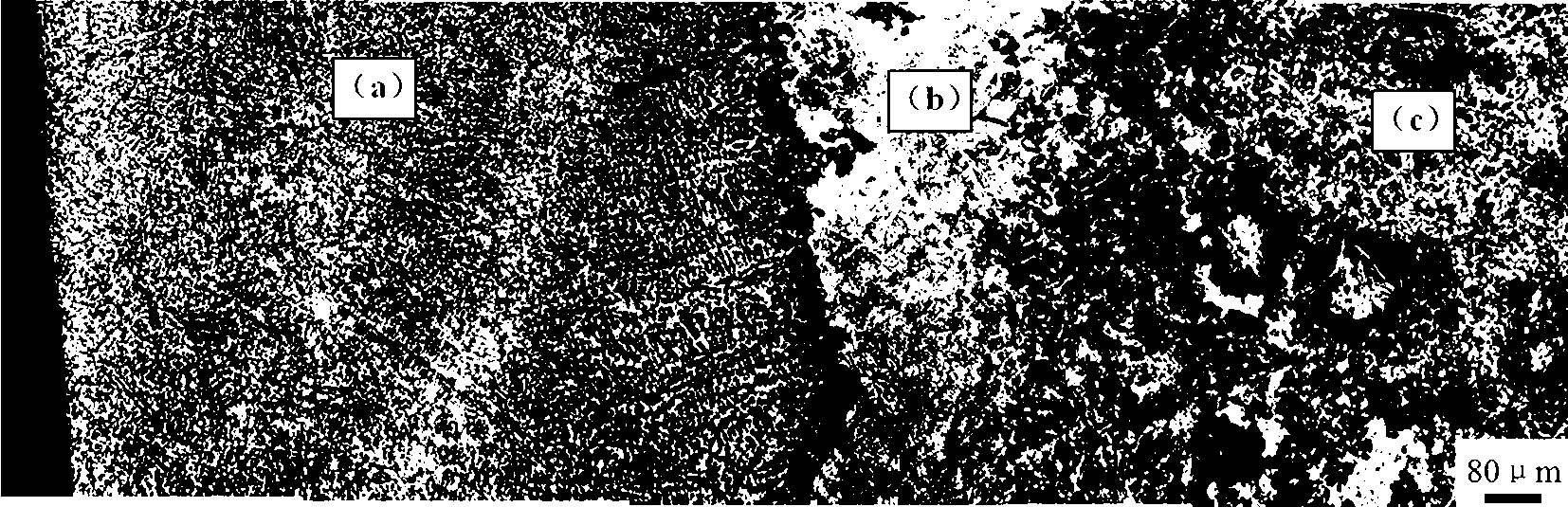

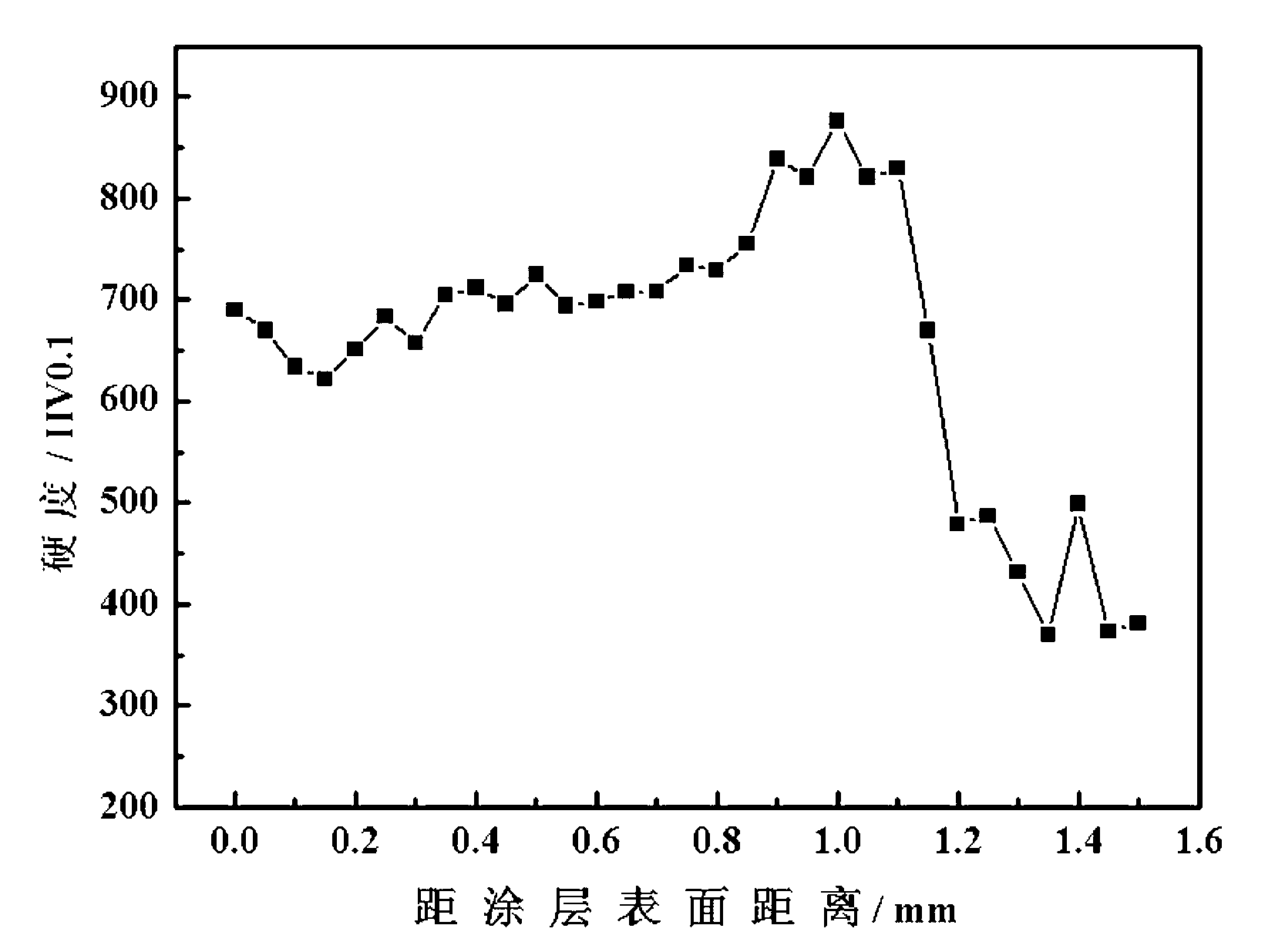

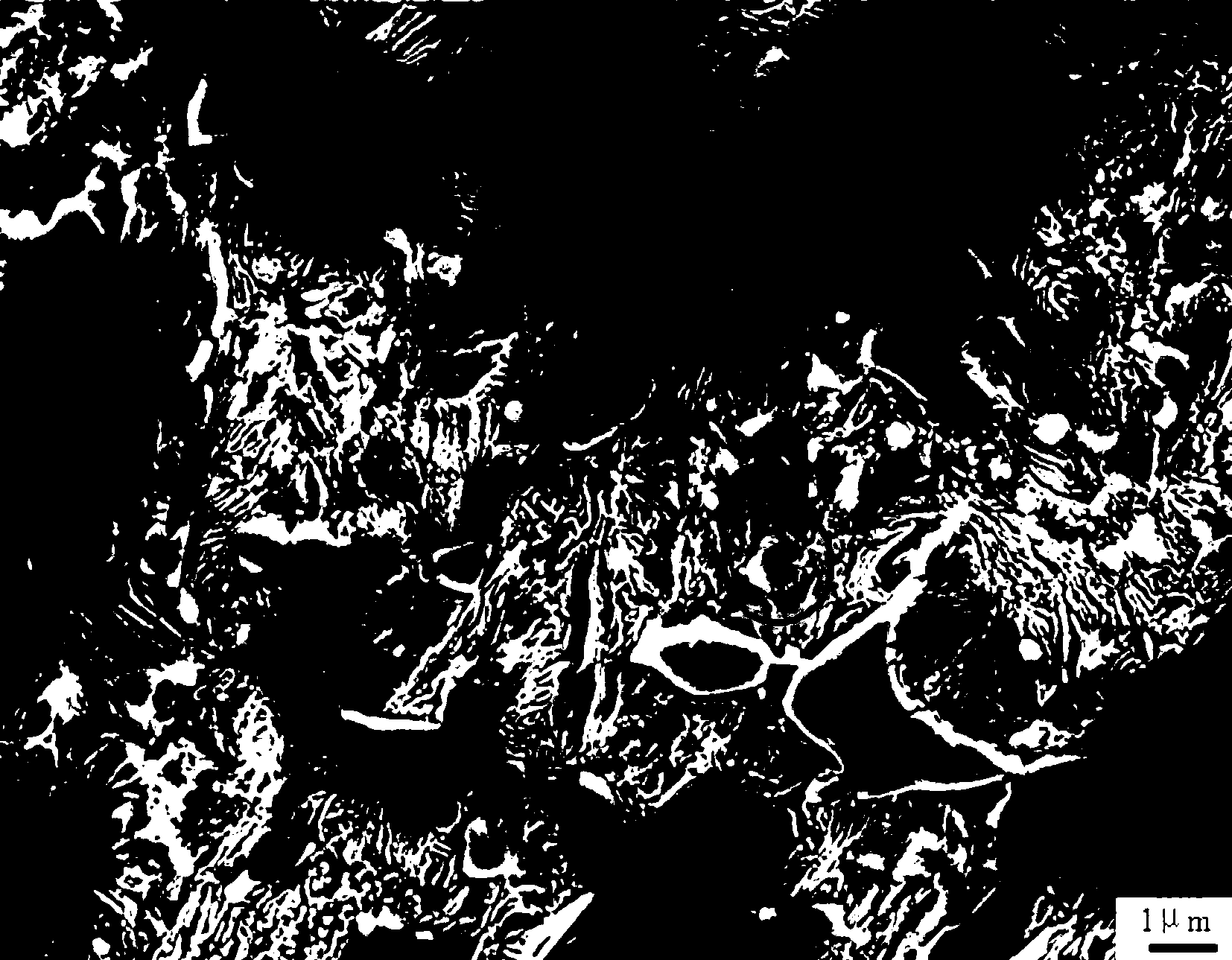

[0038]Laser cladding treatment is carried out on the surface of nodular cast iron by using a semiconductor laser, and the high-speed steel powder is preset on the surface of the nodular cast iron. At the same time, the surface of the nodular cast iron is irradiated with laser to melt the high-speed steel powder and the surface of the nodular cast iron to control the laser cladding. The power is 2300W, the scanning speed is 10mm / s, the laser is focused, and the spot is a rectangular spot with a length of 11.5mm and a width of 2.5mm; the thickness of the preset high-speed steel powd...

Embodiment 2

[0042] The method for removing oil stains and rust layers on the surface of ductile iron and cleaning the surface of ductile iron is the same as in Example 1;

[0043] Prepare V10 high-speed steel powder, its composition contains C2.5%, Cr5.3%, Mo1.0%, V10% by weight percentage, the balance is Fe, particle size≤44μm;

[0044] Laser cladding treatment is carried out on the surface of ductile iron by semiconductor laser, the high-speed steel powder is preset on the surface of ductile iron, and the surface of ductile iron is irradiated with laser to melt the high-speed steel powder and the surface of ductile iron, and the power of laser cladding is controlled It is 1800W, the scanning speed is 6mm / s, the laser is focused, and the spot is a rectangular spot with a length of 8mm and a width of 1mm; the thickness of the preset high-speed steel powder is 0.5mm, and the overlap rate is 50%; after the laser cladding is completed, the The surface of the ductile iron is coated with high-...

Embodiment 3

[0046] The method for removing oil stains and rust layers on the surface of ductile iron and cleaning the surface of ductile iron is the same as in Example 1;

[0047] Prepare V10 high-speed steel powder, the composition of which contains C2.4%, Cr5%, Mo0.5%, V9.5% by weight percentage, the balance is Fe, and the particle size is ≤44μm;

[0048] Laser cladding treatment is carried out on the surface of ductile iron by semiconductor laser, the high-speed steel powder is preset on the surface of ductile iron, and the surface of ductile iron is irradiated with laser to melt the high-speed steel powder and the surface of ductile iron, and the power of laser cladding is controlled The laser is 3000W, the scanning speed is 8mm / s, the laser is focused, and the spot is a rectangular spot with a length of 10mm and a width of 2mm; the thickness of the high-speed steel powder is 1.5mm, and the overlap rate is 60%; after the laser cladding is completed, the surface of the ductile iron The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com