Method for electrolyzing high-content low-grade lead bullion

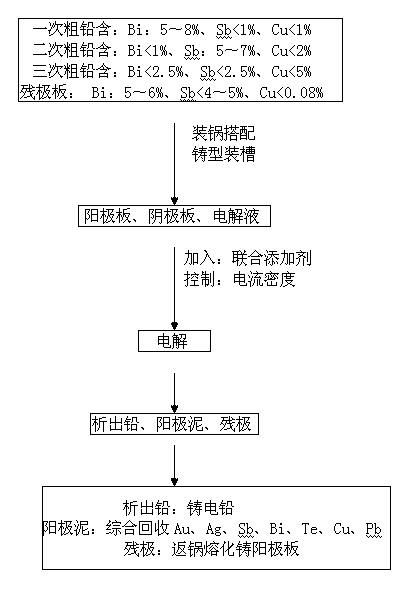

An electrolysis method and low-grade technology, applied in the improvement of process efficiency, photography technology, instruments, etc., can solve the problems affecting industrial production, the grade of precipitated lead cannot meet the requirements of the national standard, and the crude lead cannot meet the production needs. The effect of improving the grade of metal content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Example 1: Contain copper, antimony, bismuth and other high-rich and low-grade crude lead, melt and stir in a pot to remove copper, remove copper-containing scum, add alkali to make slag to remove arsenic and tin, measure the temperature of the lead liquid, and control At 420 ℃ ~ 450 ℃, the lead liquid is poured into the anode plate casting machine through the lead pump to cast the anode plate. The metal grades of the anode plate are: Pb: 88.05%, Ag: 2653g / t, Au: 2g / t, Cu : 0.11%, Bi: 5.93%, Sn: 0.14%, Sb: 4.66%, As: 0.83%; put the anode plate into the electrolytic cell for 72h electrolysis, the cathode lead is taken out of the water, and the precipitated lead and lead metals are precipitated The grades are: Pb: 99.96258%, Ag: 0.00008%, Cu: 0.00022%, Bi: 0.00274%, Sn: 0.00574%, Sb: 0.02826%, As: 0.00021%, Fe: 0.00011%; At this time, the grades of each metal in the anode slime are: Pb: 17.49%, Ag: 27514g / t, Cu: 1.01%, Bi: 15.83%, Sb: 41.43%, As: 6.73%, Au: 24.54g / t, Te ...

Embodiment 2

[0025] Example 2: Use high-rich and low-grade crude lead containing copper, antimony, bismuth, etc., to melt and stir in a pot to remove copper, remove copper-containing scum, add alkali to make slag to remove arsenic and tin, measure the temperature of molten lead, and control At 420 ℃ ~ 450 ℃, the lead liquid is poured into the anode plate casting machine through the lead pump to cast the anode plate. The metal grades of the anode plate are: Pb: 88.05%, Ag: 2750g / t, Au: 2g / t, Cu : 0.08%, Bi: 4.85%, Sn: 0.05%, Sb: 5.66%, As: 1.02%; put the anode plate into the electrolytic cell for 72h electrolysis, the cathode lead is taken out of the water, and the precipitated lead and lead metals are precipitated The grades are: Pb: 99.97738%, Ag: 0.00004%, Cu: 0.00022%, Bi: 0.00119%, Sn: 0.00451%, Sb: 0.01636%, As: 0.00015%, Fe: 0.00012%; At this time, the grades of each metal in the anode slime are: Pb: 18.07%, Ag: 27684g / t, Cu: 1.08%, Bi: 16.06%, Sb: 41.89%, As: 7.1%, Au: 24.68g / t, Te ...

Embodiment 3

[0026]Example 3: Contain copper, antimony, bismuth and other high-rich and low-grade crude lead, melt and stir in a pot to remove copper, remove copper-containing scum, add alkali to make slag to remove arsenic and tin, measure the temperature of molten lead, and control At 420 ℃ ~ 450 ℃, the lead liquid is poured into the anode plate casting machine through the lead pump to cast the anode plate. The metal grades of the anode plate are: Pb: 88.8%, Ag: 2785g / t, Au: 2g / t, Cu : 0.07%, Bi: 5.12%, Sn: 0.21%, Sb: 4.65%, As: 0.86%; put the anode plate in the electrolytic cell for 72h electrolysis, the cathode lead is taken out of the water, and the precipitated lead and lead metals are precipitated The grades are: Pb: 99.96525%, Ag: 0.00003%, Cu: 0.00012%, Bi: 0.00391%, Sn: 0.00522%, Sb: 0.02514%, As: 0.00018%, Fe: 0.00012%; At this time, the grades of each metal in the anode slime are: Pb: 17.16%, Ag: 27172g / t, Cu: 0.92%, Bi: 16.56%, Sb: 41.85%, As: 7.37%, Au: 23.78g / t, Te : 0.13%....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com