Drilling Rig Measurement While Drilling System

A measurement-while-drilling, drilling rig technology, which is applied in the measurement, drilling automatic control system, drilling equipment and other directions The effect of reliability and accuracy, accurate and reliable data, and high modularity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

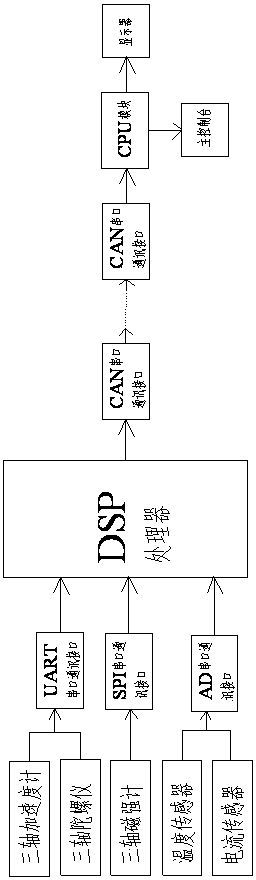

[0014] Such as figure 1 As shown, the rig-while-drilling measurement system of the present invention includes a sensor module, a signal bar, a CPU module and a display, and the sensor module includes a three-axis accelerometer, a three-axis gyroscope, a three-axis magnetometer, a temperature sensor and a current sensor, The three-axis accelerometer and the three-axis gyroscope are provided with a UART serial communication interface, the three-axis magnetometer is provided with an SPI serial communication interface, and the temperature sensor and the current sensor are provided with an AD serial communication interface; The signal bar includes a DSP processor and a power module. The core chip TMS320F28335 of the DSP processor has a powerful floating-point number processing capability, and the operation speed is as high as 150MHz. The DSP processor includes a power interface connected to the power module and a sensor The communication interface module connected with the modules,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com