Pin hole output adjustable backlash planetary gear with less tooth difference

A planetary and transmission technology with less tooth difference, applied in the direction of gear transmission, transmission, transmission parts, etc., can solve the problems of single mechanism, high manufacturing cost, complex structure, etc., to eliminate gaps, improve bearing capacity and use Longevity and the effect of improving transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing and embodiment;

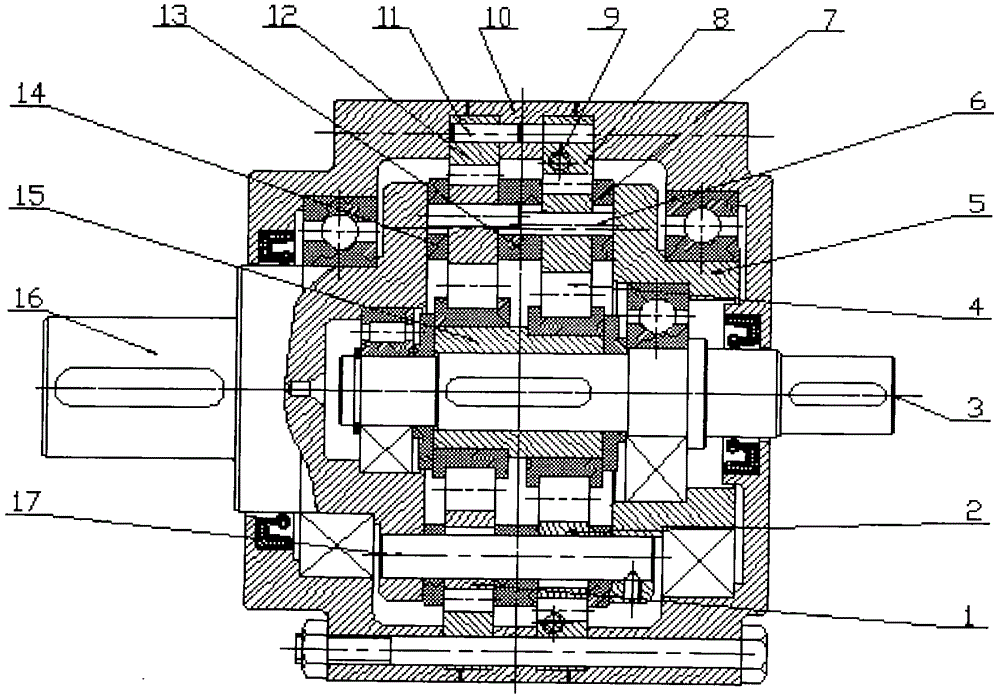

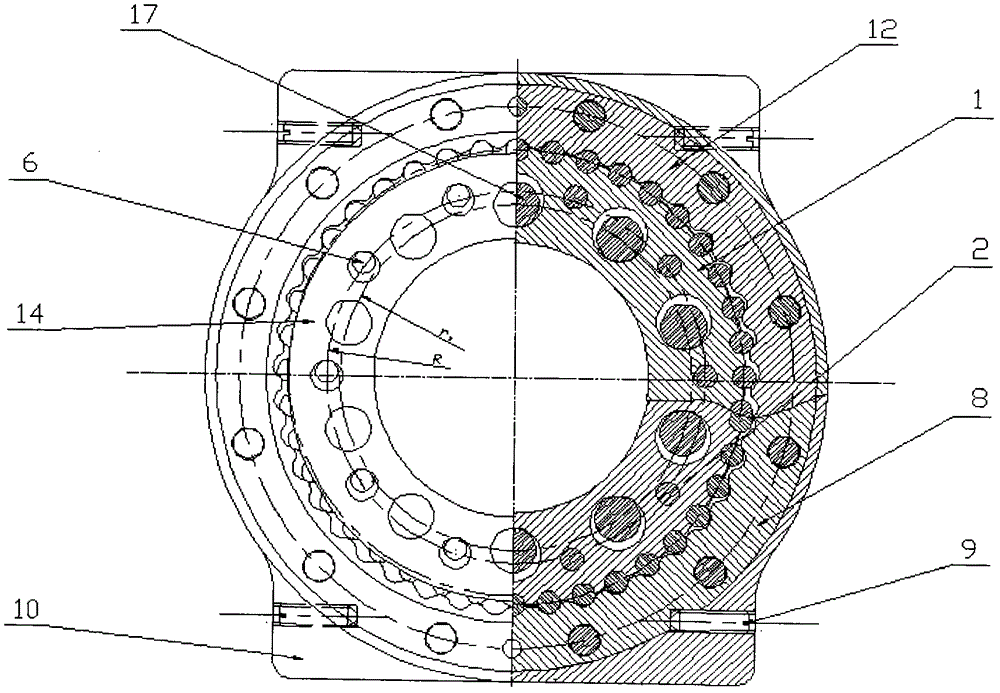

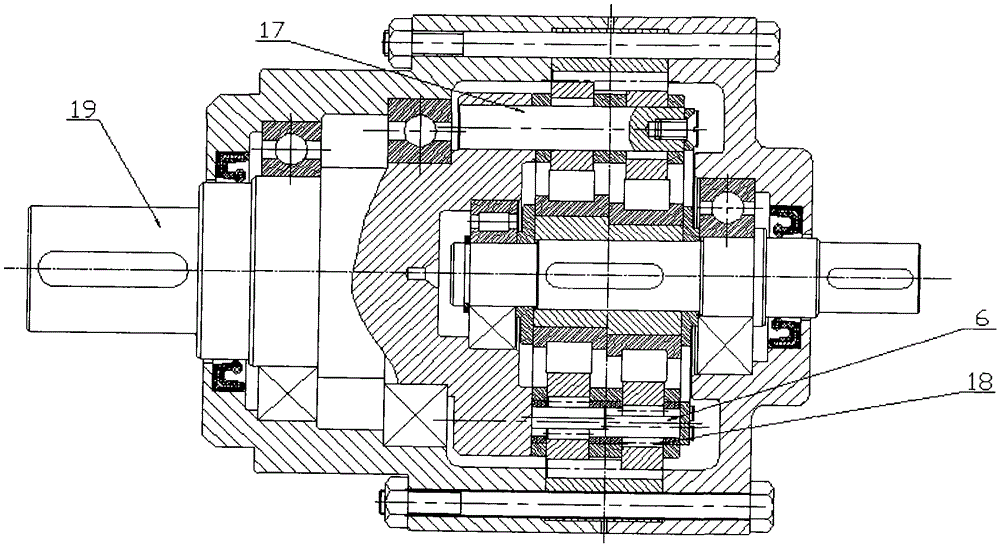

[0018] Such as figure 1 As shown, the transmission device is input with a high angular velocity from the input shaft 3, through the double eccentric sleeve 15 and the arm bearing 4 with a phase difference of 180°, the right planetary gear 2 and the left planetary gear 1 are installed respectively with the The right center wheel 8 and the left center wheel 12 mesh, so that the right planetary wheel 2 and the left planetary wheel 1 obtain low angular velocity. Insert the right power transmission disc 7, the middle power transmission disc 13 and the left power transmission disc 14 fixed on the output shaft dowel rod 17 on both sides through the power transmission pin 6 mounted on the right planetary wheel 2 and the left planetary wheel 1 respectively. Corresponding to the hole, the output of the low angular velocity constant speed ratio. The output shaft of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com