Ultrasonic detection device and method for pipeline leakage

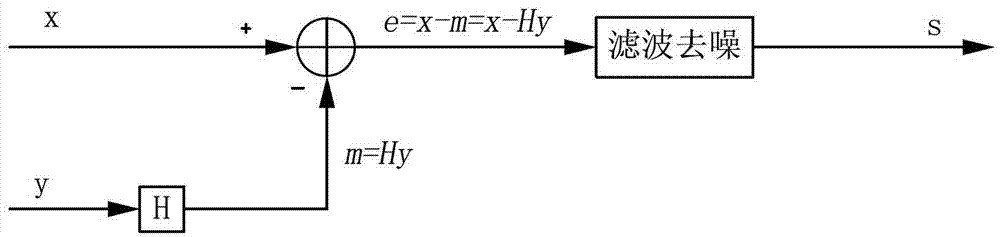

A technology of pipeline leakage and detection device, which is applied in pipeline systems, mechanical equipment, gas/liquid distribution and storage, etc., can solve the problem of inability to detect leakage of pipeline joints, and achieves prevention of man-made or normal leakage accidents, high detection accuracy, and improved detection. The effect of the signal-to-noise ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

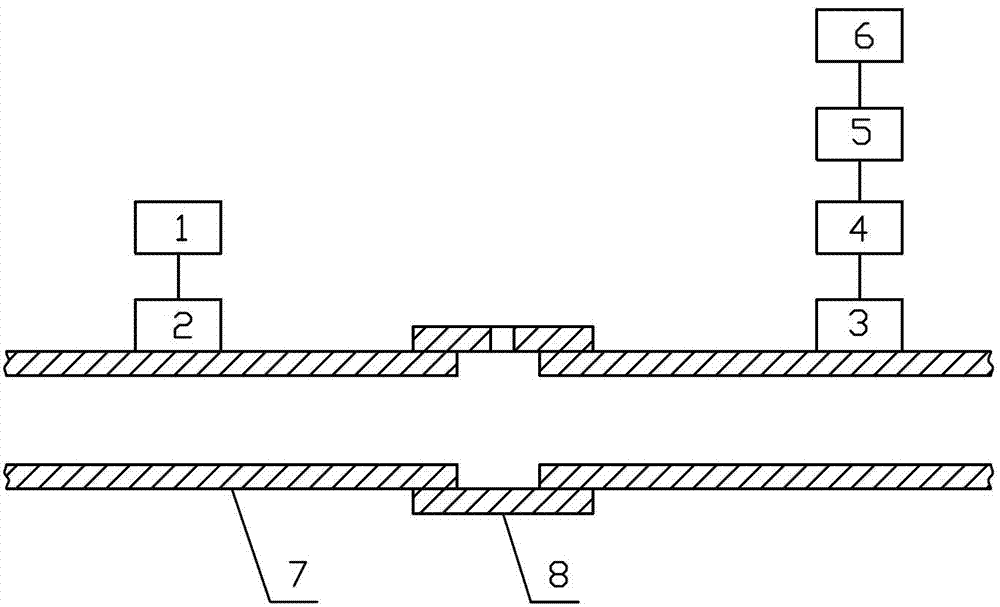

[0036] Such as figure 1 As shown, the ultrasonic detection device for pipeline leakage in this embodiment is composed of a signal generator 1 , a transmitting ultrasonic transducer 2 , a receiving ultrasonic transducer 3 , a preamplifier 4 , a signal collector 5 and a computer 6 .

[0037] The transmitting ultrasonic transducer 2 of this embodiment is installed on one side of the oil pipeline joint, the receiving ultrasonic transducer 3 is installed on the other side of the oil pipeline joint, and the transmitting ultrasonic transducer 2 passes through the coaxial The cable is connected to the signal generator 1, receives the electrical signal generated by the signal generator 1, and converts it into an acoustic signal and transmits it along the oil pipeline, receives it by the receiving ultrasonic transducer 3, and converts it into an electrical signal output, and receives the ultrasonic transducer The output end of device 3 is connected with the input end of preamplifier 4 b...

Embodiment 2

[0056] The structure of the ultrasonic detection device for pipeline leakage in this embodiment is the same as that in Embodiment 1.

[0057] In the method for ultrasonic detection of oil pipeline joint leakage by using the detection device, step (1) is that the signal generator 1 sends out a rectangular pulse electrical signal with a power of 10W, a frequency of 1MHz, and a pulse width of half the signal period. Step (2) is that the above-mentioned rectangular pulse electrical signal is transmitted to the transmitting ultrasonic transducer 2 through the coaxial cable, and the transmitting ultrasonic transducer 2 converts the received rectangular pulse electrical signal into an ultrasonic signal for transmission along the oil pipeline; The transducer is a commercially available common piezoelectric ultrasonic transducer with a frequency of 1 MHz and a bandwidth of 30% of its center frequency. Step (4) is for the preamplifier 4 to amplify the received electrical signal, the gai...

Embodiment 3

[0060] The structure of the ultrasonic detection device for pipeline leakage in this embodiment is the same as that in Embodiment 1.

[0061] In the method for ultrasonic detection of oil pipeline joint leakage by using the detection device, step (1) is that the signal generator 1 sends out a rectangular pulse electrical signal with a power of 50W, a frequency of 5MHz, and a pulse width of half the signal period. Step (2) The above-mentioned rectangular pulse electrical signal is transmitted to the transmitting ultrasonic transducer 2 through the coaxial cable, and the transmitting ultrasonic transducer 2 converts the received rectangular pulse electrical signal into an ultrasonic signal for transmission along the oil pipeline; the transducer It is a commercially available common piezoelectric ultrasonic transducer with a frequency of 5 MHz and a bandwidth of 60% of its center frequency. Step (4) is for the preamplifier 4 to amplify the received electrical signal, the gain of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com