Mobile car automatic loading and weighing system

A technology of automatic loading and weighing system, applied in the direction of detailed information of weighing equipment, weighing, measuring devices, etc., can solve the problems of conveying device failure, high manufacturing cost, large installation space, etc. Low cost and the effect of improving the life of the whole machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

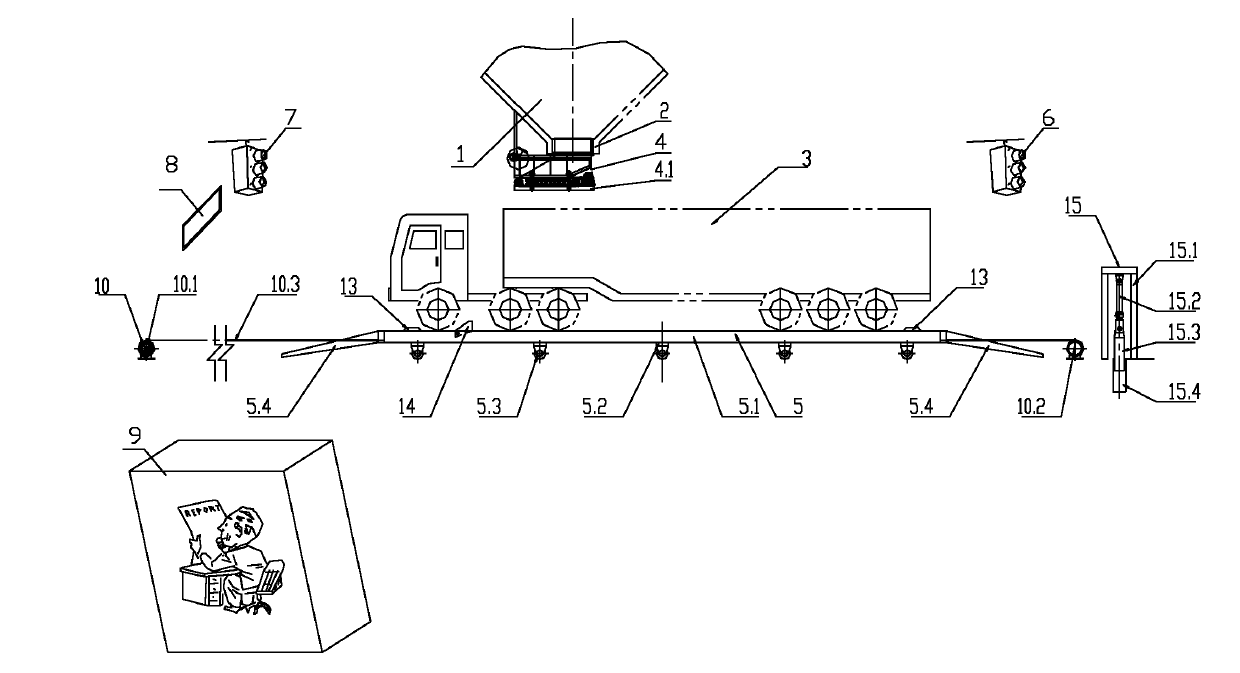

[0069] figure 1 It is the mobile vehicle automatic loading and weighing system described in this embodiment. The mobile vehicle automatic loading and weighing system includes a feed bin 1, a mobile vehicle loading automatic weighing device, a feeding device, a control device and an auxiliary device, and the feeding device is set At the outlet of the silo 1, the feeding end of the feeding device is fixedly connected or flexibly connected with the silo 1, and the discharging end of the feeding device is on the upper part of the car facing the trunk of the car, and the mobile car is loaded with an automatic weighing device. Set below the feeding device. The feeding device described in this embodiment is a belt feeder 4.1, and the belt feeder 4.1 can be connected to a car for loading. In order to control the loading speed, a frequency converter can be used to adjust the linear speed of the conveyor belt To effectively control the progress of loading. The mobile vehicle loading a...

Embodiment 2

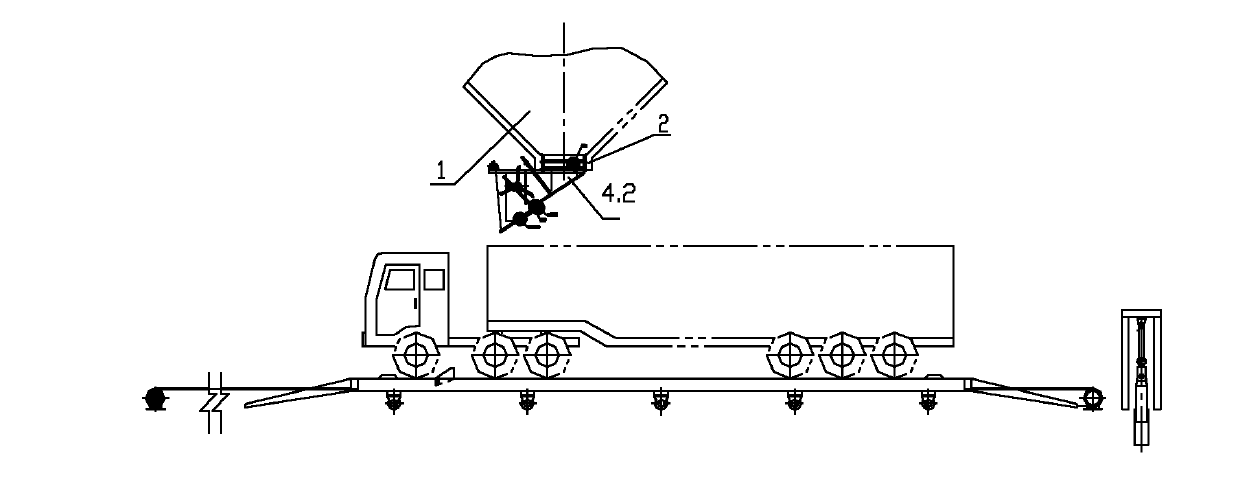

[0075] Such as figure 2 As shown, the feeder 4 can also be a feeder 4.2 with variable inclination.

[0076] Others are with embodiment 1.

Embodiment 3

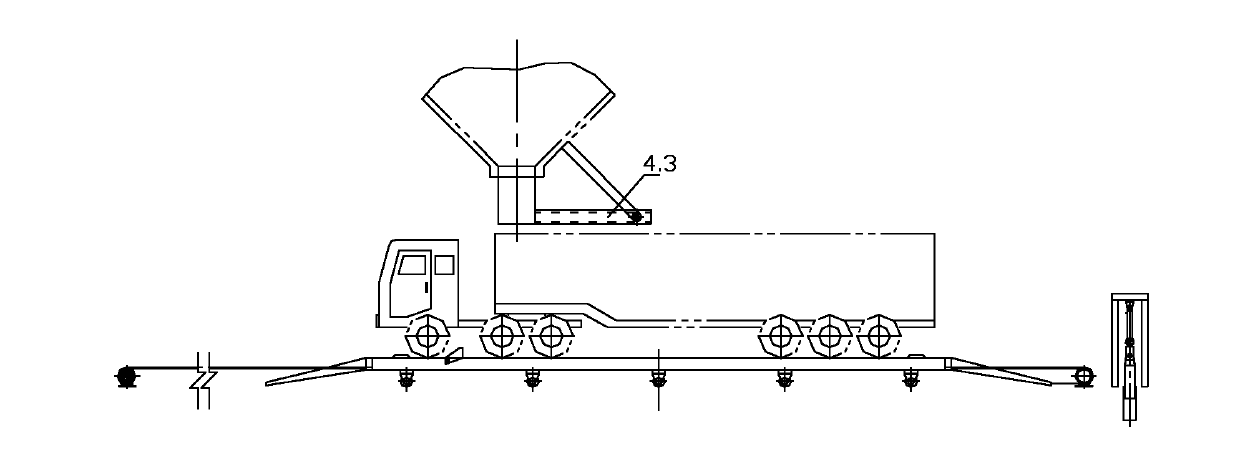

[0078] Such as image 3 As shown, the feeding device can also be a controllable gate 4.3. The controllable gate 4.3 adopts devices such as a flat gate, a sector gate or a controllable chute.

[0079] Others are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com