Stiffened plate structure axial compression stability test clamp and method

A technology of stability test and axial compression, applied in the direction of strength characteristics, measuring devices, instruments, etc., can solve the problems of complicated installation, increased test cost, high processing accuracy requirements, etc., to ensure effectiveness, save test costs, strong The effect of generality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1 Stiffened plate structure axial compression stability test fixture

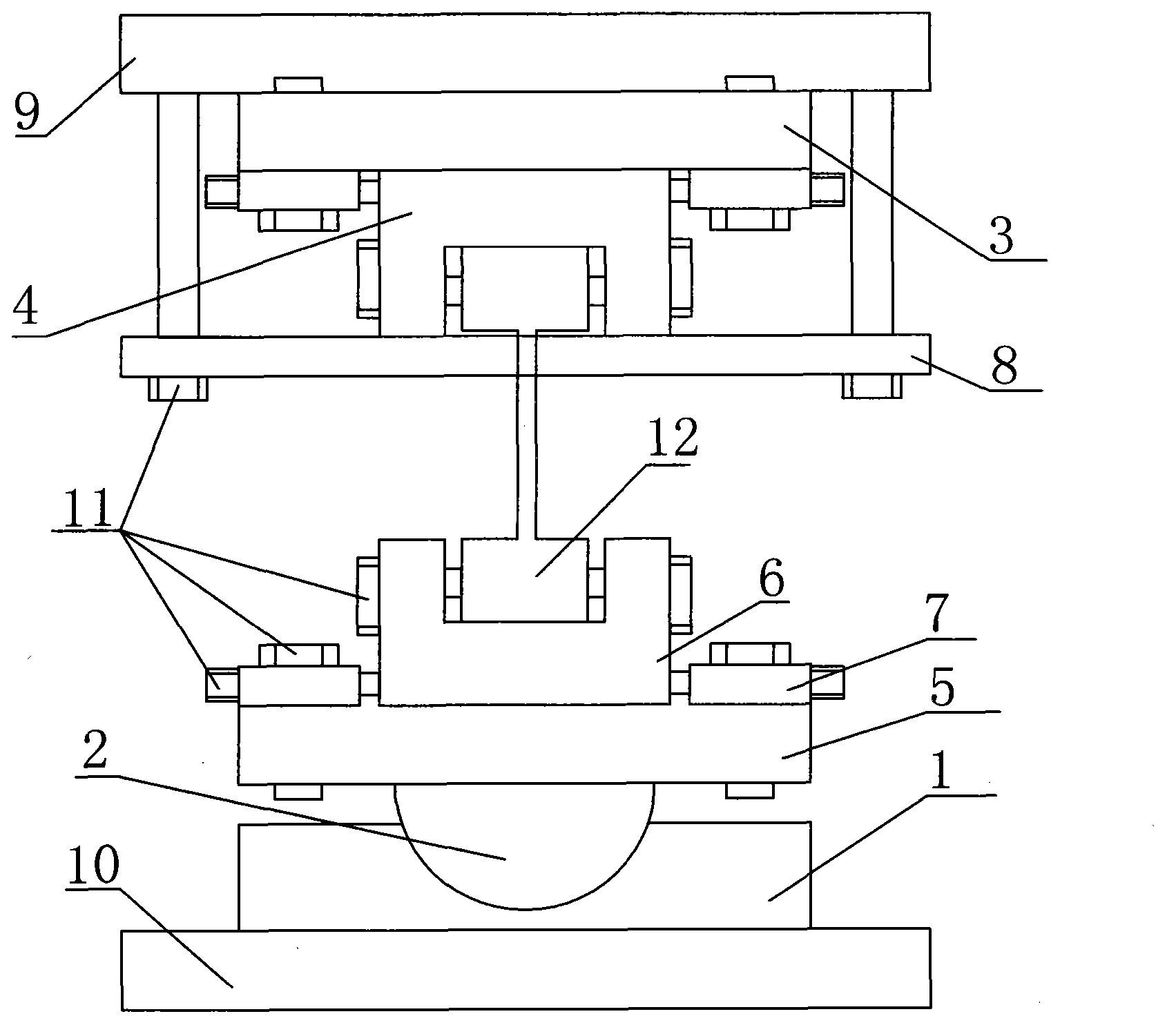

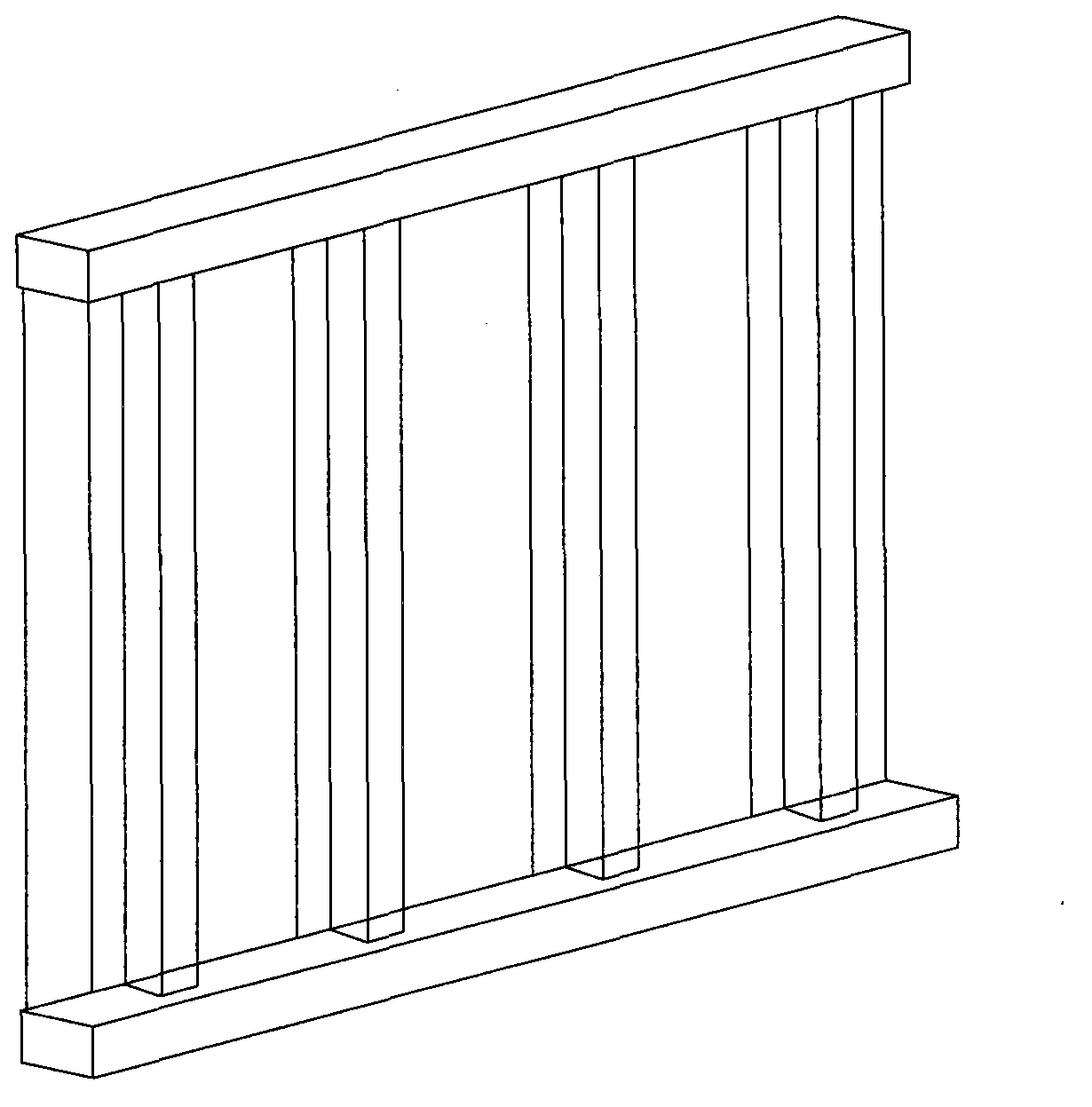

[0042] refer to figure 1 A jig for testing axial compression stability of a stiffened plate structure includes: a semicircular ball seat 1, a semicircular ball head 2 movable in the semicircular ball seat 1, a loading platform and a slot for fixing the end of the test piece, and The stopper that fixes the position of the card slot. During the test, the symmetry and uniformity of the load on the stiffened plate are mainly realized through the self-adaptive movement of the hemispherical head in the hemispherical seat. During installation, the centroid of the fixture is required to be coaxial with the loading center of the testing machine.

[0043] The semicircular ball seat 1 is fixed on the middle position of the lower loading plate 10 of the testing machine, and the lower loading plate 10 is connected with the loading actuator of the testing machine; Apply lubricating oil evenly and pla...

Embodiment 2

[0046] Embodiment 2 Determination and adjustment of test fixture end support coefficient

[0047] The method for determining and adjusting the support coefficient of the loading end applicable to this test fixture includes the following steps:

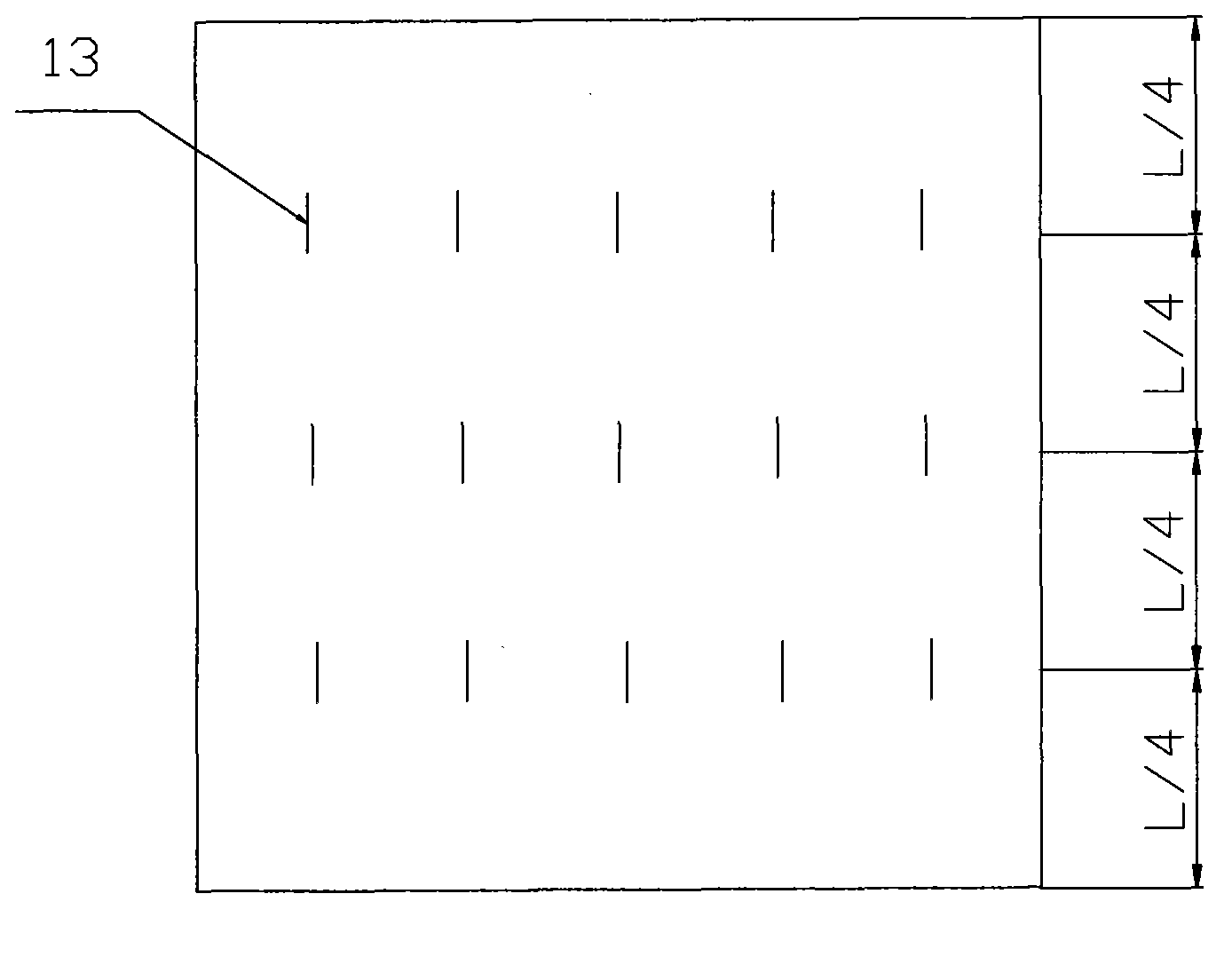

[0048] Step (a): Take a rectangular flat plate with the same length, width, thickness and material properties as the skin of the stiffened plate test piece 12, and symmetrically place it on both sides of the flat plate along the length direction of 1 / 4, 1 / 2, and 3 / 4 The positions are respectively pasted with 13 resistive strain single pieces and 5 pieces each, such as image 3 .

[0049] Step (b): Place the plate in the test fixture of Example 1, place the upper and lower ends of the plate in the upper slot 4 and the lower slot 6 of the fixture respectively, so that the centroid of the flat plate is consistent with the loading center of the testing machine and the centroid of the test fixture Coaxial; to simulate the clamping section...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com