Experimental device for testing heat conductivity coefficient of building material based on quasi steady state and unsteady state methods

An experimental device and building material technology, applied in the direction of material thermal development, etc., can solve the problems of not being able to carry the quasi-steady-state measurement process at the same time, large relative error, long test time, etc., to shorten test preparation time and reduce measurement error , Conducive to the effect of comparison and verification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0009] Embodiment 1: The experimental device for testing the thermal conductivity of building materials based on the quasi-unsteady method described in this embodiment includes an AC regulated power supply 1, a transistor DC regulated power supply 2, a standard resistor 3, at least one heating resistor 4, Low potential potentiometer 5, oil-immersed keyboard switch 6, ice bottle 7 for holding ice-water mixture, first thermocouple 8 (temperature sensing element), second thermocouple 9; AC stabilized power supply 1 and transistor The DC regulated power supply 2 is connected in series with two poles, the positive and negative electrodes of the transistor DC regulated power supply 2 are connected with the electrical connection terminal of at least one heating resistor 4, and the positive electrode of the transistor DC regulated power supply 2 is connected with the current of at least one heating resistor 4. A standard resistance 3 is connected between the input ends; the positive an...

specific Embodiment approach 2

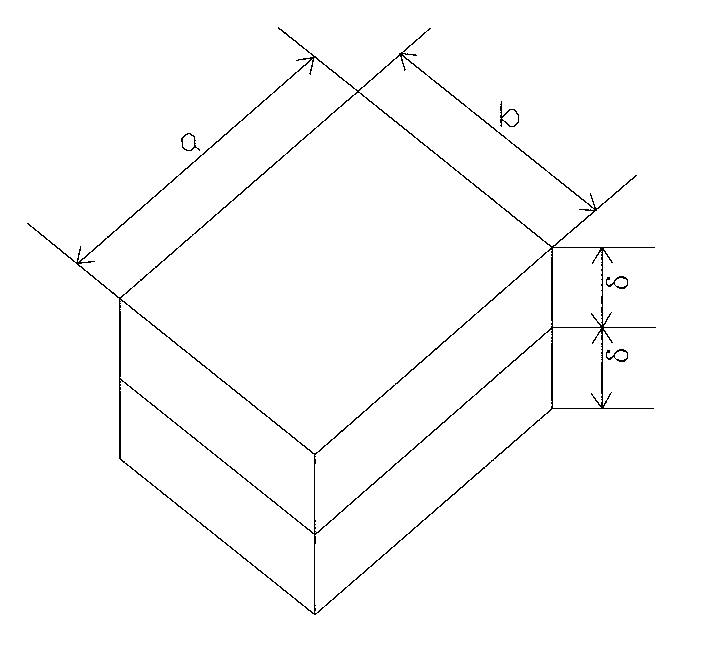

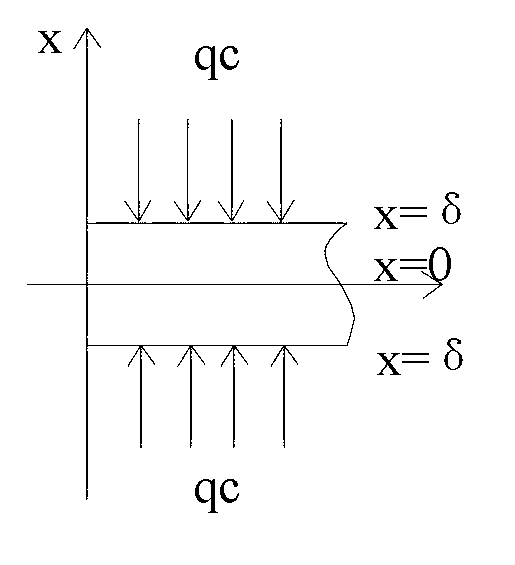

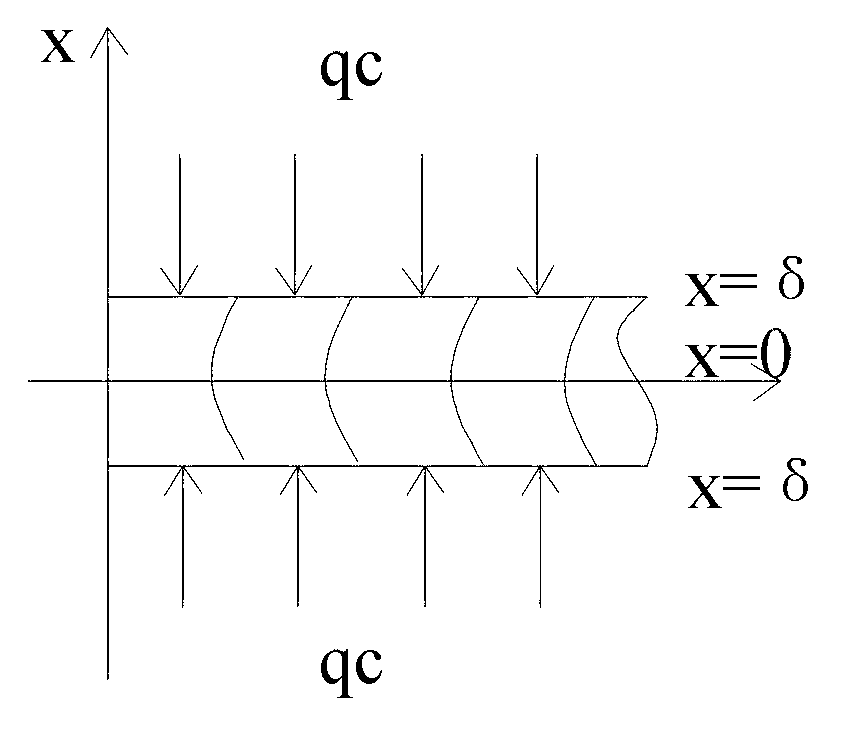

[0010] Specific implementation two: as Figure 4 As shown, the number of heating resistors 4 in the experimental device described in this embodiment is two, and the two heating resistors 4 are connected in parallel on the transistor DC stabilized power supply 2 and the two are arranged in parallel up and down, and the experimental device also includes a plurality of experimental devices. 10 and two thermal insulation layers 11, a plurality of test pieces 10 are composed of a first test piece A1, a second test piece A2, a third test piece A3 and a fourth test piece A4 arranged from top to bottom with the same thickness. The second specimen A2 and the third specimen A3 are located between the two heating resistors 4, the first specimen A1 is placed on the upper heating resistor 4, and the fourth specimen A1 is placed under the lower heating resistor 4 , the first test piece A1, the second test piece A2, the third test piece A3 and the fourth test piece A4 arranged from bottom to...

specific Embodiment approach 3

[0011] Specific implementation three: as Image 6 As shown, the number of heating resistors 4 in the experimental device of this embodiment is one, and the experimental device also includes a plurality of test pieces 10, and the plurality of test pieces 10 are arranged from top to bottom. A test piece I and a third test piece III are composed, the first test piece I is located above the heating resistor 4, and the measurement end of the first thermocouple 8 and the measurement end of the second thermocouple 9 are respectively located on the upper and lower sides of the first test piece I On both sides, the thickness of the second test piece II and the third test piece III is greater than the thickness of the first test piece I. Other components and connection relationships are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistance | aaaaa | aaaaa |

| Resistance | aaaaa | aaaaa |

| Wire diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com