Control device and method for starting and stopping oxyhydrogen decarbonizing machine

A start-stop control, hydrogen-oxygen technology, applied in sequence/logic controller program control, electrical program control, etc. The effect of stable and reliable signal, reliable function and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

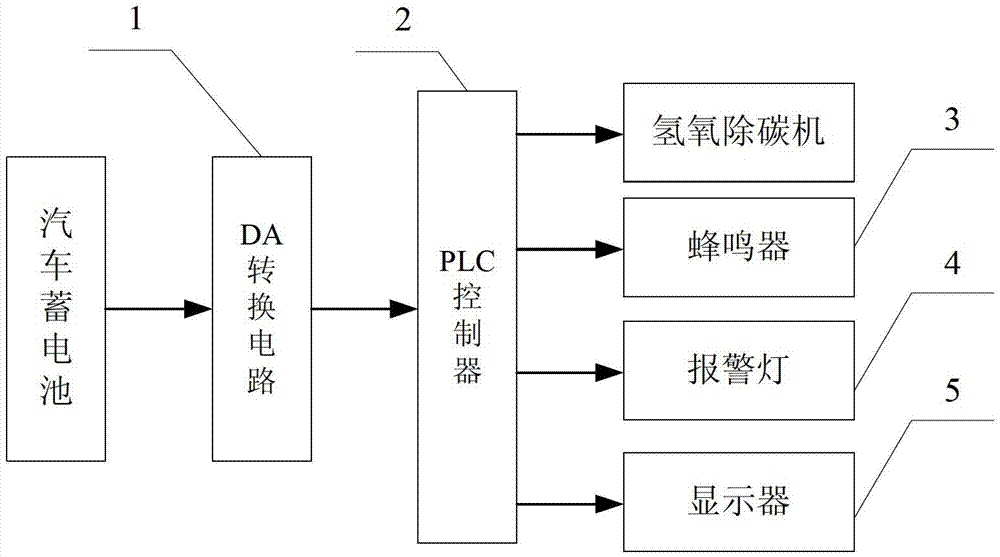

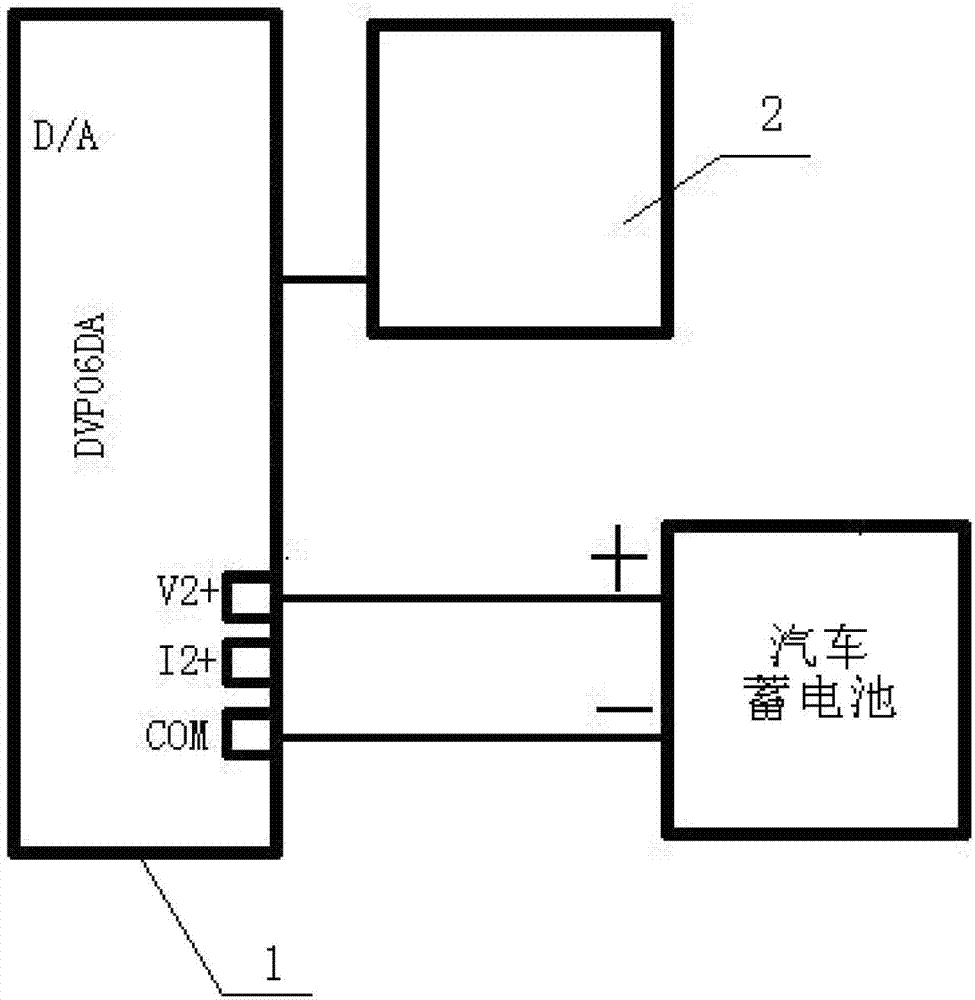

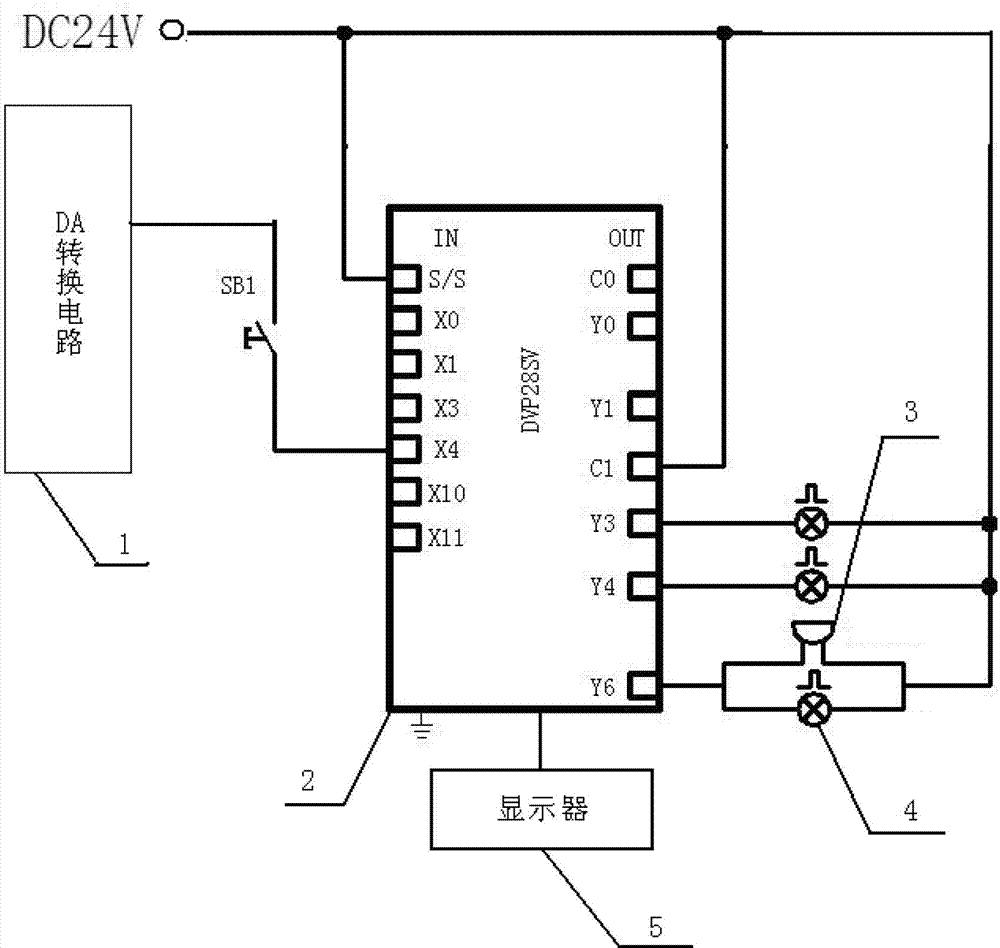

[0024] Specific implementation mode one: the following combination figure 1 with Figure 4 Describe this embodiment, the start-stop control device of hydrogen-oxygen carbon removal machine described in this embodiment, it comprises DA conversion circuit 1 and PLC controller 2,

[0025] The DA conversion circuit 1 is used to collect the voltage signal of the car battery, which is the battery of the car whose engine is to be cleaned, and the DA conversion circuit 1 transmits the converted analog voltage signal to the PLC controller 2, and the PLC controller 2 will collect the After the voltage signal is compared with the internal preset voltage threshold, a control signal is output to the hydrogen-oxygen decarbonizer to control the start or stop of the hydrogen-oxygen decarburizer.

[0026] In this embodiment, the PLC controller 2 first performs PID calculation on the collected analog voltage signal, converts it into a digital signal and sends it to the specified address for us...

specific Embodiment approach 2

[0027] Specific implementation mode two: the following combination figure 1 This embodiment will be described. This embodiment will further describe Embodiment 1. This embodiment also includes a buzzer 3 , and the alarm signal input end of the buzzer 3 is connected to the sound alarm signal output end of the PLC controller 2 .

[0028] When the PLC controller 2 detects that the voltage signal of the vehicle battery is lower than the voltage threshold, it can control the hydrogen-oxygen carbon removal machine to stop, and at the same time send an alarm signal to the buzzer 3 .

specific Embodiment approach 3

[0029] Specific implementation mode three: the following combination figure 1 Describe this embodiment, this embodiment will further explain Embodiment 1 or 2, this embodiment also includes a warning light 4, the warning signal input end of the warning light 4 is connected to the light warning signal output end of the PLC controller 2.

[0030] When the PLC controller 2 detects that the voltage signal of the vehicle battery is lower than the voltage threshold, it can control the hydrogen-oxygen decarburizer to stop, and simultaneously send an alarm signal to the buzzer 3 and the alarm lamp 4 .

[0031] In this embodiment, if the calculation result of the PLC controller 2 deviates from the set value during the operation of the hydrogen-oxygen carbon removal machine, it will stop immediately and send out an audible and visual alarm signal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com