White LED lamp secondary encapsulation structure capable of reducing blue-light hazards

A LED lamp and secondary packaging technology, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of cell apoptosis, poor uniformity and consistency, and temperature rise, and achieve reduced blue light radiation dose, uniform and soft colors, The effect of reducing potential harm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

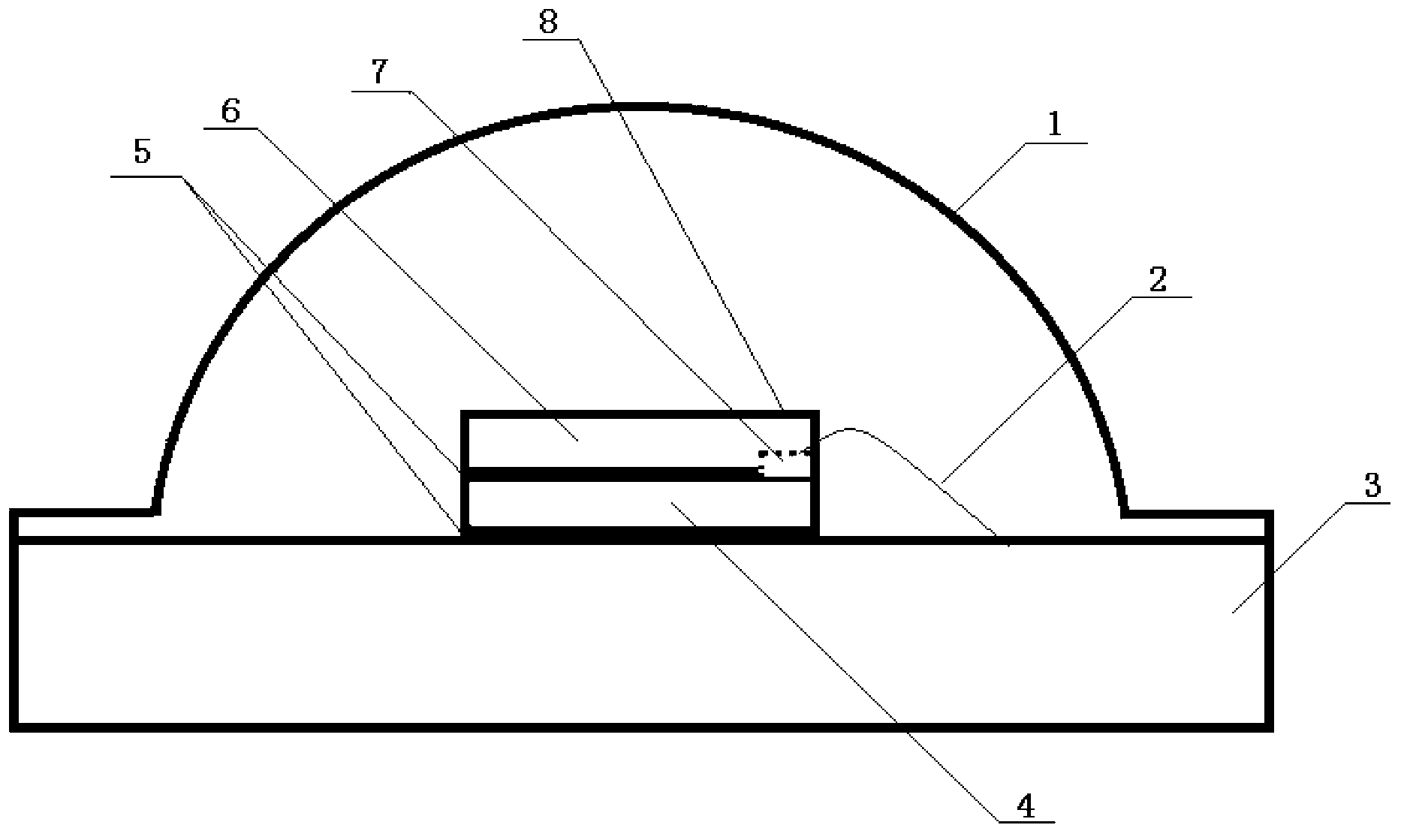

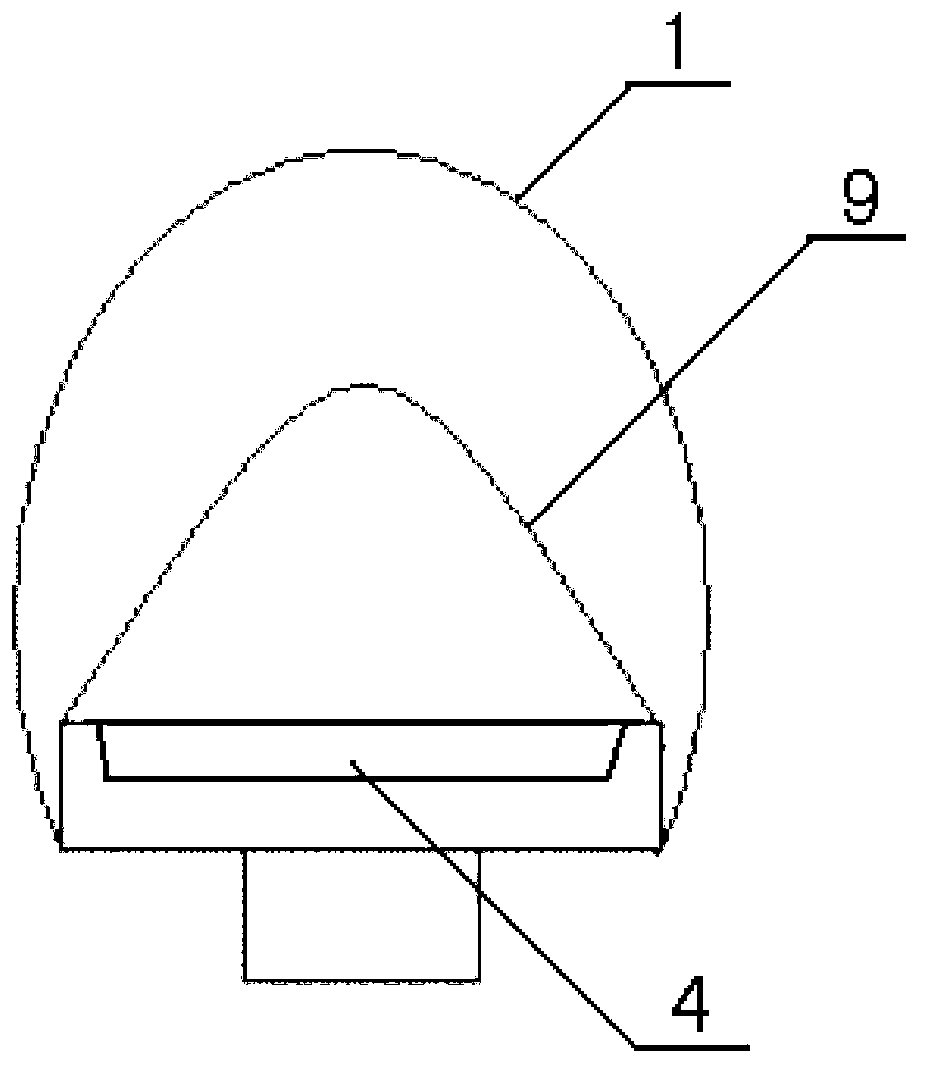

[0049] In this embodiment, the material of the fluorescent lamp cover is glass, and the shape is a curved surface.

[0050] In the luminous paint, by mass percentage, polyethylene oxide 5%, YAG yellow phosphor 0.5%, whitening powder and light diffusing powder 0.1%, transparent dispersant 2%, deionized water 92.4%.

[0051] In the YAG yellow phosphor layer 6 stacked on the blue LED chip 4, the content of the YAG yellow phosphor is 25%.

Embodiment 2

[0053] In this embodiment, the material of the fluorescent lamp cover is plastic, and the shape is a curved surface.

[0054]In the luminous paint, according to mass percentage, polyethylene oxide 5%, YAG yellow phosphor 5%, Al2O3 and glass powder 0.1%, transparent dispersant 2%, deionized water 87.9%.

[0055] In the YAG yellow phosphor layer 6 stacked on the blue LED chip 4, the content of the YAG yellow phosphor is 20%.

Embodiment 3

[0057] In this embodiment, the material of the fluorescent lamp cover is glass, and the shape is a curved surface.

[0058] In the luminous paint, by mass percentage, polyammonium methacrylate 3.5%, YAG yellow phosphor 10%, SiO 2 And whitening powder 1.5%, transparent dispersant 3%, deionized water 82%.

[0059] In the YAG yellow phosphor layer 6 stacked on the blue LED chip 4, the YAG yellow phosphor layer 6 contains 10% of the YAG yellow phosphor.

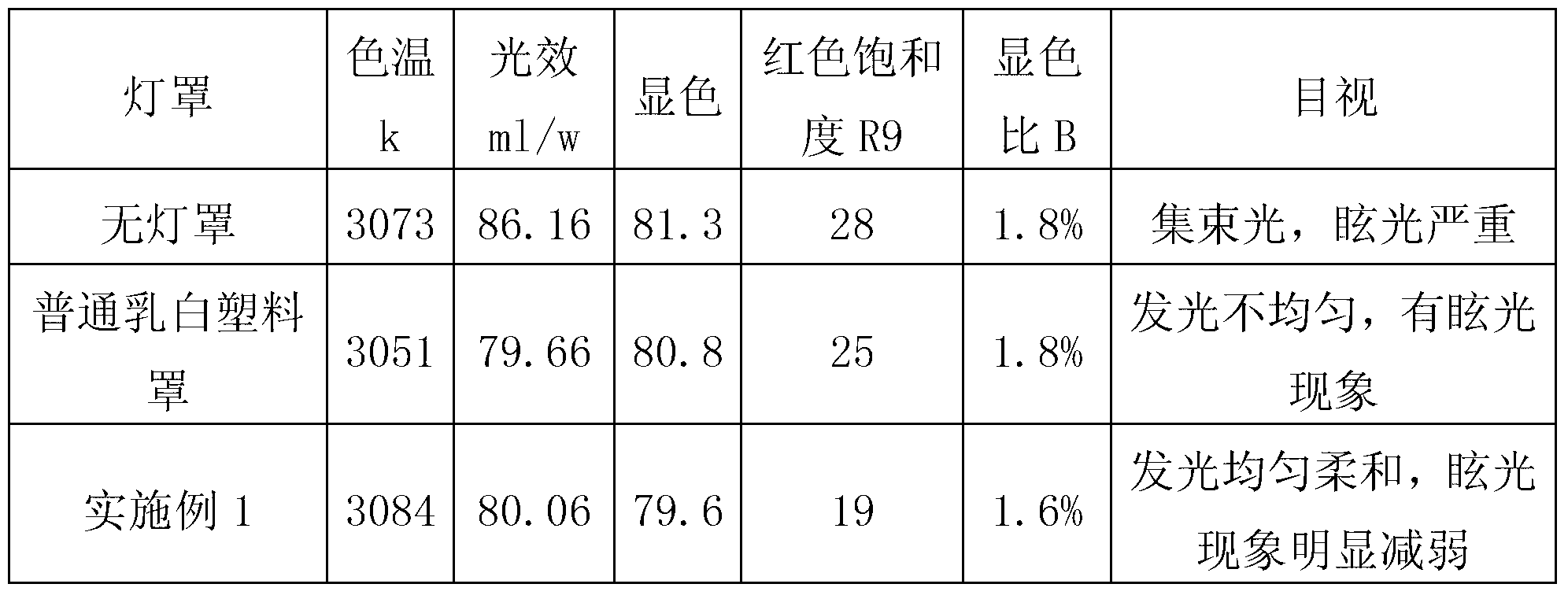

[0060] The luminous paint and YAG yellow fluorescent powder layer of the above-mentioned embodiment were respectively made into a 5W bulb lamp for testing, compared with no lampshade and ordinary opalescent plastic cover, the test data are as follows:

[0061] Table 1

[0062]

[0063]

[0064] It can be seen from the above table that the LED lamp adds a fluorescent outer lampshade coated with luminous paint, the color temperature decreases significantly, the light efficiency increases, the blue ratio also decreases signi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com