High-efficiency intelligent duplicate voltage compensation power saver

A technology of voltage compensation and power saving, applied in the direction of reactive power compensation, reactive power adjustment/elimination/compensation, etc., can solve problems such as poor power saving effect, unstable output, limited range of use, etc., and achieve remote manual control and real-time information communication, improving service life and safety, timely and efficient output power effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

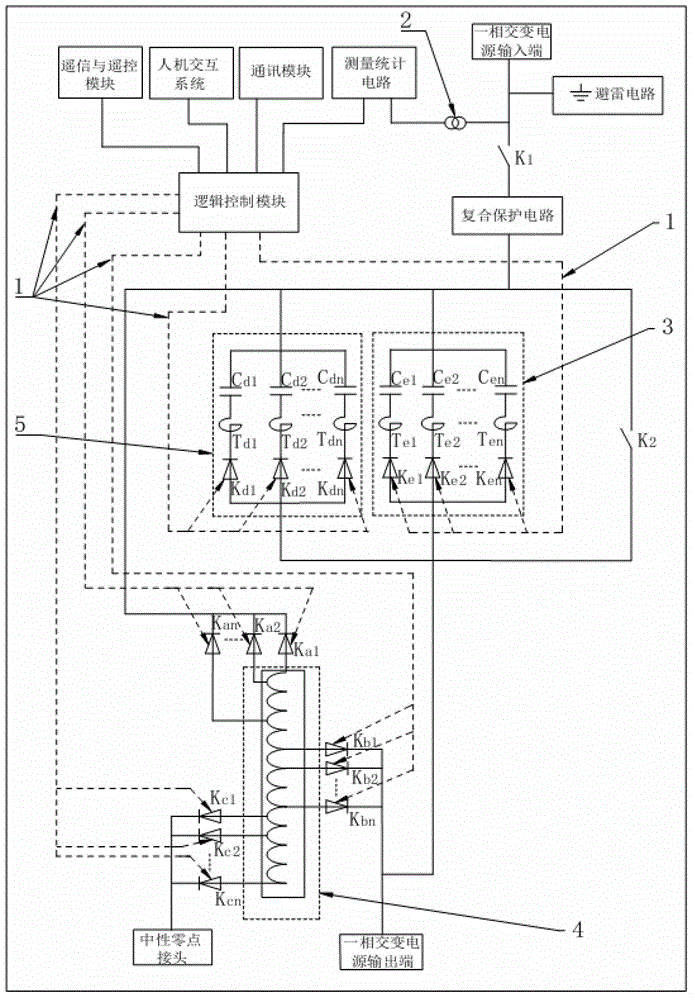

[0033] Such as figure 1 As shown, the technical solution adopted by the present invention is a high-efficiency intelligent compound voltage compensation power saver, which includes a logic control module and three power-saving processing systems for processing single-phase power in three-phase alternating power; each power saver The electric processing system is equipped with a double-type autotransformer coil 4, and each double-type autotransformer coil 4 is connected in parallel with the filter circuit, power factor improvement circuit and bypass circuit in the respective power-saving processing system, and then connected to the dry circuit of the AC power supply. The power input end of the alternating power main circuit is also connected in series with a composite protection circuit and a circuit breaker K1; the logic control module controls the zero adjustment switch Kc, the incoming line switch Ka and the three compound autotransformer coils 4 of the control circuit 1. Th...

Embodiment 2

[0035] On the basis of Example 1, in order to realize the regulation and control of the AC power supply, the present invention continuously adjusts the size of the output power according to the working conditions of the electrical appliances to achieve the purpose of saving electricity. The compound autotransformer coil 4 is equipped with 4 incoming line taps connected to the AC power input main circuit, 15 zero adjustment taps and 15 outgoing line taps connected to the AC power output main circuit, and three compound autotransformer The incoming line tap, outgoing line tap and zero adjustment tap in the transformer coil 4 are arranged at the same position of the coil; each incoming line tap is connected in series with an incoming line switch Ka connected to the logic control module, and each zero adjustment tap is connected in series with a The zero adjustment switch Kc connected to the logic control module, each outlet tap is connected in series with the outlet switch Kb conn...

Embodiment 3

[0037] On the basis of Embodiment 2, in order to effectively filter the clutter in the circuit and eliminate the influence of the current generated by the change of the working state of the electrical appliance on the power supply circuit, a preferred implementation mode also has each filter circuit composed of It consists of 8 parallel LC resonant circuits. Each LC resonant circuit is composed of a filter capacitor Cd, a reactor Td and a filter switch Kd in series. The LC resonant circuit has a resonant frequency that is similar to the harmonics of the electric equipment circuit and opposite Phase, in order to realize real-time detection of the working state of the electrical appliance to quickly adjust the output power, thereby efficiently adjusting the output power to achieve a better power-saving effect, the measurement and statistics circuit of the present invention communicates with the three alternating power supplies through three transformers 2 The input main circuit i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com