Anti-reflective film, anti-reflective film production method, polarization plate and image display device

一种防反射膜、反应性的技术,应用在偏振元件、化学仪器和方法、仪器等方向,能够解决低折射率层硬度不充分等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

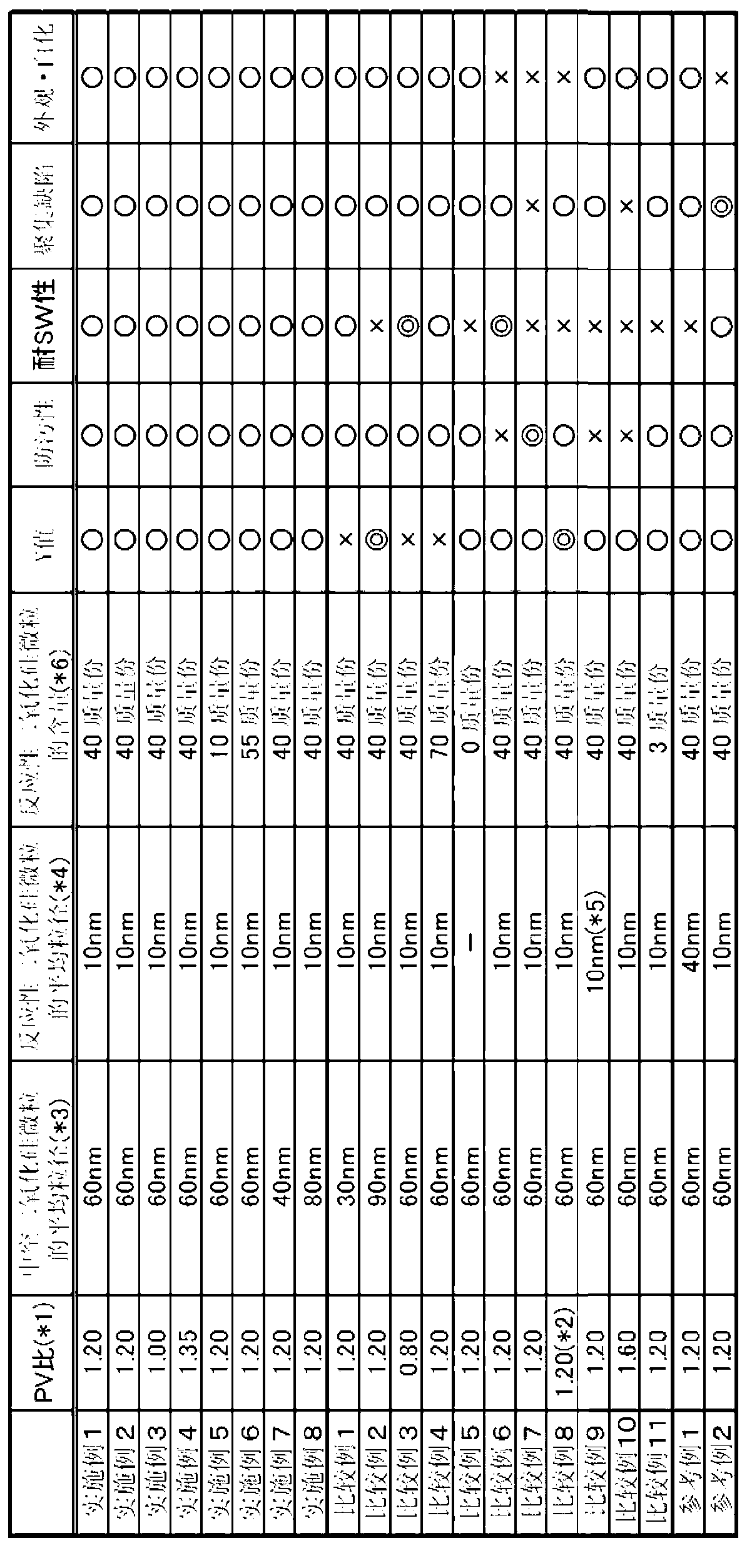

Examples

Embodiment 1

[0177] Wet weight 30g / m on one side of cellulose triacetate film (thickness 80μm) 2 (dry weight 15g / m 2 ) to apply a hard coat composition having the following composition to form a coating film. Next, the formed coating film was dried at 50°C for 30 seconds and irradiated with 50mJ / cm 2 UV rays form a hard coating.

[0178] (composition for hard coat)

[0179] urethane acrylate

[0180] (BS371, product made by Arakawa Chemical Co., Ltd., solid content 70%) 4.0 parts by mass

[0181] (UV1700B, manufactured by Nippon Gosei Co., solid content 70%) 12.0 parts by mass

[0182] 0.6 parts by mass of a polymerization initiator (Irgacure 184; manufactured by Ciba Seika Co., Ltd.)

[0183] 5.6 parts by mass of methyl ethyl ketone

[0184] 0.2 parts by mass of leveling agent (Defensa MCF350-5, manufactured by DIC Corporation, solid content 5%)

[0185] Next, a coating liquid for a low-refractive index layer having the following composition was coated on the formed hard coat laye...

Embodiment 2

[0196] An antireflection film was obtained in the same manner as in Example 1 except that dipentaerythritol hexaacrylate (DPHA) was used instead of PETA for the coating liquid for a low refractive index layer.

Embodiment 3

[0198] An antireflection film was obtained in the same manner as in Example 1 except that the amount of hollow silica fine particles mixed in the coating liquid for a low refractive index layer was 500.0 parts by mass.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com