Macromolecular organic guazatine and organic silicon derivative leather antimicrobial mildew preventive and preparation method thereof

An antibacterial and antifungal agent, antibacterial and antifungal technology, applied in botanical equipment and methods, biocides, chemicals for biological control, etc. Lack of effective means to achieve less irritating effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

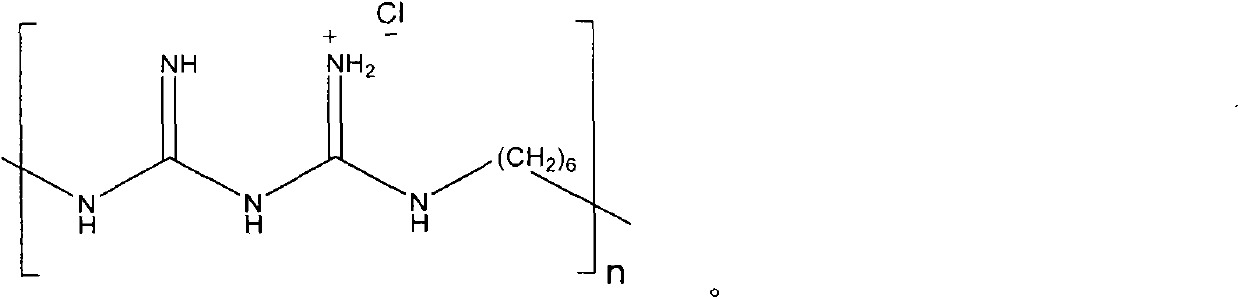

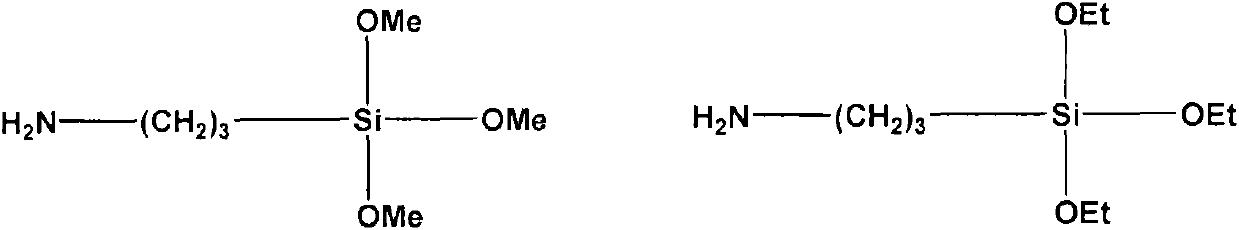

[0034] Add 1 part of macromolecular organic biguanide salt with a viscosity average molecular weight of 1000 to 3 parts of tetrahydrofuran, stir and dissolve at 35-45°C for 30-60 minutes; after the macromolecular organic biguanide salt is completely dissolved, add 0.5 part of organosilane 3 -Aminopropyltrimethoxysilane was dissolved in 3 parts of tetrahydrofuran and added to the reactor at one time, the temperature was raised to 60-65°C, and the reaction was stirred for 3-8 hours; the reaction was stopped, and the system was evaporated to remove tetrahydrofuran under reduced pressure; the obtained The creamy or soapy solid is the product.

Embodiment 2

[0036] Add 3 parts of macromolecular organic biguanide salt with a viscosity average molecular weight of 3000 to 8 parts of tetrahydrofuran, stir and dissolve at 35-45°C for 30-60 minutes; after the macromolecular organic biguanide salt is completely dissolved, add 3 parts of organosilane 3 -Aminopropyltriethoxysilane is dissolved in 5 parts of methanol and added to the reactor at one time, the temperature is raised to 60-65 ° C, and the reaction is stirred for 3-8 hours; the reaction is stopped, and the system is evaporated under reduced pressure to remove tetrahydrofuran And methanol; the resulting creamy or soapy solid is the product.

Embodiment 3

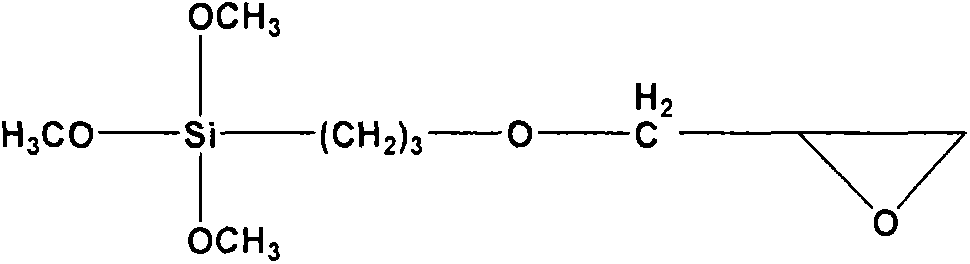

[0038] Add 5 parts of macromolecular organic biguanide salt with a viscosity average molecular weight of 4000 to 10 parts of ethanol, stir and dissolve at 35-50°C for 30-60 minutes; after the macromolecular organic biguanide salt is completely dissolved, add 10 parts of organosilane 3 - Glycidyl etheroxypropyl trimethoxysilane was dissolved in 5 parts of ethanol and added to the reactor at one time, the temperature was raised to 75-78°C, and the reaction was stirred for 3-8 hours; the reaction was stopped, and the system was evaporated under reduced pressure Remove ethanol; the resulting paste or soap-like solid is the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com