Liquid injection type micro point fog spraying device

A technology of liquid injection and liquid input, applied in the direction of liquid injection device, injection device, etc., to achieve the effects of superior ease of cleaning, simplified development, and superior start and stop characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

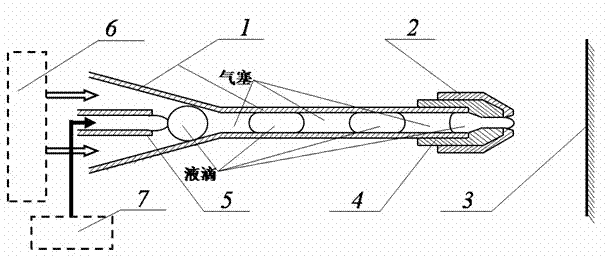

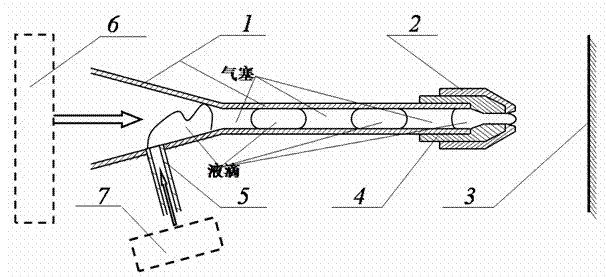

[0044] see figure 1 with figure 2 , the liquid injection type micro-spray spray device includes a precise liquid input device 7, a gas delivery device 6, a gas delivery conduit 1, a nozzle and a liquid delivery conduit 5, and is characterized in that the gas delivery conduit 1 is composed of an inlet constriction section connected to a pipe section of equal cross-section , and access the infusion conduit 5 at the center or wall of its inlet constriction section; the nozzle is composed of a built-in nozzle 4 surrounded by an external nozzle 2, and the built-in nozzle 4 is set on the air conduit 1 The end of the equal-section pipe section; the inlet constriction section of the gas delivery conduit 1 is connected to the gas delivery device 6 , and the infusion conduit 5 is connected to the precise liquid input device 7 .

[0045]

Embodiment 2

[0047] This embodiment is basically the same as Embodiment 1, and the special features are:

[0048] The external nozzle 2 and the built-in nozzle 4 are connected with a detachable structure or the built-in nozzle 4 is replaced with a corresponding paint layer; or the downstream part of the equal-section pipe section of the gas delivery conduit 1 is completely removed.

[0049] The equal-section pipe section of the gas delivery conduit 1, the inner diameter of the infusion conduit 5 and the built-in nozzle 4 are all on the order of millimeters or less; The section and its downstream form a blocked flow. As the working medium, the gas can drive the liquid jet to break and move, and at the same time, it can be used to clean the pipeline.

[0050] The precise liquid input device 7 can provide continuous or pulsed or intermittent irregular liquid input, and its precision is controlled at the level of microliter or below, so as to provide high-frequency multi-point or single-point...

Embodiment 3

[0054] see figure 1 , The liquid injection micro-spray spraying device is composed of a precise liquid input device 7, a gas delivery device 6, an air delivery conduit 1, an external nozzle 2, a built-in nozzle 4 and an infusion conduit 5. The precise liquid input device 7 and the gas delivery device 6 provide stable viscous liquid and gas supply respectively, the gas directly enters the gas delivery conduit 1, and the liquid enters the gas delivery conduit 1 through the infusion conduit 5; the gas delivery conduit 1 is connected to the built-in nozzle 4 downstream The built-in nozzle 4 is covered with an external nozzle 2, and the liquid plug separated by air bubbles in the gas delivery conduit 1 sprays to the target substrate 3 through the built-in nozzle 4 and the external nozzle 2 to realize the spraying process.

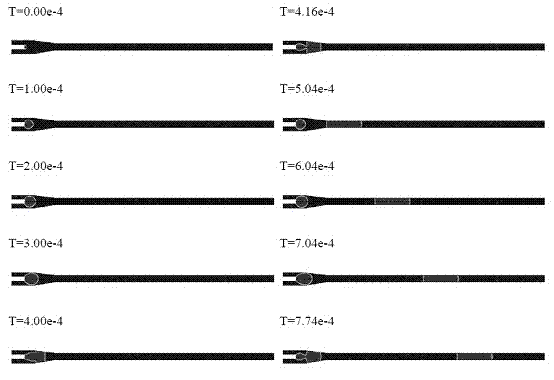

[0055] see figure 2 , the simulation diagram of the central liquid injection pipeline, and the dimensions are as indicated in the label. The media are air an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com