Heat-insulated constant-temperature plastic profile containing shape-stabilized phase change material and production process of heat insulated constant-temperature plastic profile

A technology of plastic profiles and phase change materials, which is applied in the direction of heat exchange materials, layered products, synthetic resin layered products, etc., can solve the problems such as the great difference between the phase change process and the thermal performance of the phase change, and achieve the latent heat of phase change Larger, lower supercooling, and solve the effect of leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

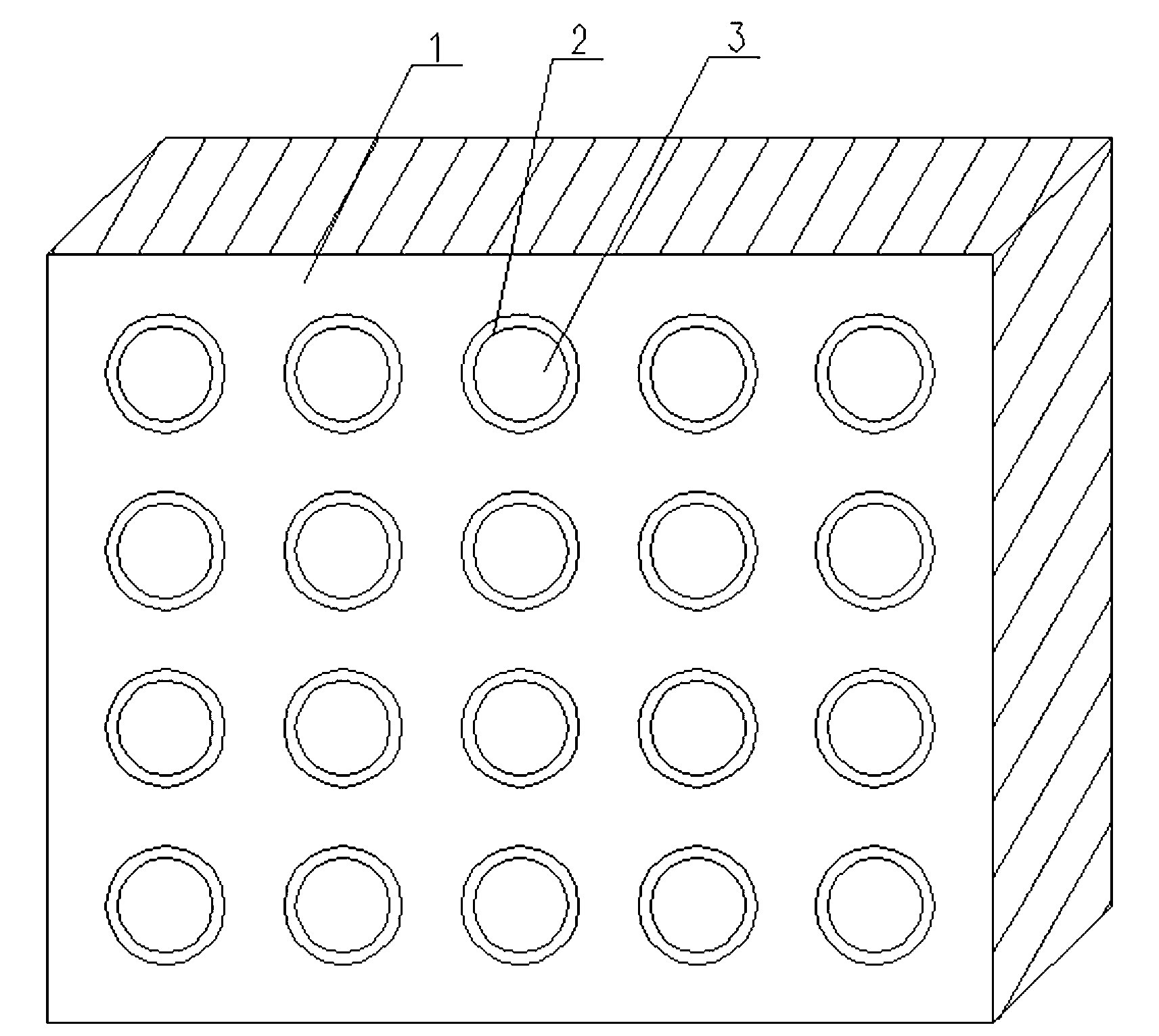

[0026] B. Preparation of thermoplastic profile 1 with concave holes 2: prepare thermoplastic profile 1 with multiple concave holes 2 by extrusion blow molding, extrusion temperature is 130-190°C, blowing air pressure is 0.5- 2Mpa;

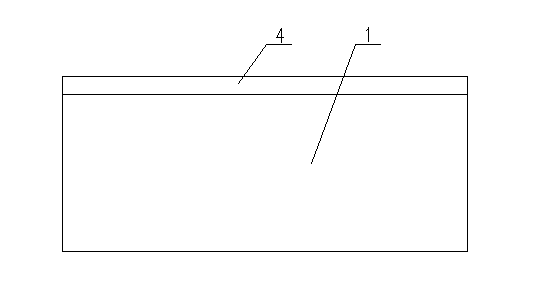

[0027] C. Encapsulation of activated carbon 3 with sodium sulfate adsorbed on the shaped phase change material: place the activated carbon 3 adsorbed with sodium sulfate in the concave hole 2, heat the pre-extruded thermal plastic sheet covering layer 4 to 120-190°C, The thermal plastic sheet covering layer 4 is closely attached to the upper end of the thermal plastic profile 1 with the concave hole 2, and the concave hole 2 is sealed by applying pressure at a pressure of 0.5-1.5Mpa to obtain a thermally insulating and constant temperature plastic profile.

[0028] The thermoplastic profile 1 can be polypropylene, polyethylene or polystyrene.

Embodiment 1

[0030] The production process of heat-insulating and constant-temperature plastic profiles containing shaped phase-change materials includes the following steps:

[0031] A. Preparation of activated carbon 3 with sodium sulfate adsorbed on the stereotyped phase change material: according to 142 parts of Na 2 SO 4 with 180 H 2 O (molar ratio 1:10), formulated as Na 2 SO 4 Saturated solution; add 100 parts of activated carbon to 30-80 parts of Glauber's salt Na 2 SO 4 Saturated solution, so that Na 2 SO 4 The saturated solution is completely absorbed by activated carbon;

[0032] B. Preparation of a thermoplastic profile 1 with concave holes 2: a polyethylene hollow profile with a plurality of concave holes 2 is prepared by extrusion blow molding, the distance between the concave holes 2 is 10mm, and the depth of the concave holes 2 is 10mm, the radius of concave hole 2 is 5mm, the extrusion temperature is 130-190℃, and the blowing air pressure is 1Mpa;

[0033] C. E...

Embodiment 2

[0036] The production process of heat-insulating and constant-temperature plastic profiles containing shaped phase-change materials includes the following steps:

[0037] A. Preparation of activated carbon 3 with sodium sulfate adsorbed on the stereotyped phase change material: according to 142 parts of Na 2 SO 4 with 180 H 2 O (molar ratio 1:10), formulated as Na 2 SO 4 Saturated solution; add 100 parts of activated carbon to 30-80 parts of Glauber's salt Na 2 SO 4 Saturated solution, so that Na 2 SO 4 The saturated solution is completely absorbed by activated carbon;

[0038] B. Preparation of a thermoplastic profile 1 with concave holes 2: a polyethylene hollow profile with a plurality of concave holes 2 is prepared by extrusion blow molding, the distance between the concave holes 2 is 15mm, and the depth of the concave holes 2 is 15mm, the radius of concave hole 2 is 10mm, the extrusion temperature is 130-190℃, and the blowing air pressure is 1Mpa;

[0039] C. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com