Ship for desalting sea sand and method for desalting sea sand on ship

A sea sand and cabin technology, applied to special-purpose ships, warships, motor vehicles, etc., can solve the problems of rising transportation costs and not being properly resolved, and achieve the effect of low cost, simple structure and good desalination effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

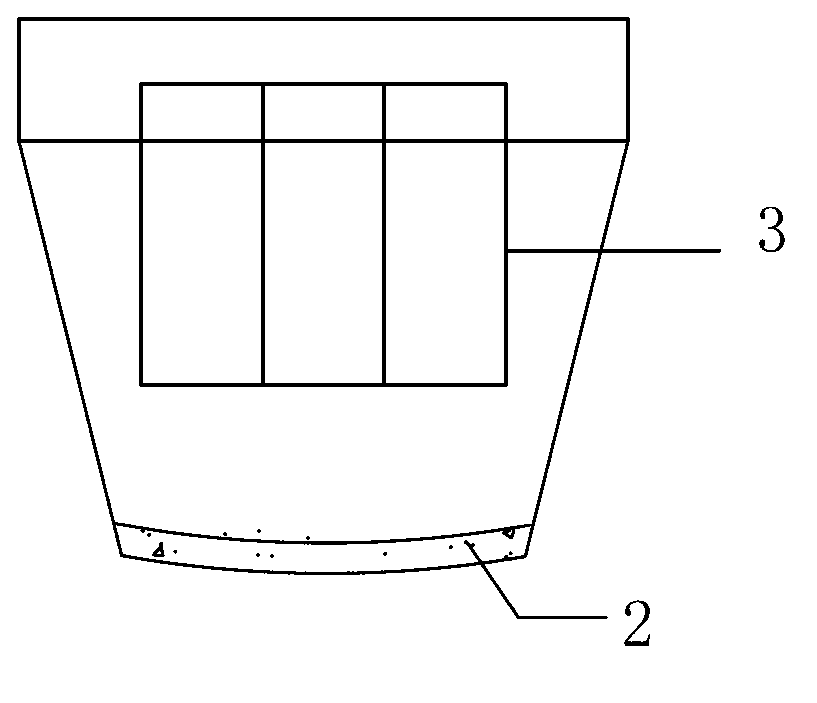

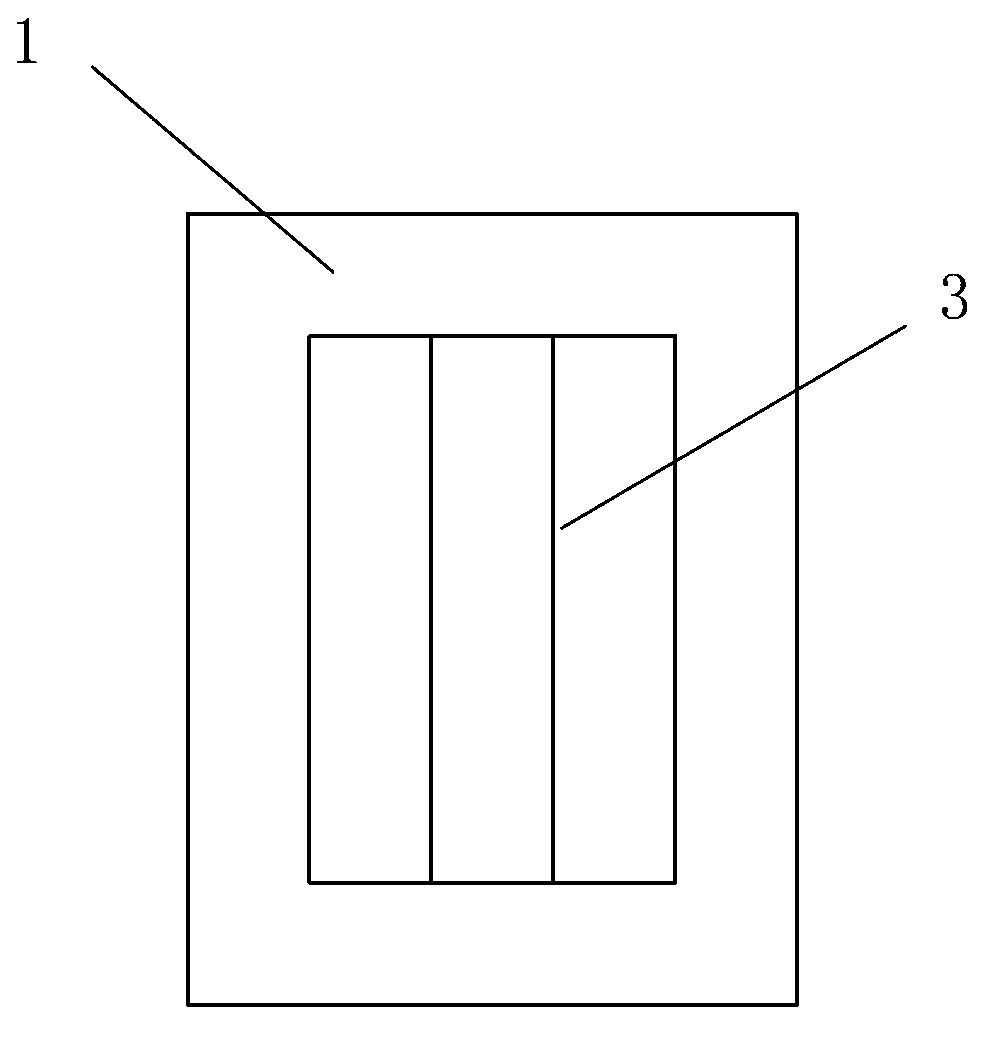

[0039] like Figure 1-2 In the example shown, a primary partition 3 is provided along the length direction of the hull, which can divide the cabin into several long and narrow strip-shaped spaces extending along the length direction of the hull.

[0040] The filtering drainage facility of the present invention may be a geotextile laid on the bottom of the bilge and matching drainage pipes. The water after desalination of sea sand can pass through the fiber gap of the geotextile and be discharged from the sea sand body, and the geotextile will retain the desalinated sea sand. Moisture passing through the geotextile is drained by the drainage pipe.

[0041] The filtration and drainage facility of the present invention can also be an anti-filter layer laid on the bilge and a drainage pipe matched therewith, and the water after desalination of sea sand passes through the anti-filter layer and is discharged from the drainage pipe. The reverse filter layer is a graded gravel layer...

Embodiment 2

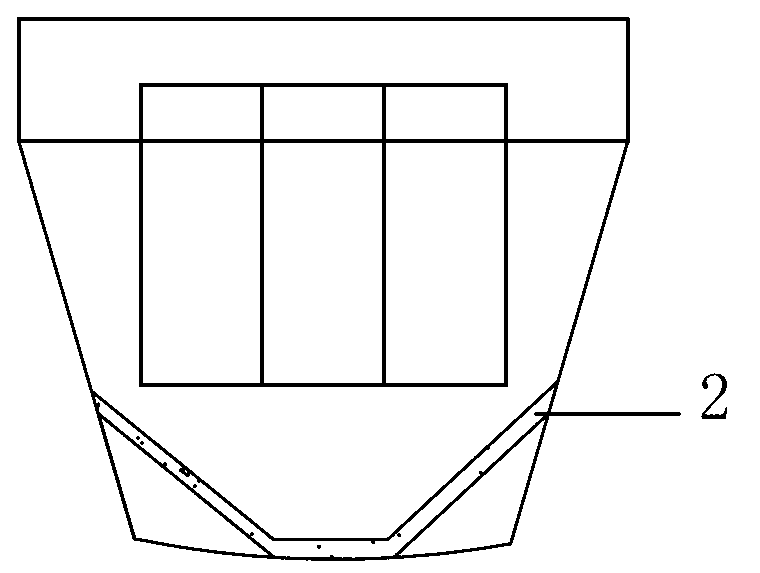

[0045] like Figure 3-4 In this example shown, a primary partition 3 is arranged along the length direction of the hull, and a secondary partition 4 is also provided along the width direction of the hull. The primary partition and the secondary partition are fixedly connected and arranged vertically. Several block spaces are formed.

[0046] The present invention can properly determine the quantity of the primary partition and the secondary partition according to the actual situation of the hull and the transportation needs, and divide the cabin into strip-shaped or L-shaped or #-shaped partitioned areas.

[0047]When transporting sea sand, the loaded sea sand is relatively separated and packed in different areas. During the subsequent sea sand desalination treatment, fresh water is injected into each divided area, and the sea sand in different areas is desalinated. According to the needs or actual loading characteristics, more fresh water can be properly added to the divided...

Embodiment 3

[0058] In the method of the present invention, adding fresh water, washing and desalination and draining can be carried out simultaneously, and fresh water is preferably injected into the cabin from the top of the cabin, and the injection amount of fresh water should be less than 100 times of the sea sand volume. When the fresh water is injected, the fresh water seeps downward from the sea sand body, fills the gaps between the sand particles, and desalinizes the sea sand. The water after desalination of the sea sand that seeps to the bottom of the cabin is discharged through the filter drainage facility, and the sea sand is also discharged at the same time. Water originally present in the body. The desalinated water is discharged in time, which can avoid a large amount of water accumulation in the cabin, reduce the load bearing of the hull, and is conducive to safe operation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com