A pulverized coal pressurized conveying system and process

A conveying system and technology for pulverized coal, which is used in conveyors, conveying bulk materials, transportation and packaging, etc., can solve the problems of expensive sintered metal ventilation plates, inability to accurately control the flow of pulverized coal, and difficulty in stable dense-phase transportation of pulverized coal. problems, to achieve the effect of saving construction and operating costs, reducing equipment and instrument control investment, and facilitating manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to better illustrate the present invention, the technical solutions in the embodiments of the present invention are clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

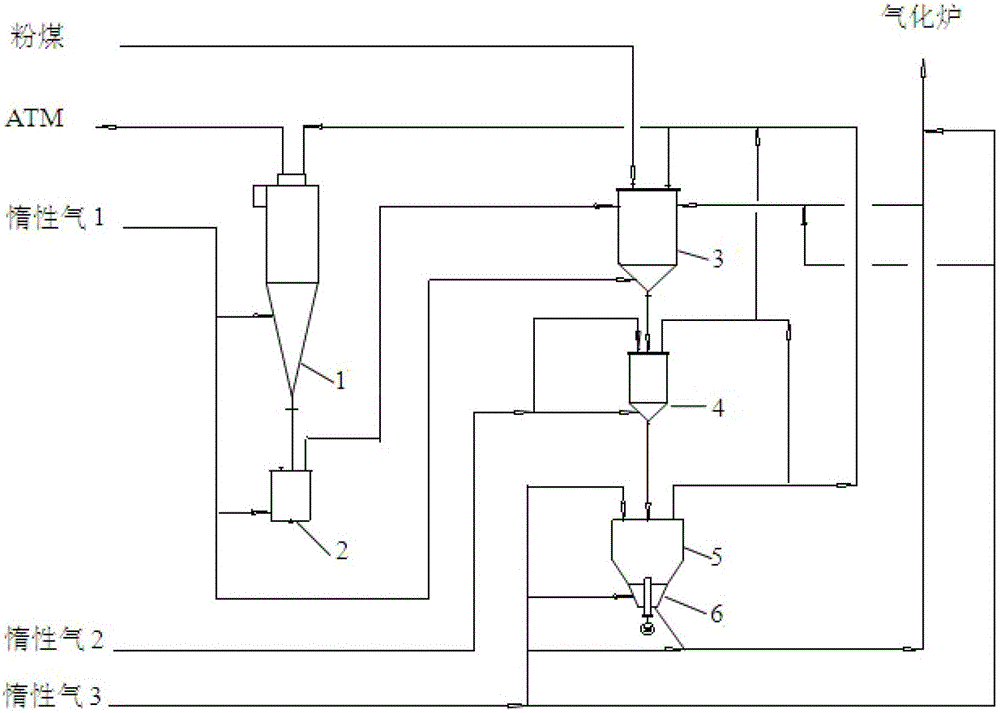

[0035] Such as figure 1 As shown, the pulverized coal pressurized conveying process system includes a bag filter 1 , a pulverized coal conveying tank 2 , a pulverized coal low-pressure storage tank 3 , a pulverized coal lock hopper 4 , a pulverized coal high-pressure storage tank 5 and a rotary feeder 6 .

[0036] Wherein, bag filter 1 selects the commercially available product that ash hopper has ventilation equipment according to design condition.

[0037] The pulverized coal delivery tank 2 is used to transport the pulverized coal filtered by the bag filter 1. It is composed of a tank body with an upper discharge pipe inside; ~4 imports take over.

[0038] The pulverized coal low-pressure storage tank 3 is used to store pulve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com